Multi-function ship bottom sealant and production method thereof

A multi-functional sealant technology, applied in the field of sealants, can solve the problems affecting the use of sealants, easy to breed microorganisms, and poor toughness of sealants, so as to improve the effect of sound insulation, avoid incompatibility and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of multifunctional ship bottom sealant

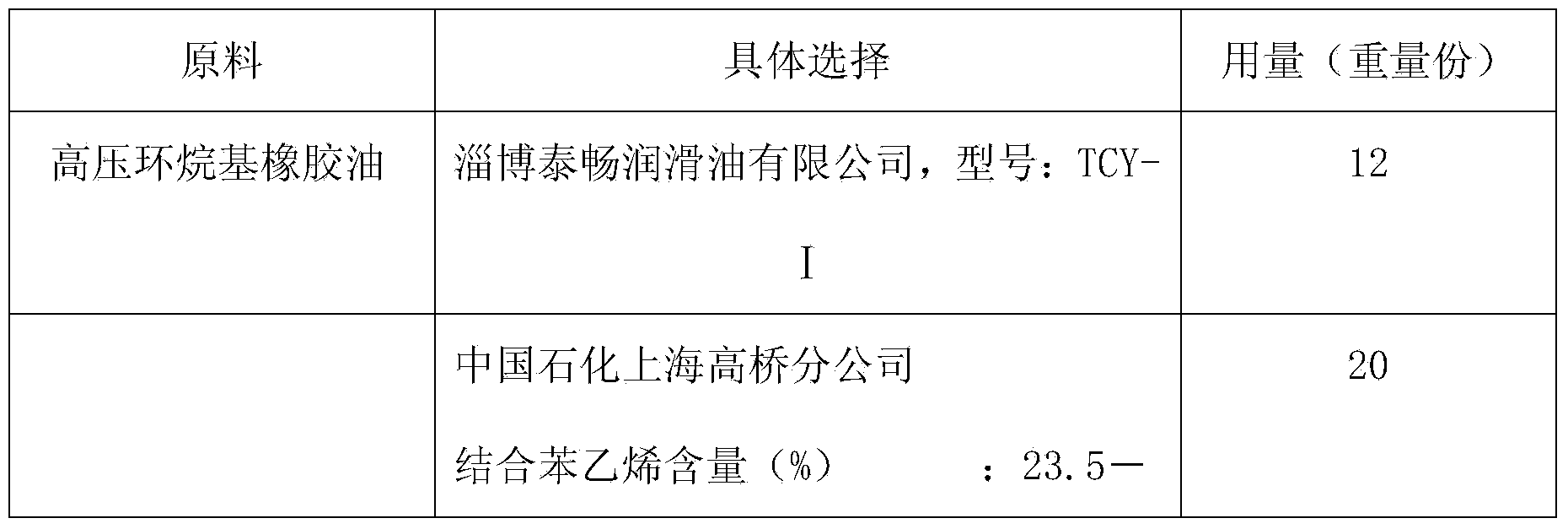

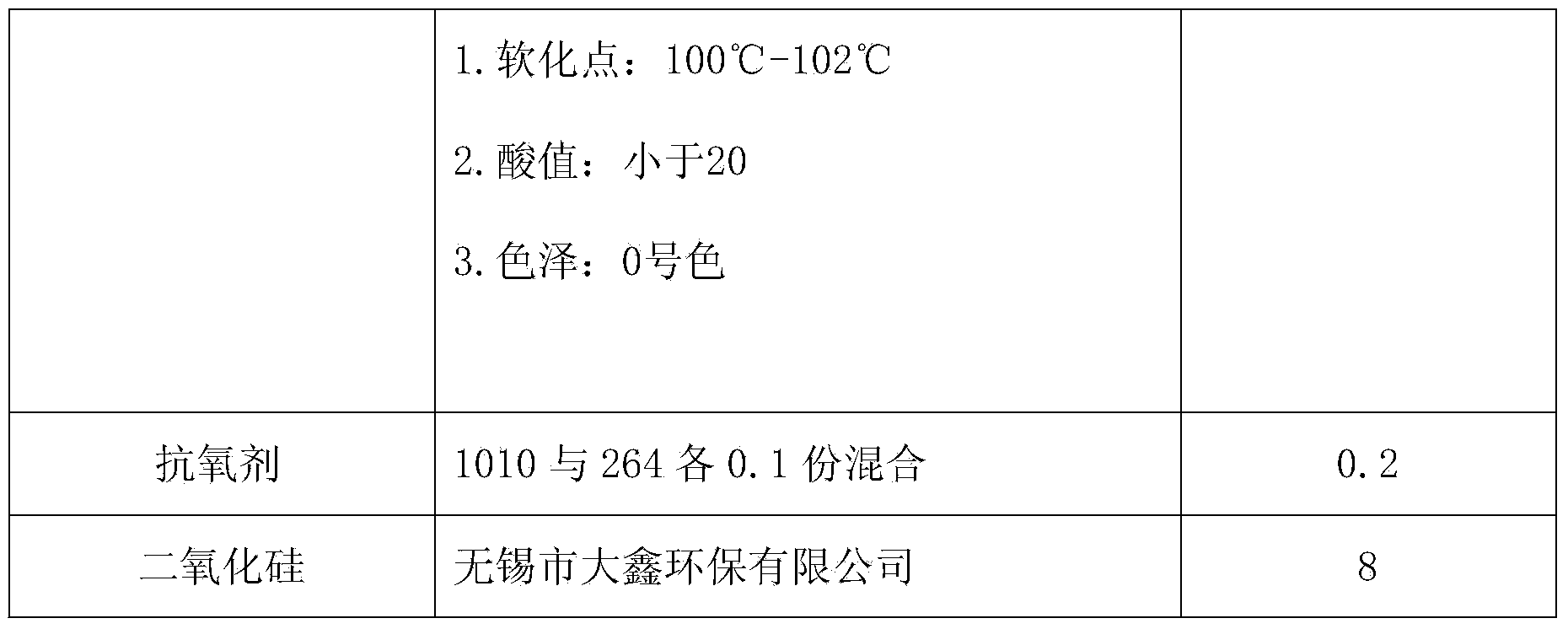

[0018] raw material:

[0019]

[0020]

[0021]

[0022] (1) Preparation method:

[0023] Add part of high-pressure naphthenic rubber oil to the reaction kettle first, add S-SBR according to the weight ratio, then add antioxidant, heat to 160°C, start stirring, and replace the gas in the kettle with nitrogen; wait for the S-SBR to dissolve Completely add bisphenol A epoxy resin in proportion, and then add hydrogenated rosin resin after the temperature is constant, stir for 5 minutes and then add PB bromide and silicon dioxide; vacuum the kettle to keep it at -0.02mPa; stir for 20 minutes Lower the temperature of the kettle from left to right; discharge the material after the temperature drops to 120°C.

[0024] (2) Product performance parameters:

[0025] Appearance: white solid glue

[0026] Non-volatile matter: 100%

[0027] Purity: heated to 160°C, all through 80-mesh sieve

[0028]...

Embodiment 2

[0037] Embodiment 2: the preparation of multifunctional ship bottom sealant

[0038] raw material:

[0039]

[0040]

[0041] (4) Preparation method:

[0042] Add part of high-pressure naphthenic rubber oil to the reaction kettle first, add S-SBR according to the weight ratio, then add antioxidant, heat to 160°C, start stirring, and replace the gas in the kettle with nitrogen; wait for the S-SBR to dissolve Completely add bisphenol A epoxy resin in proportion, and then add hydrogenated rosin resin after the temperature is constant, stir for 5 minutes and then add PB bromide and silicon dioxide; vacuum the kettle to keep it at -0.03mPa; stir for 20 minutes Lower the temperature of the kettle from left to right; discharge the material after the temperature drops to 120°C.

[0043] (5) Product performance parameters:

[0044] Appearance: white solid glue

[0045] Non-volatile matter: 100%

[0046] Purity: heated to 160°C, all through 80-mesh sieve

[0047] Melting tem...

Embodiment 3

[0056] Embodiment 3: the preparation of multifunctional ship bottom sealant

[0057] raw material:

[0058]

[0059]

[0060]

[0061] (7) Preparation method:

[0062] Add part of high-pressure naphthenic rubber oil to the reaction kettle first, add S-SBR according to the weight ratio, then add antioxidant, heat to 160°C, start stirring, and replace the gas in the kettle with nitrogen gas; wait for the S-SBR to dissolve Completely add bisphenol A epoxy resin in proportion, and then add hydrogenated rosin resin after the temperature is constant, stir for 5 minutes and then add PB bromide and silicon dioxide; vacuum the kettle to keep it at -0.02mPa; stir for 20 minutes Lower the temperature of the kettle from left to right; discharge the material after the temperature drops to 120°C.

[0063] (8) Product performance parameters:

[0064] Appearance: white solid glue

[0065] Non-volatile matter: 100%

[0066] Purity: heated to 160°C, all 80-mesh sieves pass through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com