Method for producing modified conjugated diene rubber

一种共轭二烯、橡胶的技术,应用在橡胶交联物,橡胶交联物的改性共轭二烯类橡胶领域,能够解决低发热性、耐磨损性差等问题,达到加工性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0125] The present invention will be further described below based on detailed examples, but the present invention is not limited to these examples. It should be noted that, hereinafter, unless otherwise specified, "%" is based on weight. In addition, tests and evaluations are as follows.

[0126] (molecular weight of rubber)

[0127] The molecular weight of the rubber was determined as a polystyrene-equivalent molecular weight by gel permeation chromatography. Specific measurement conditions are as follows.

[0128] Measuring device: high performance liquid chromatography (manufactured by Tosoh Corporation, trade name "HLC-8220")

[0129] Column: Two columns of the trade name "GMH-HR-H" manufactured by Tosoh Corporation were used in series

[0130] Detector: differential refractometer (manufactured by Tosoh Corporation, trade name "RI-8220")

[0131] Eluent: tetrahydrofuran

[0132] Column temperature: 40°C.

[0133] (branching degree of rubber)

[0134] The d...

preparation example 1

[0156] (Preparation example 1: Preparation of polymerization initiator 1 (lithiation of 1,3,5-trimethylbenzene))

[0157] Under a nitrogen atmosphere, 16 parts of cyclohexane, 0.841 parts of 1,3,5-trimethylbenzene, and 0.813 parts of tetramethylethylenediamine were added to a glass reaction vessel. Next, 1.345 parts of n-butyllithium (0.3 mol of the above-mentioned tetramethylethylenediamine per 1 mol of n-butyllithium) was added with stirring, and reacted at a reaction temperature of 60°C while stirring. On the 2nd, 18.999 parts of a solution of the polymerization initiator 1 (lithiated 1,3,5-trimethylbenzene) was obtained. Next, in order to measure the lithiation rate of the lithiated 1,3,5-trimethylbenzene obtained by the reaction, several drops of the obtained reaction liquid, reacted for 30 minutes. After extracting and washing the catalyst residue with tap water, the solvent was distilled off to obtain a yellow oily liquid.

[0158] Then, the yellow oily liquid was su...

Embodiment 1

[0166] (Preparation of Modified Styrene Butadiene Rubber 1)

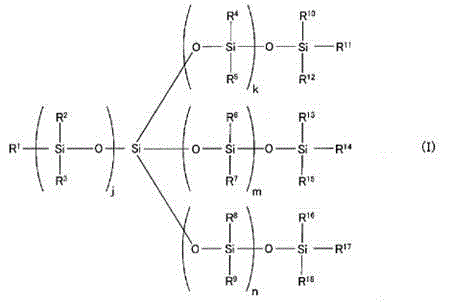

[0167] Under a nitrogen atmosphere, after putting 800 parts of cyclohexane, 94.8 parts of 1,3-butadiene, 25.2 parts of styrene and 0.232 parts of tetramethylethylenediamine into the autoclave, add 0.925 parts of The solution of the polymerization initiator 1 obtained in Preparation Example 1 (lithiated 1,3,5-trimethylbenzene) (the amount of tetramethylethylenediamine present in the reaction system is relative to every 1 mole for 1,3 , Lithiated n-butyllithium of 5-trimethylbenzene is 2.0 moles), and the polymerization starts at 60°C. The polymerization reaction was continued for 60 minutes, and after confirming that the polymerization conversion rate reached the range of 95% to 100%, 0.265 parts (1.0 mole amount relative to the Li1 mole contained in the polymerization initiator 1) of trichloride as a modifier were added. (Trimethylsilyloxy) silane (in the above general formula (5), j, k, m, n=0, R 1 = Cl, R 10 ~R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com