Testing device and method of bonding strength of thermal spraying coating on metal surface

A thermal spray coating and bonding strength technology, applied in measuring devices, mechanical devices, instruments, etc., can solve problems such as difficult bonding strength measurement, and achieve the effect of eliminating adverse effects, simple test principle and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

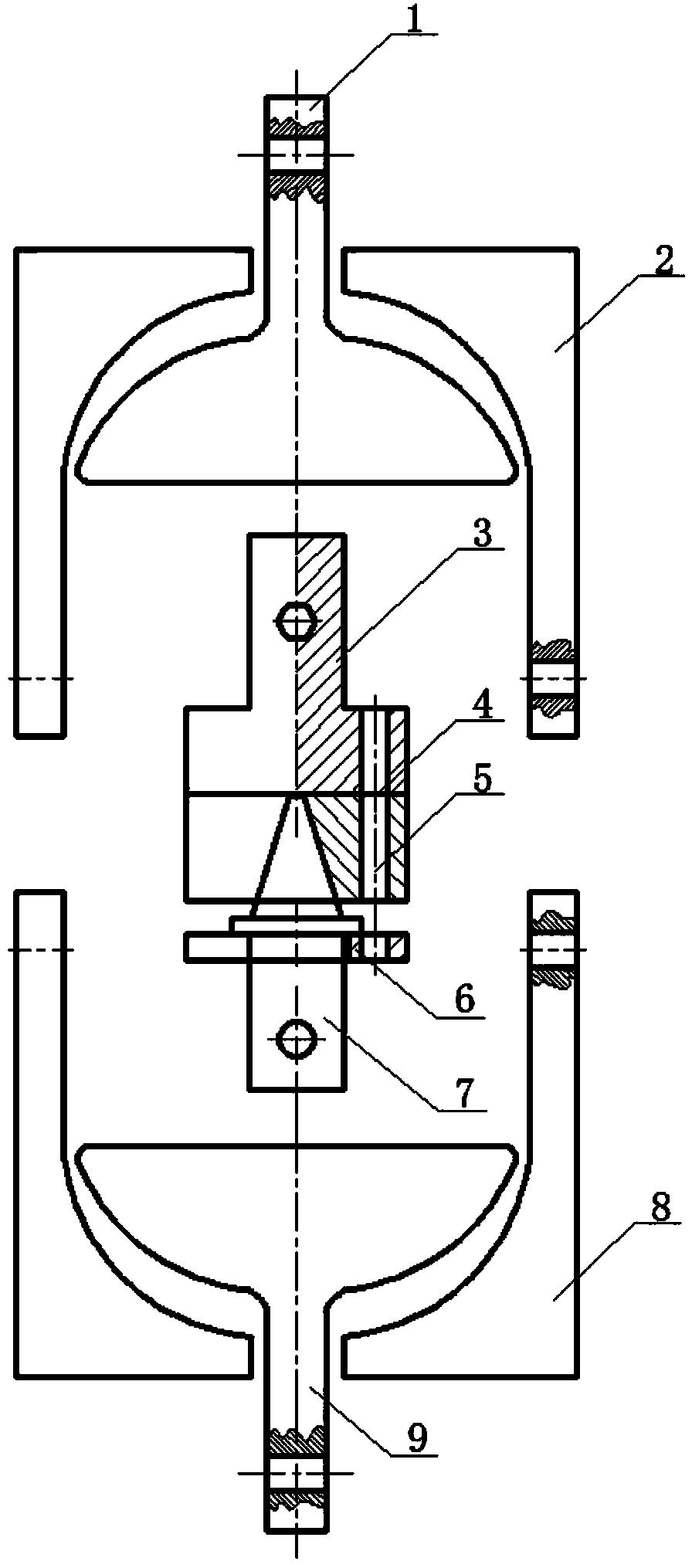

[0023] The testing process of the present invention is:

[0024] (1) Select the base material according to the test purpose to process and manufacture the base conical pin 7, insert the base conical pin 7 into the conical hole of the support block 5, and press the base conical pin 7 and the support block 5 with the pressing piece 6 and the bolt after connection;

[0025] (2) Place the above-mentioned connecting device on a lathe or a grinding machine for machining, so that the end faces of the base conical pin 7 and the support block 5 are on the same plane;

[0026] (3) After sandblasting the end face of the machined device, utilize thermal spraying equipment to prepare thermal spray coating 4 on the end faces of conical column pin 7 and support block 5. holes for protection;

[0027] (4) The pressure piece 6 of the test sample after the coating is prepared is unloaded, the position of the joint surface between the conical column pin 7 of the substrate and the coating 4 rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com