Preparation method of organosilicon-modified amphoteric polyurethane aqueous dispersion

A polyurethane water dispersion and silicone technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of pH sensitivity in the application environment, achieve easy control of the production process, increase the application range, and avoid severe exothermic phenomena Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

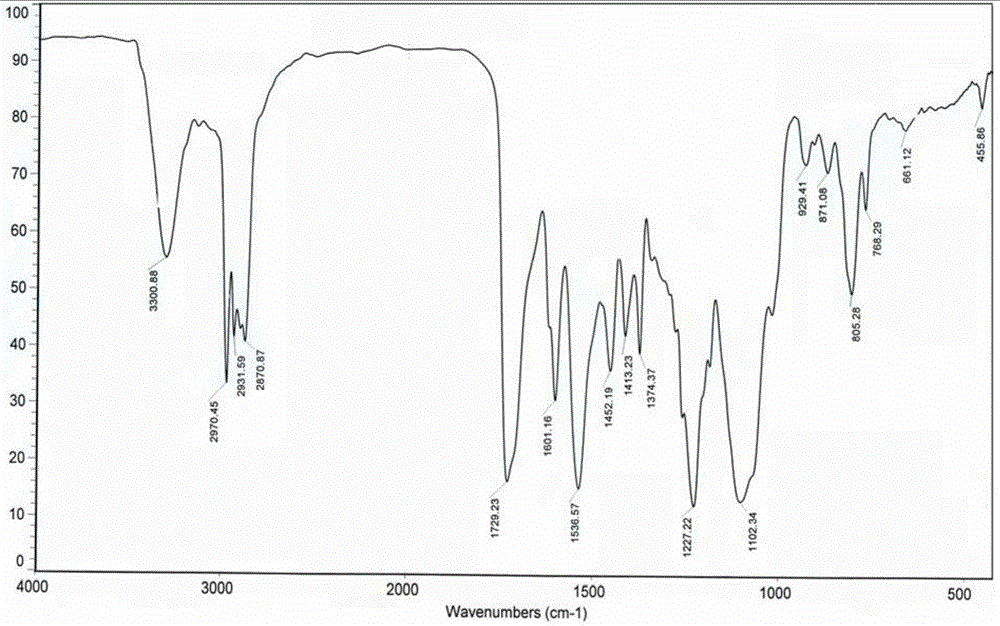

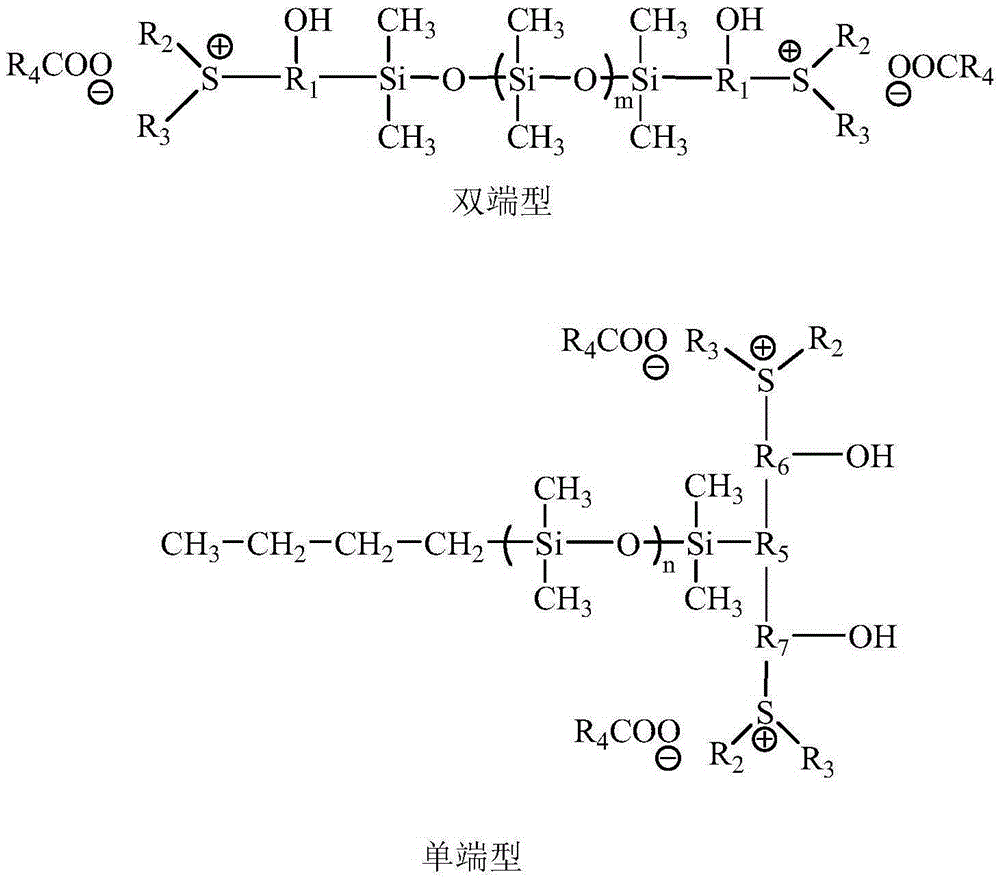

[0030] Example 1 (cationic silicone content=14.1%, COOH%=1.3%, NCO / OH=2.86:1)

[0031]

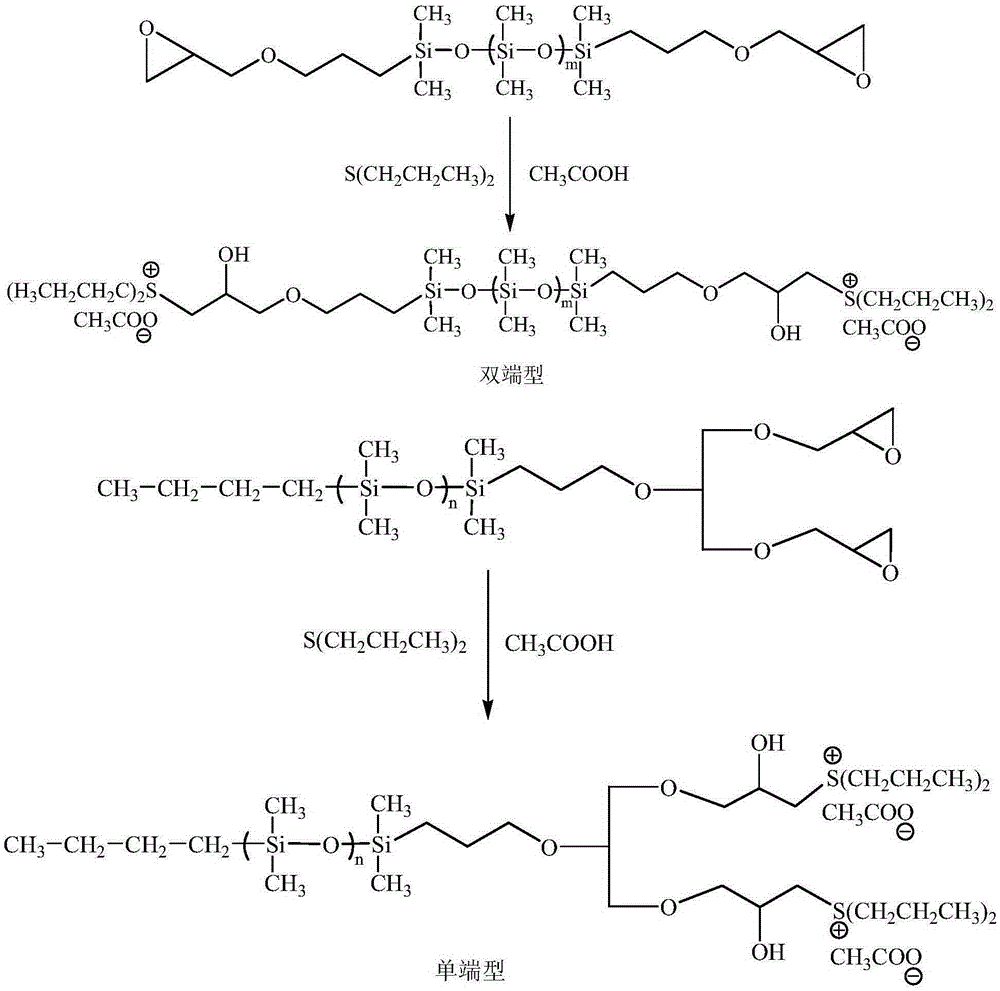

[0032] 1. Synthesis of cationic silicone:

[0033] Equilibrium reaction: using trifluoromethanesulfonic acid as a catalyst, tetramethyldihydrosiloxane and octamethylcyclotetrasiloxane (D 4 ) for polymerization reaction, nitrogen protection is used during the reaction process, the reaction temperature is 65° C., and the reaction time is 20 h to obtain α,ω-bissilylhydrogen-terminated polysiloxane. The molar ratio of the above two reactants in the equilibrium reaction depends on the molecular weight of the final product or the silicon hydrogen content. According to the above reaction formula, the molecular weight design formula (taking tetramethyldihydrogensiloxane as the end-capping agent, the dosage is 1mol as an example) is as follows, the design molecular weight of polysiloxane=the molecular weight of the end-capping agent (134)+D 4 Molecular weight (296)×D 4 The amount of substance...

Embodiment 2

[0055] Example 2 (cationic silicone content=21.3%, COOH%=1.44%, NCO / OH=2.5:1)

[0056]

[0057] 1. Synthesis of cationic silicone:

[0058] Hydroxyl protection: at room temperature, first add hexamethyldisilazane dropwise to glycerol, raise the temperature of the reaction system to 90-120°C, and continue to react at this temperature for 4-8 hours, stop the reaction, and distill it off under reduced pressure Excessive hexamethyldisilazane to obtain 1,3-bis(trimethylsilyl)oxyl-2-propanol, and the molar ratio of feeding in the hydroxyl protection reaction process is: glycerol:hexamethyldisilazane Alkane=1:1~1.1.

[0059]Alkylation reaction: At room temperature, slowly add 1,3-bis(trimethylsilyl)oxy-2-propanol dropwise to the tetrahydrofuran solution containing sodium hydride, start stirring and slowly raise the temperature to 40-60°C for reaction 2h until no hydrogen gas is generated; after cooling the reaction system to 0°C, start stirring and slowly add allyl bromide dropw...

Embodiment 3

[0084] Example 3 (cationic silicone content=24.4%, COOH%=1.34%, NCO / OH=2.5:1)

[0085]

[0086] Prepolymerization: In a three-necked flask equipped with a stirrer and a thermometer, add 250g diphenylmethane diisocyanate, 75g cationic silicone (M) of structure (I) n =1500) and 50 g of cationic silicone (M n=1000), heated up to 70°C and reacted for 1.2h; then added 100g of polyether diol (M n =2000), the reaction was continued for 1.5h at the same temperature. Add 22.2g of dimethylolbutyric acid into the reaction system, react at 70°C for 1h, then add 6.20g of ethylene glycol and react at 70°C for 1h, then use the standard di-n-butylamine back titration method to analyze the prepolymer The content of isocyanate group, when the content of isocyanate group reaches the theoretical value of 11.83%, the reaction is terminated, and the main chain contains tertiary sulfonium group, ether group, urethane group, carboxyl group and polysiloxane segment, and the side chain contains po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com