Carbon dioxide electric welding machine connecting cable and manufacturing method thereof

A carbon dioxide, connecting cable technology, applied in the direction of cable/conductor manufacturing, insulated cable, bendable cable, etc., can solve the problem of inconvenient connection operation and use, and achieve the effect of convenient connection and use, reducing occupied space and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

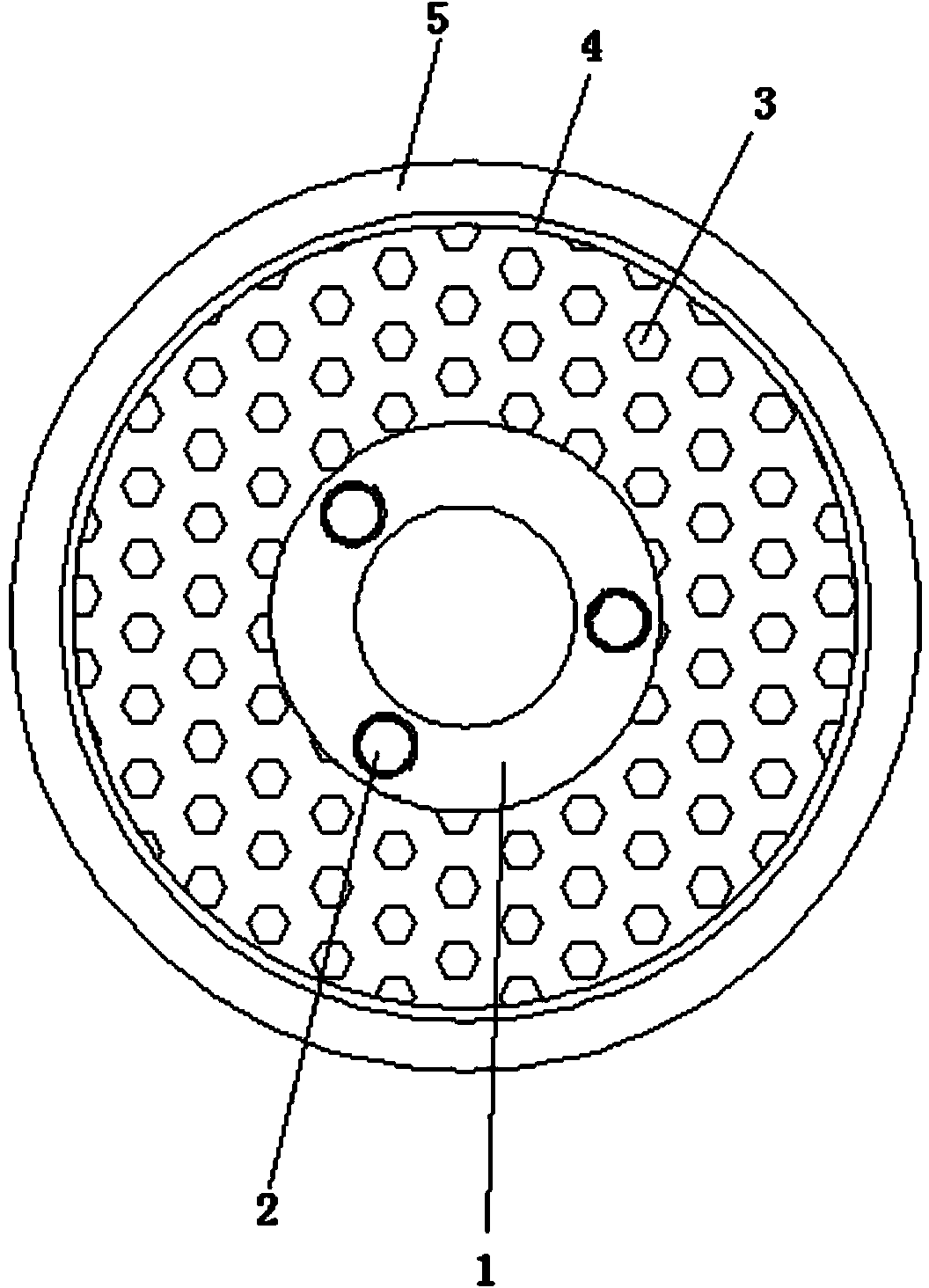

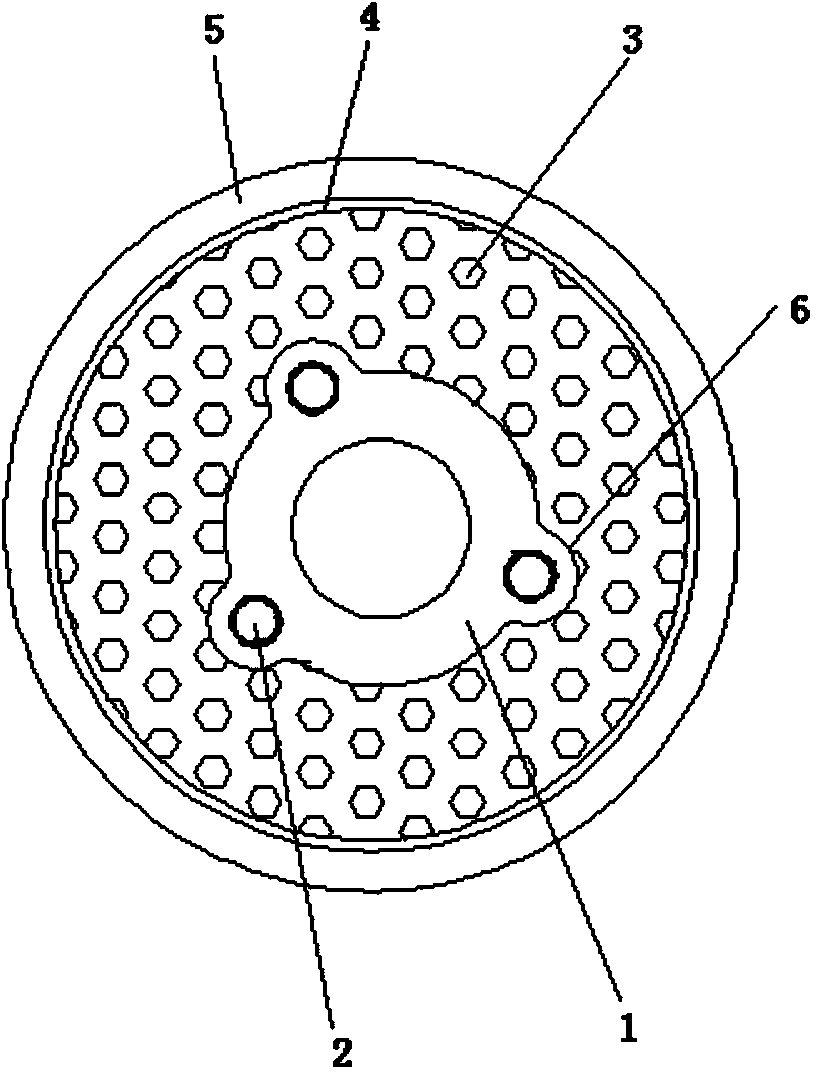

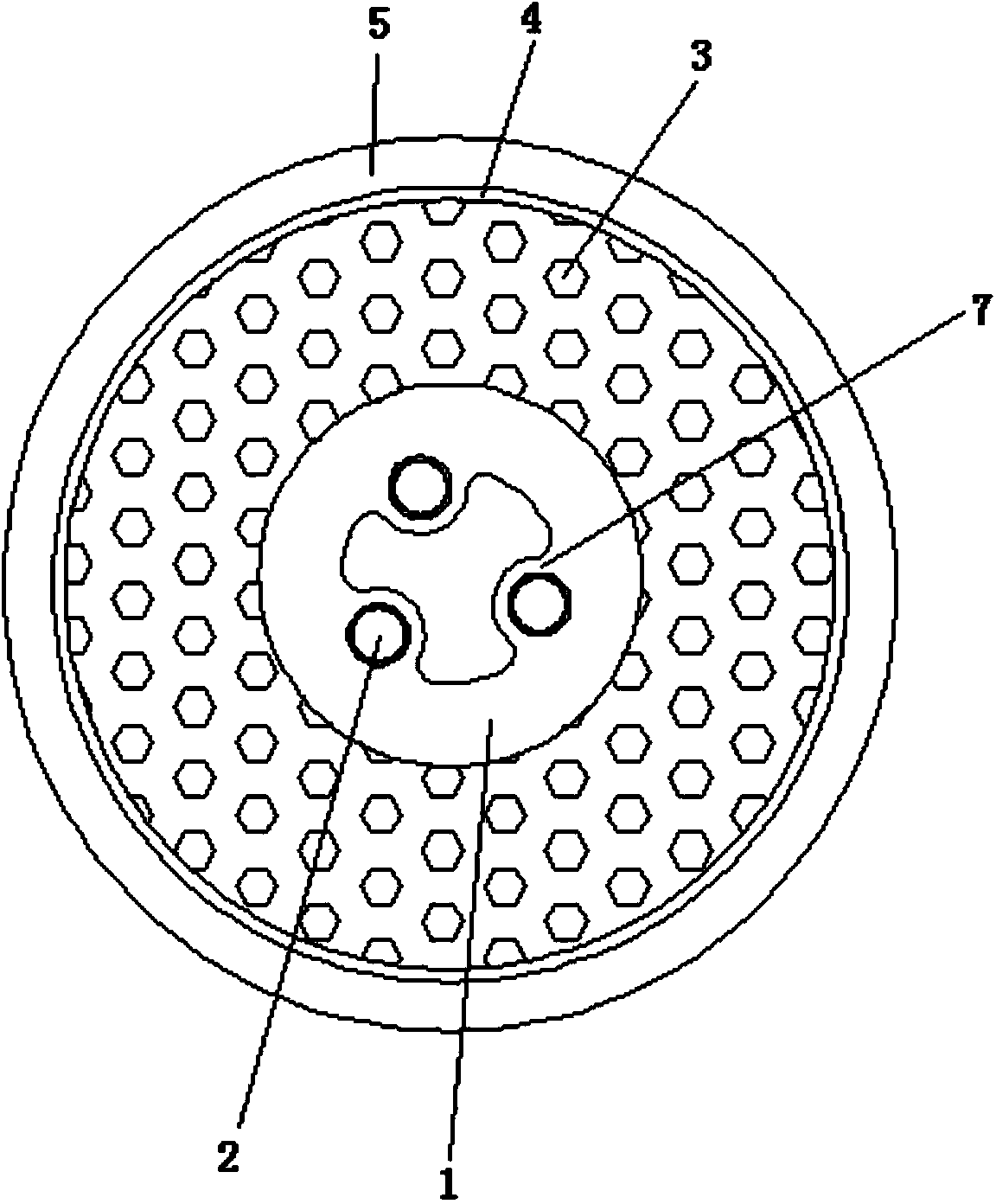

[0033] The carbon dioxide welding machine connection cable of the present invention comprises a carbon dioxide gas supply pipe 1, a control signal line 2, a copper wire conductor strand 3, a flame-retardant layer 4 and an insulating layer 5; the copper wire conductor strand 3 is wrapped outside the carbon dioxide gas supply pipe 1; The combustion layer 4 is wrapped outside the copper wire conductor strand 3; the insulating layer 5 is wrapped outside the flame-retardant layer 4; the control signal line 2 is set in the space between the inner wall of the carbon dioxide gas supply pipe 1 and the outer wall of the insulating layer 5, that is, the control signal The wire 2 can be arranged in the pipe wall of the carbon dioxide gas supply pipe 1 , in the copper wire conductor strand 3 , in the flame retardant layer 4 or in the insulating layer 5 .

[0034] figure 1 It is a schematic cross-sectional view of the first embodiment of the carbon dioxide welding machine connection cable o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com