Method for undisturbed switching between double power sources of hydraulic station of refuse incinerator

A waste incinerator and non-disturbance switching technology, which is applied in the direction of emergency power supply arrangements, electrical components, circuit devices, etc., can solve the problems of inability to charge, inability to output continuous control power, etc., to prolong the life of capacitors, reduce weight and volume, The effect of reducing the starting inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

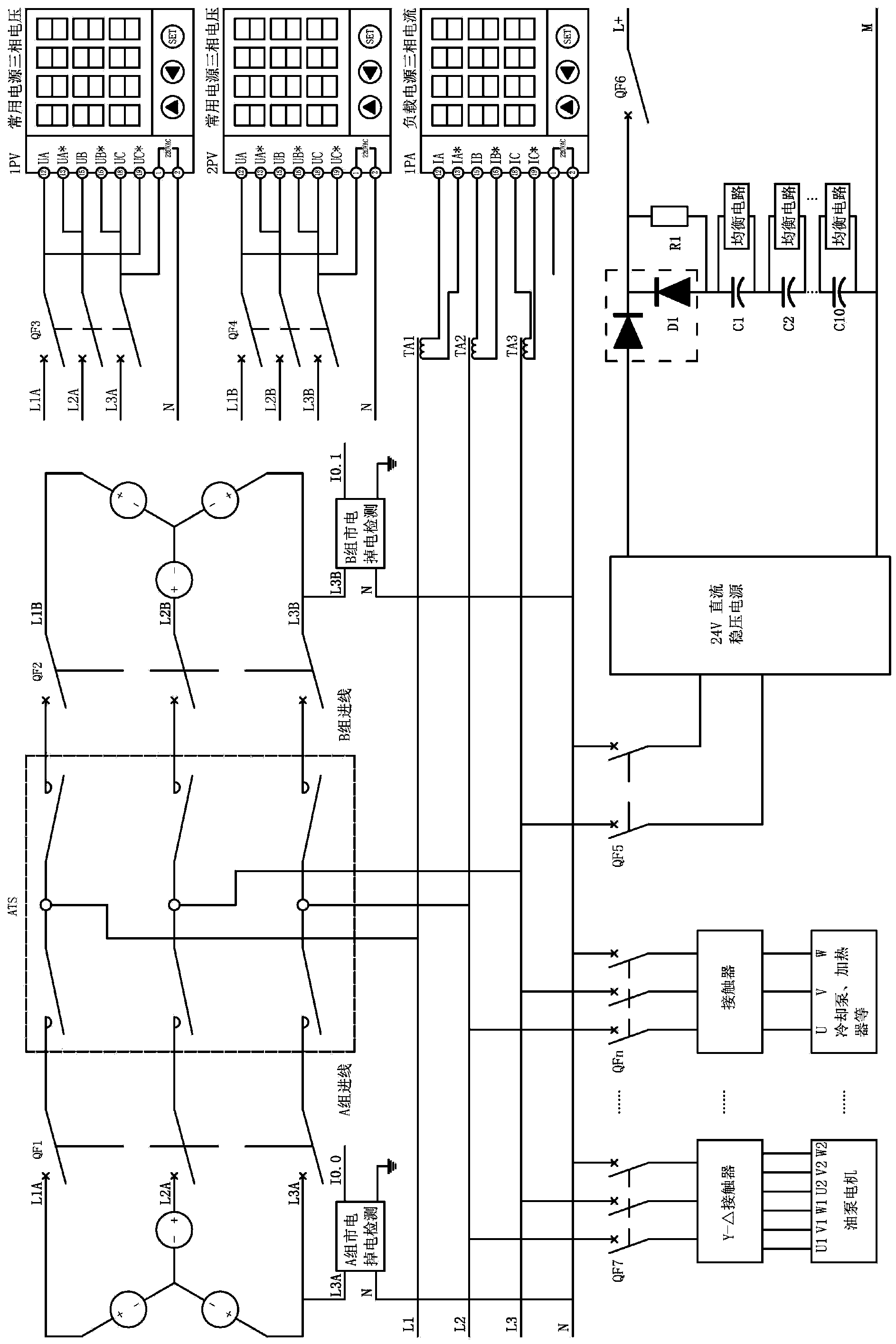

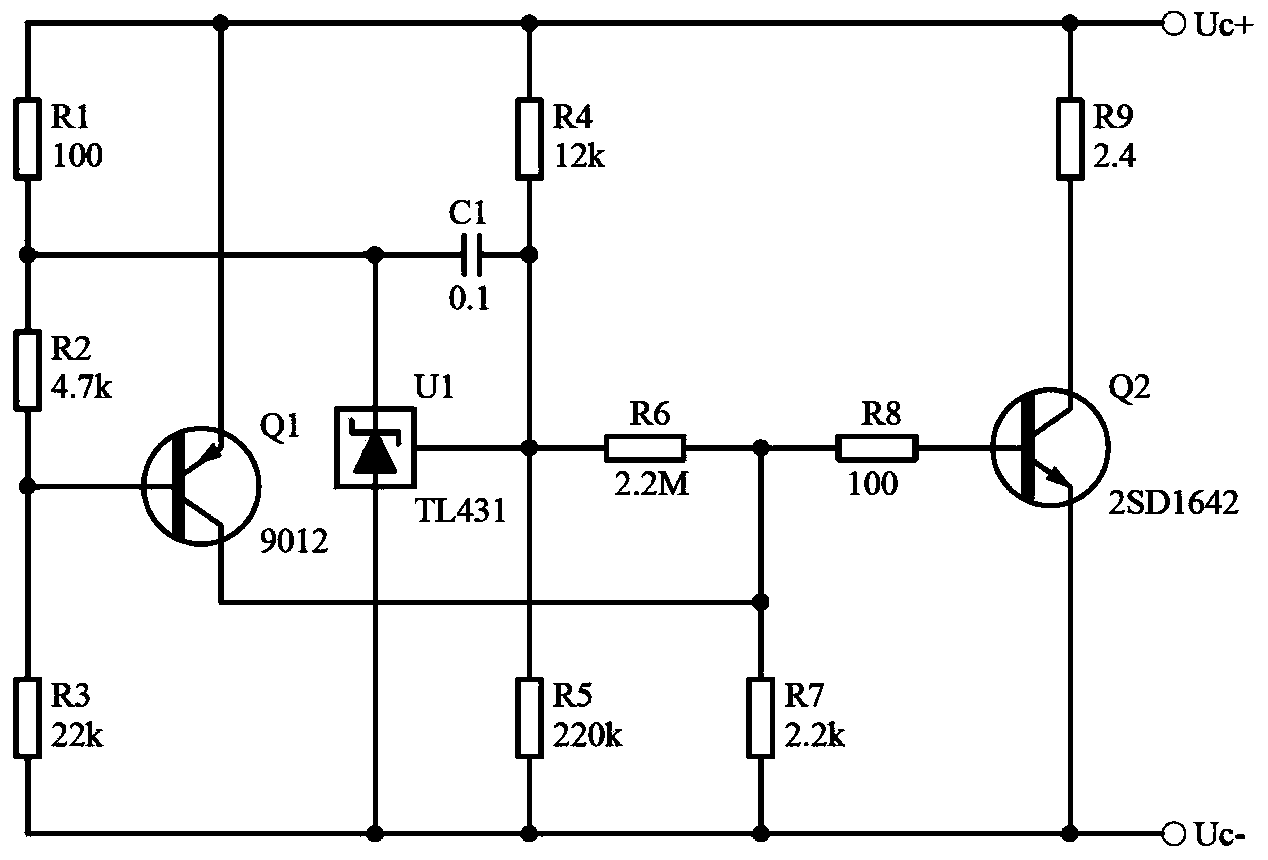

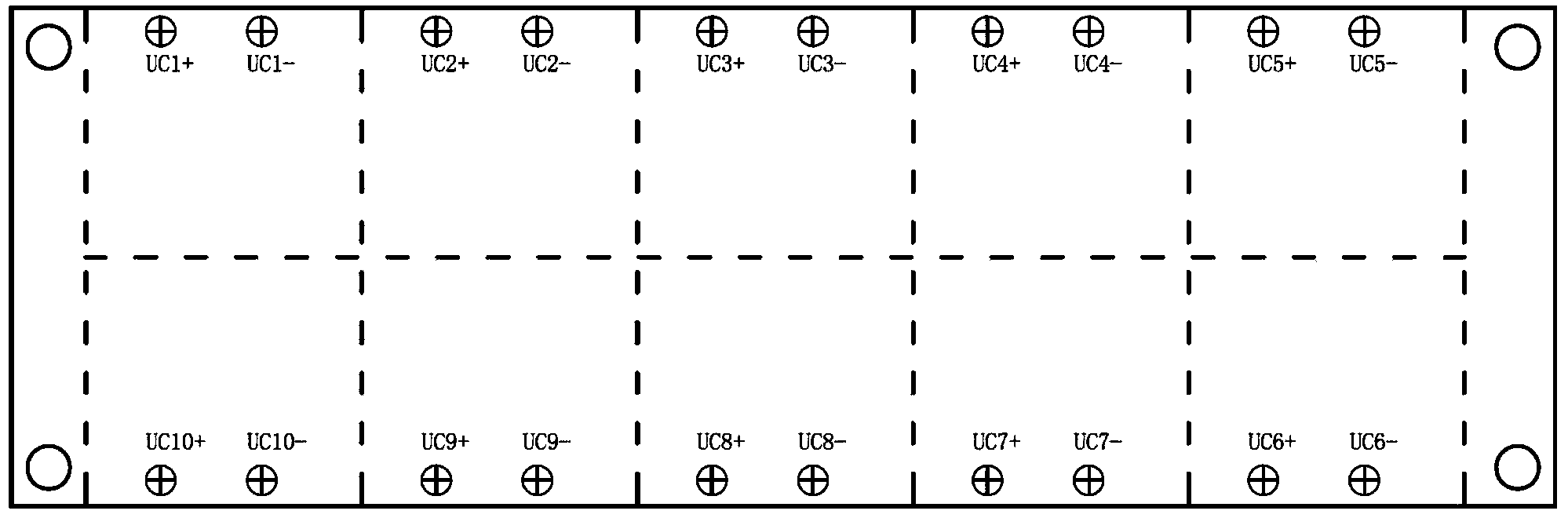

[0026] The technical scheme of the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0027] A non-disturbed switching method for dual power supplies of a hydraulic station of a garbage incinerator is characterized in that it comprises the following steps:

[0028] Step 1: Estimate the load, select the dual power switch

[0029] The main electrical equipment of the waste incineration power generation hydraulic station (oil station) includes two main oil pump motors, two cooling pumps and a heater, a DC power supply and a control system. The main oil pump motor and the cooling pump motor both work in one-use and one-backup mode. Therefore, only the power consumption of one main oil pump and one cooling pump is considered.

[0030] The total power of the power supply system is as follows:

[0031] P All = k p ( P OilPump + P CoolPump + P Heater + P DC + P ConSys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com