Sensor for identifying tubing coupling

A sensor and hall sensor technology, applied in the field of sensors for identifying oil pipe couplings, to achieve accurate and reliable test results, ensure stability, and strong signal anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

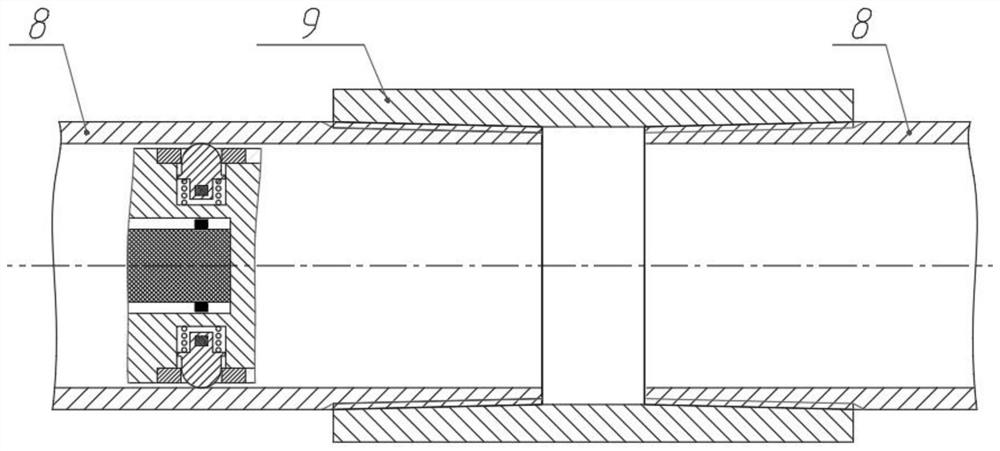

[0024] refer to Figure 1 to Figure 4 , this embodiment provides a sensor for identifying oil pipe couplings, including a mounting base 2 that is circumferentially sleeved and fixed with a limit sleeve 1, the mounting base 2 is a cylindrical structure made of non-magnetic steel, and the limit sleeve 1 is a circular ring that is tightly sleeved and fixed on the outer surface of the installation base 2. The middle part of the installation base 2 has a hole and a built-in sensor mounting seat 7. Four Hall sensors are fixed on the sensor mounting seat 7 at equal intervals along the circumferential direction. 6. The outer side of the installation base 2 is provided with four grooves 21 in one-to-one correspondence with the Hall sensor 6 along the circumferential direction, and each groove 21 is correspondingly equipped with a movable switch 3, and one end of the movable switch 3 Through the limiting sleeve 1 and extending to the outside of the limiting sleeve 1, the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com