An electrospinning device for preparing nanofiber bundles

A nanofiber and electrospinning technology, which is applied in fiber processing, textiles and papermaking, and filament/thread forming, etc., can solve the problems of complex device structure, low fiber orientation, and poor mechanical properties, and achieve simple device structure, The effect of good mechanical properties and convenient quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

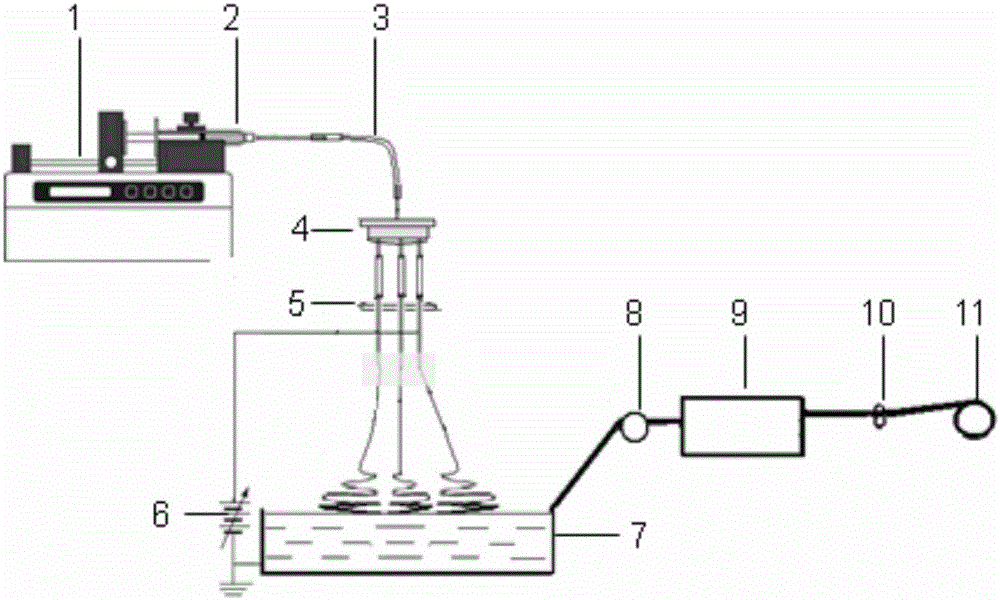

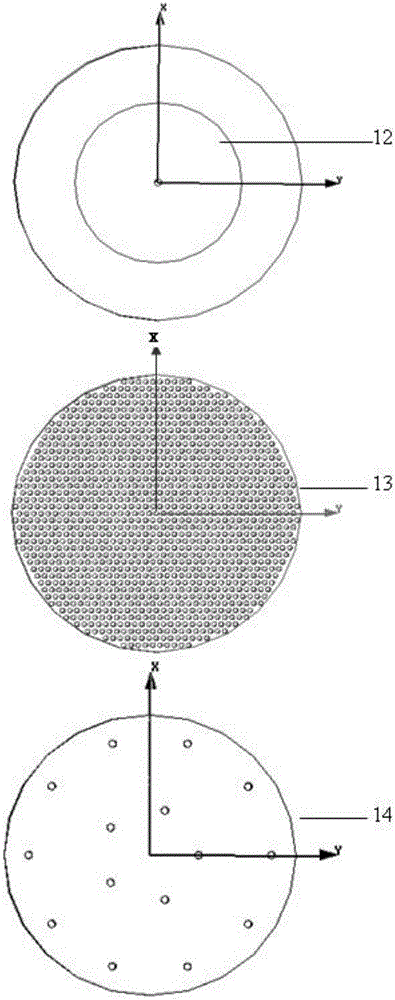

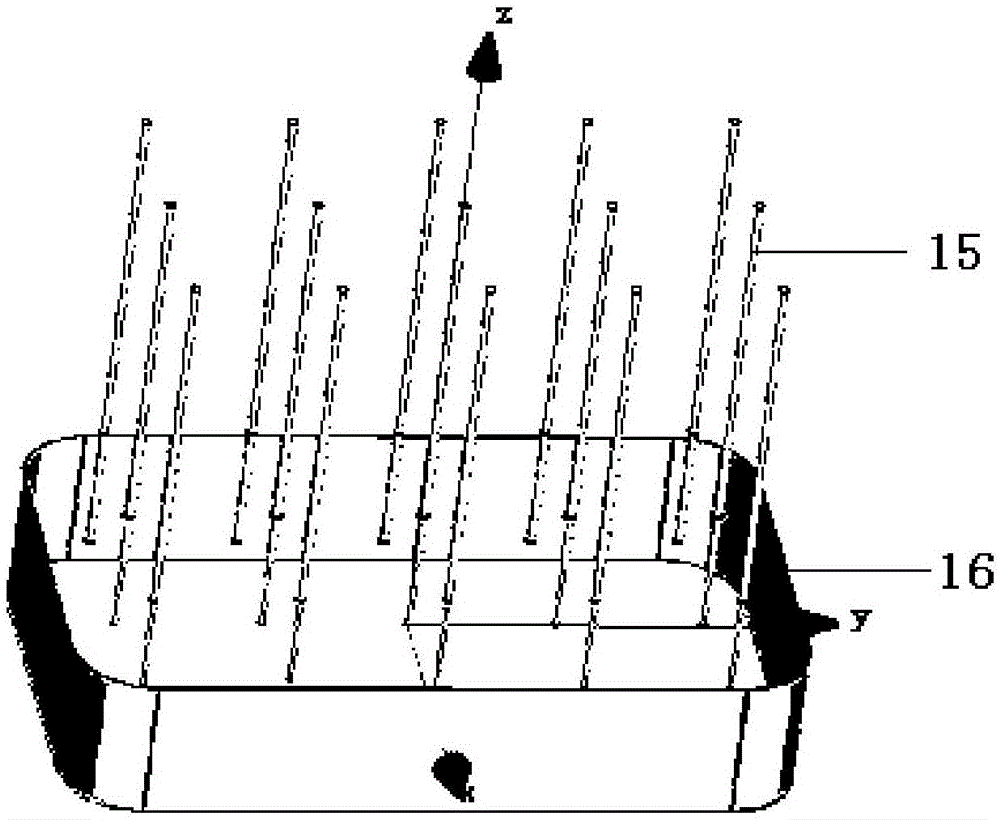

[0030] like Figure 1 to Figure 5 As shown, an electrospinning device for preparing nanofiber bundles provided in this embodiment includes a flow pump 1, a glass syringe 2 placed on the flow pump 1, and a polyamide connected to the output end of the glass syringe 2 and the input end of the distributor 4. The vinyl fluoride tube 3 constitutes the spinning solution delivery device. The distributor 4 is a multi-stage distributor, which is composed of a liquid storage tank 12 , a primary porous plate 13 and a secondary porous plate 14 in sequence. like figure 2 shown. The output end of the distributor 4 is connected to a spinneret 5 . The spinneret 15 is distributed on the spinneret 5, and the auxiliary electrode 16 is fixed on the spinnerette 5 by an insulating material, such as image 3 The arrangement of the auxiliary electrode 16 and the position of the spinneret 15 is shown. The axis of the center plane of the auxiliary electrode 16 coincides with the axis of the spinn...

Embodiment 2

[0037] The preparation of spinning solution and bath liquid of this embodiment is the same as that of Example 1.

[0038] Wherein spinning plate 5 is changed into 15 spinnerets, as image 3 Shown is the arrangement of 15 spinnerets; the voltage of the high-voltage power supply 6 is 26kV, and the flow rate of each spinneret is 0.1mL / h; the size of the auxiliary electrode is 60mm×40mm, and other parameters and nanofiber preparation methods are the same as in Example 1.

[0039] The structure and mechanical properties of the nanofiber bundles prepared in this example are shown in Table 3. The degree of orientation of the spun nanofiber bundle is about 22% higher than that of the 15 spinneret without auxiliary electrodes. The diameter of nanofiber bundles spun by 15 spinnerets is about 12 times the diameter of nanofiber bundles spun by single spinnerets at the same winding speed.

[0040] Table 315 Structure and mechanical properties of spinneret electrospun polyamide 6 nanofiber ...

Embodiment 3-5

[0043] The preparation of spinning solution and bath solution of this embodiment is the same as that of Example 2.

[0044] Among them, the heights of the 15 spinneret auxiliary electrodes 16 copper sheets were respectively changed to 15mm, 17.5mm, and 22.5mm, and other technical parameters of the device and the preparation method of nanofibers were the same as in Example 2. The orientation degrees of the prepared three nanofiber bundles are shown in Table 4.

[0045] Table 4 Orientation degree of polyamide 6 nanofiber bundles spun with different sheet height auxiliary electrodes

[0046]

[0047] It can be concluded from the above Table 4 that the auxiliary electrodes 16 with different sheet heights have different improvement effects on the multi-nozzle electric field, resulting in different orientation degrees of the spun nanofiber bundles, but the orientation degree of the spun nanofiber bundles after using the auxiliary electrodes 16 is different. Both are larger than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com