Preparation method of hydrophobic separating membrane

A technology for hydrophobic and separation membranes, which is applied in the field of preparation of hydrophobic separation membranes. It can solve the problems of narrow material selection range, low comprehensive performance of membranes, and poor hydrophobic stability, and achieve easy scale-up and large-scale production, high hydrophobicity, Effect of good hydrophobic stability and separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 0.5g of polyethersulfone (PES, E6020P, BASF) and 0.031g of p-methoxyphenol (as a polymerization inhibitor), add 1.0ml of TEMAc-8 monomer and 49ml of DMAC into the mixture, and pass through the magnetic force at 60°C Stirring for 12 hours gave a homogeneous solution. Blow nitrogen into the homogeneous solution for 20 minutes, seal it for storage, and then place it in 60 The irradiation reaction was carried out in the Co source chamber, the irradiation dose was 5.1 kGy, and the dose rate was 1.5 kGy / h. After taking out, use methanol as the precipitant to fully precipitate and suction filter, and use F113 as the extract to perform Soxhlet extraction on the filtrate for 72 hours to remove the homopolymer, and obtain graft polymer 1 with a graft rate of 7.06%. .

[0031] Weigh 0.5 g of graft polymer 1 and 49.5 g of trifluorotoluene into a conical flask, ultrasonicate at room temperature for 30 min, and place at 60° C. for 24 h to obtain a uniformly dispersed film-for...

Embodiment 2

[0033] The irradiation grafting conditions were the same as those in Example 1, wherein the amount of monomer TEMAc-8 and solvent DMAC added were 4.0ml and 46ml, respectively, to obtain graft polymer 2 with a grafting rate of 30.67%. The hydrophobic separation membrane 2 was obtained by using the pretreatment method and modification conditions of the base membrane in Example 1, and the membrane distillation desalination performance of the hydrophobic separation membrane 2 was measured by the method in Example 1.

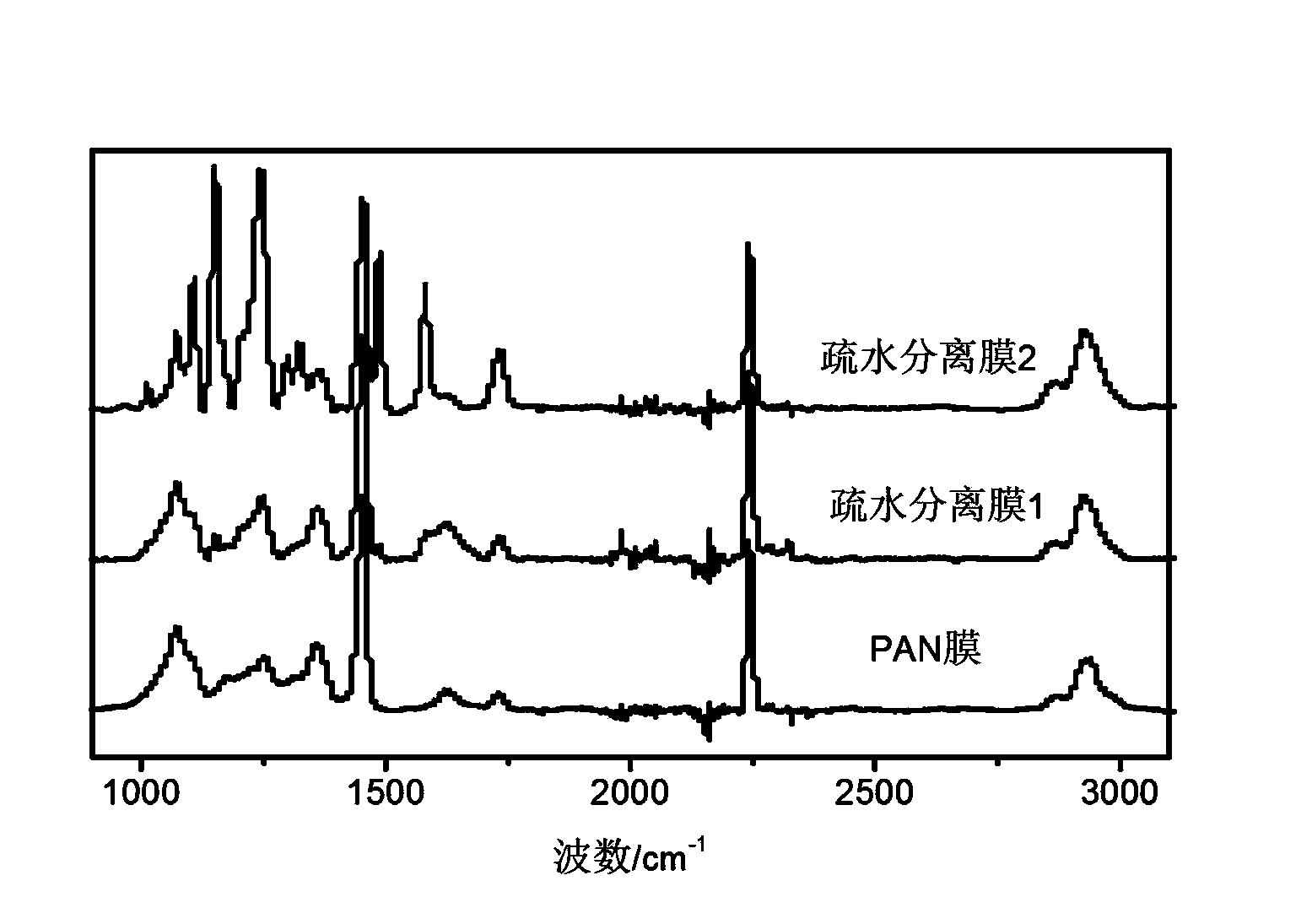

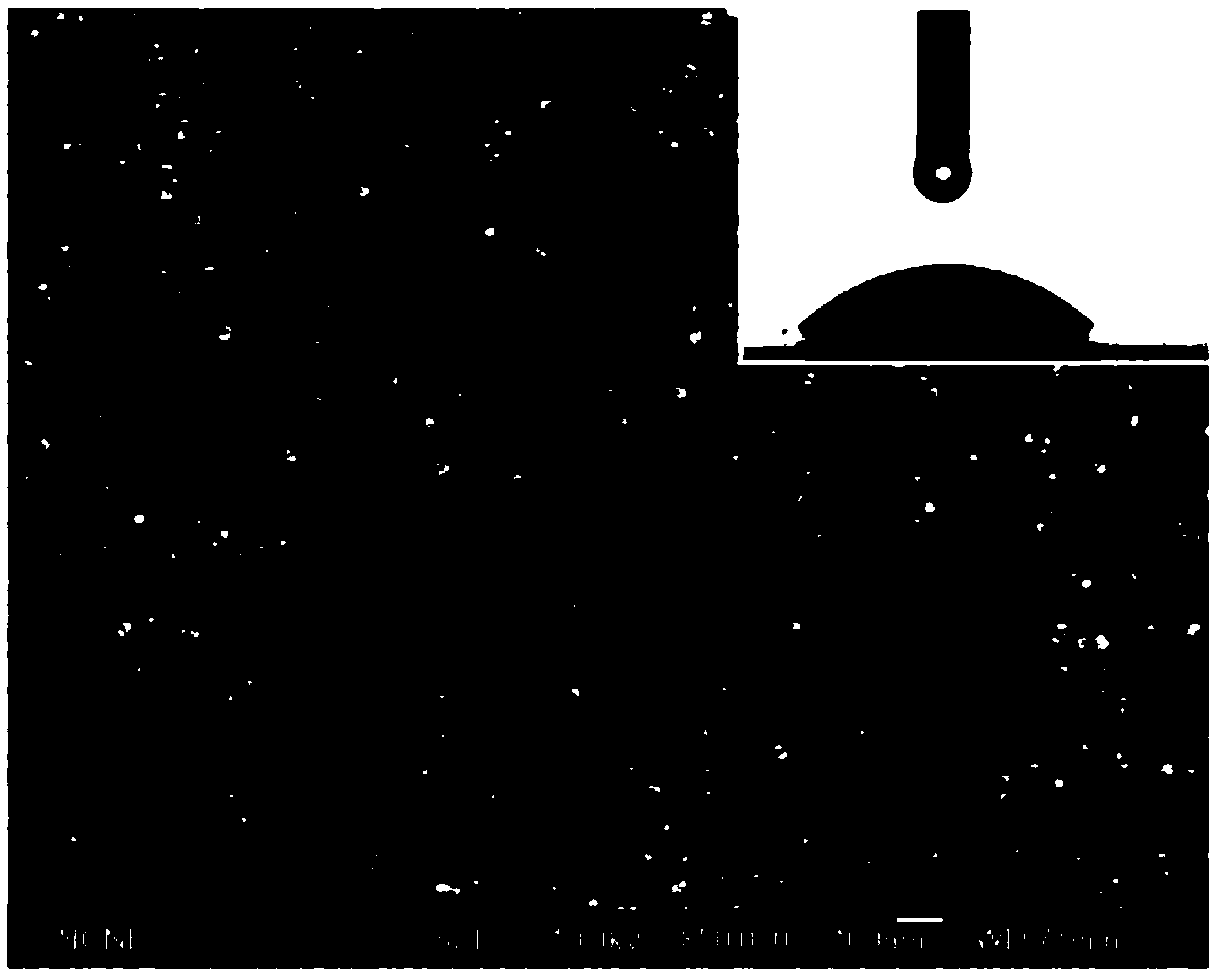

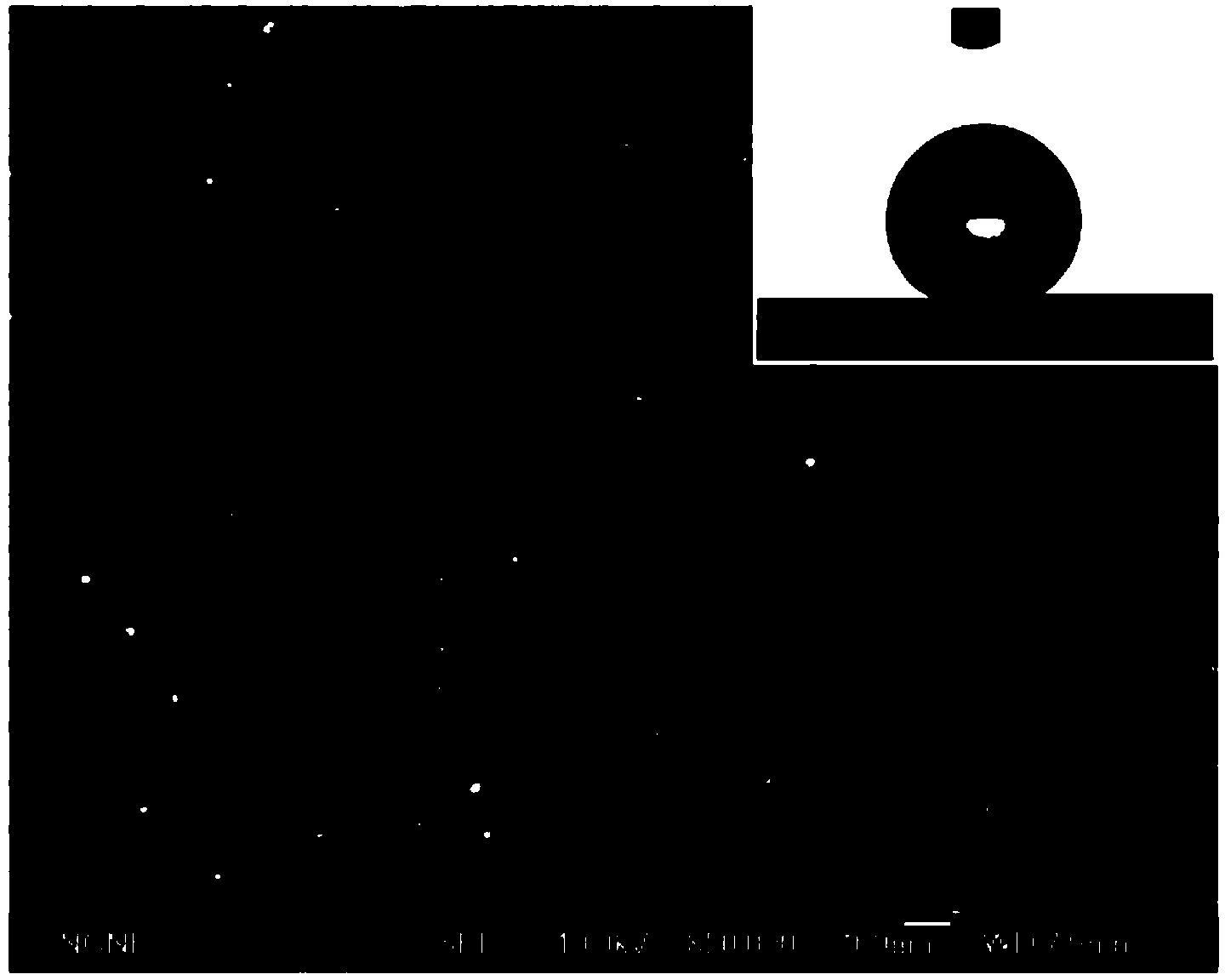

[0034] figure 1 It is the infrared spectrogram of the PAN base membrane and the prepared hydrophobic separation membrane 1 and 2 in the above-mentioned examples 1 and 2. The results showed that, compared with the PAN membrane, the hydrophobic separation membranes 1 and 2 were separated at 1740cm -1 There is an obvious ester group characteristic peak at the place, which proves that there is graft polymer B on the surface of the membrane after spraying; the hydrophobi...

Embodiment 3

[0039] This example is a blank example. The PAN base film used in Examples 1 and 2 was treated with plasma Ar according to the method described in Example 1, the irradiation power was 100W, and the irradiation time was 3min to obtain a modified film 3, whose pure water contact angle was 22°, and water penetration The pressure is lower and cannot be used in the membrane distillation desalination process. The positive effects of spray modification in Examples 1 and 2 are proved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pure water contact angle | aaaaa | aaaaa |

| Pure water contact angle | aaaaa | aaaaa |

| Upstream pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com