Molten salt reactor waste heat cooling device and method thereof

A waste heat cooling and molten salt reactor technology, which is applied to cooling devices, reactors, and greenhouse gas reduction, can solve problems such as low heat exchange efficiency, achieve cost reduction, improve heat exchange efficiency, and reduce occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

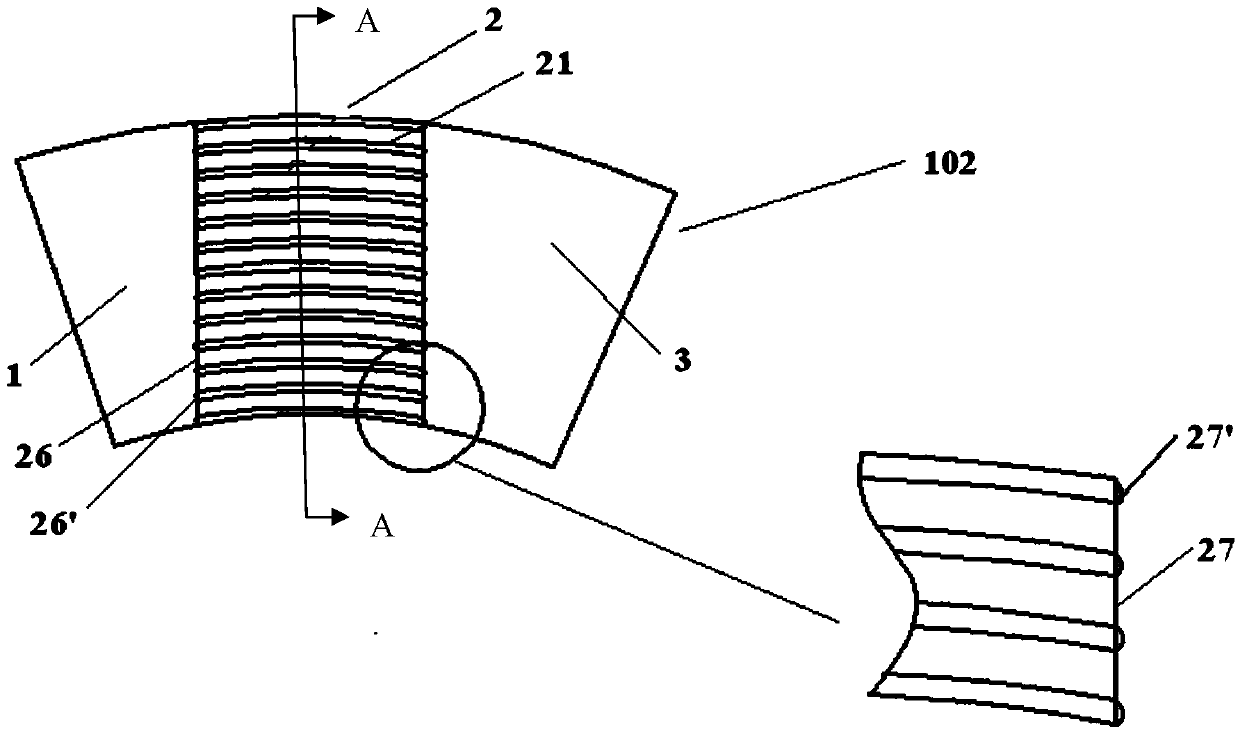

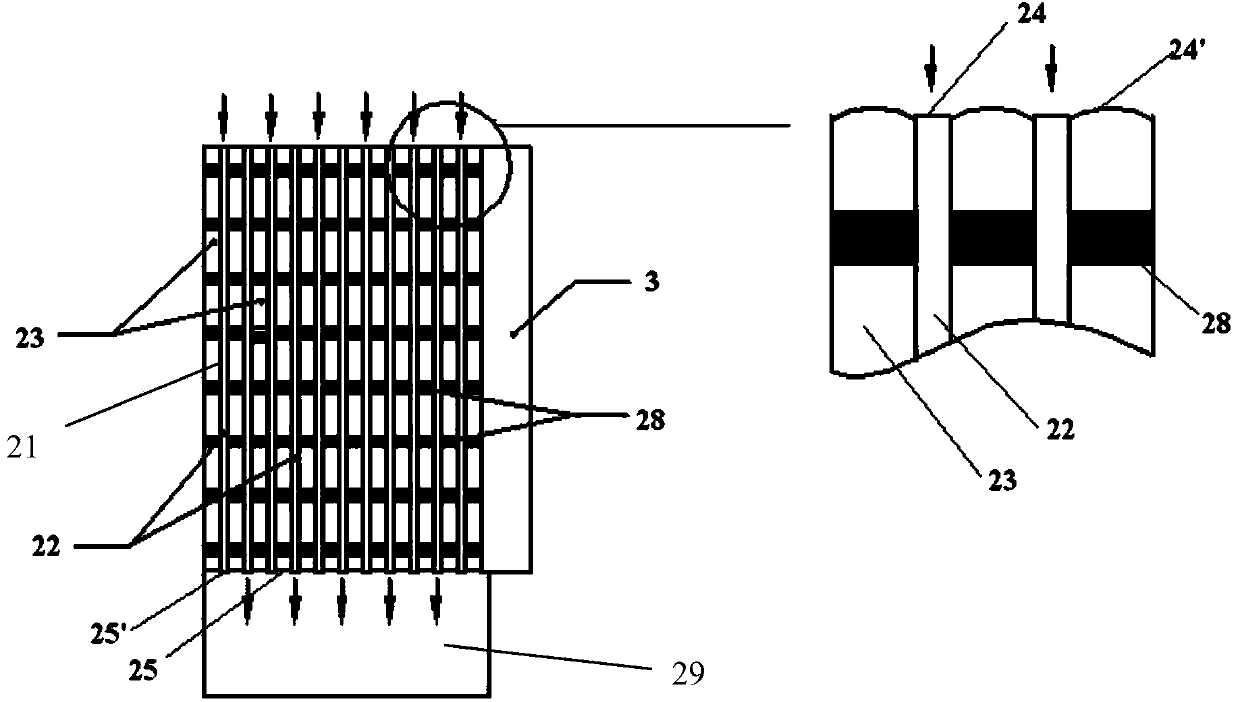

[0028] According to an embodiment of the present invention, a molten salt reactor waste heat cooling device mainly includes a plate air cooler, such as Figure 1-2 As shown, the plate air cooler 102 includes an air cooler core 2, an air inlet section 1 and an air outlet section 3, and a guide groove 29. The top plan view of the plate air cooler has a circular cross-sectional shape, the air inlet section 1 and the air The outlet sections 3 are respectively located at opposite ends of the air cooler core 2 in the horizontal direction, namely figure 1 The left and right ends of the . The air cooler core 2 includes a plurality of heat transfer plates 21 extending parallel to each other in the vertical direction, and the heat transfer plates 21 connect the air inlet section 1 and the air outlet section 3 through; wherein, the heat transfer plates 21 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com