A kind of heat-conducting graphite composite material and preparation method thereof

A composite material and heat-conducting graphite technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems affecting the orientation degree of flake graphite grains, complex process, uneven thickness, etc., and achieve high thermal conductivity and simple process , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a kind of preparation method of heat-conducting graphite composite material, it comprises the following steps:

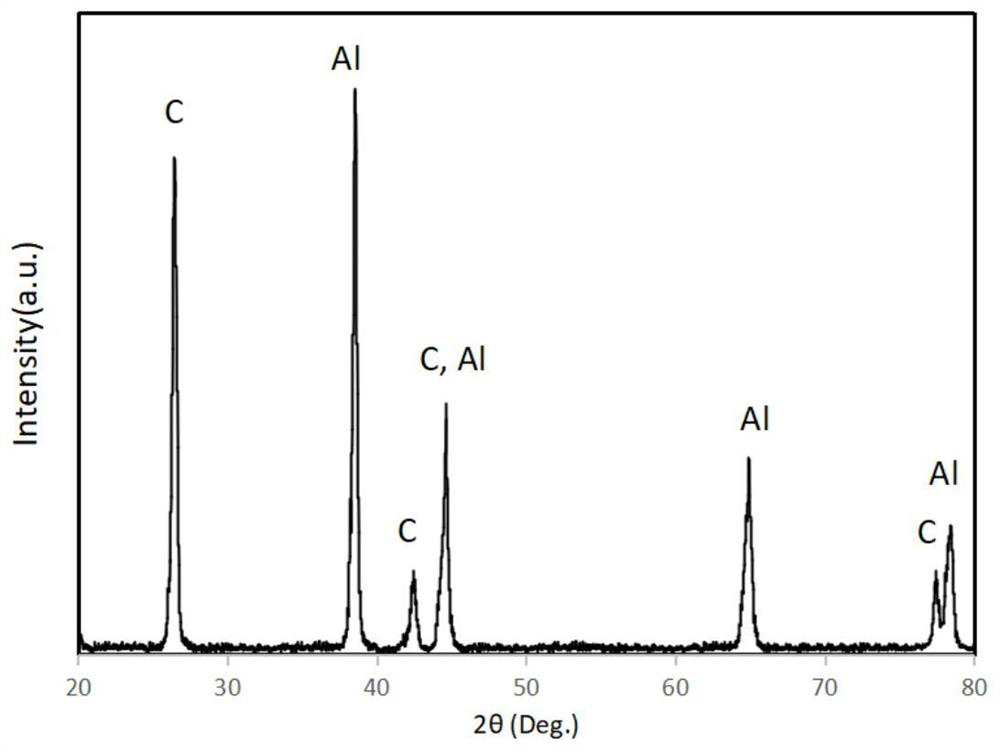

[0027] S1. Use flake graphite as the orientation element, aluminum powder as the matrix, and silicon powder as the interface wetting agent; mix 300g of flake graphite and 700g of aluminum powder, and then mix with 8g of the interface wetting agent to obtain a mixed powder Among them, flake graphite can pass through a 100-mesh sieve, that is, the particle size can be controlled between 20 and 150 microns, and the distribution is wide, which is conducive to increasing the density of the oriented layer.

[0028] S2, using ethyl cellulose as a binding agent, terpineol as a solvent; 10g of binding agent and 180g of solvent are heated and stirred to form a transparent solution, then mixed with 120g of the above-mentioned mixed powder, and ball milled, Get a slurry.

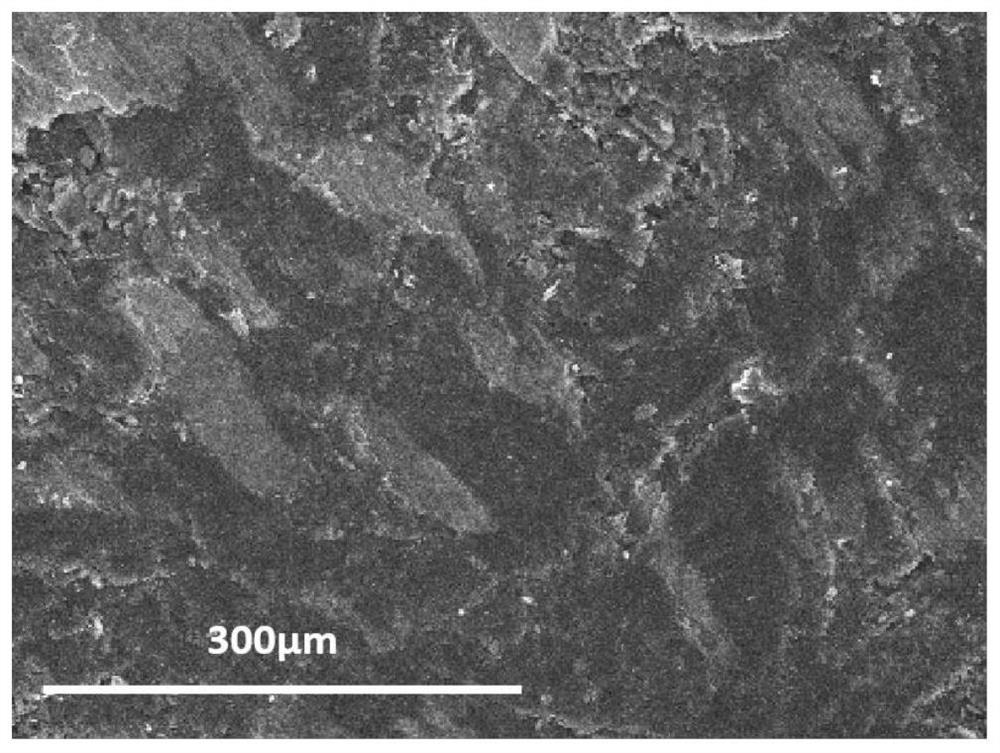

[0029] S3. After the above slurry is printed on the substrate by screen p...

Embodiment 2

[0033] This embodiment provides a kind of preparation method of heat-conducting graphite composite material, it comprises the following steps:

[0034] S1. Use flake graphite as the orientation unit, aluminum powder as the matrix, and silicon powder as the interface wetting agent; mix 200 flake graphite and 800g aluminum powder, and then mix with 5g of the interface wetting agent to obtain a mixed powder .

[0035] S2, with the equal mass ratio mixture of ethyl cellulose, methyl cellulose and nitrocellulose as binder, the equal volume ratio mixture of terpineol and ethylene glycol as solvent; 10g binder and 150g solvent are heated After stirring and mixing to form a transparent solution, it was mixed with 100 g of the above mixed powder to obtain a slurry.

[0036] S3. After the above slurry is printed on the substrate by screen printing, it is then placed in an oven at 90°C for drying treatment, and this step is repeated several times to obtain a thick film with a thickness ...

Embodiment 3

[0040] This embodiment provides a kind of preparation method of heat-conducting graphite composite material, it comprises the following steps:

[0041] S1. Use flake graphite as the orientation unit, aluminum powder as the matrix, and silicon powder as the interface wetting agent; mix 400g of flake graphite and 600g of aluminum powder, and then mix with 10g of the interface wetting agent to obtain a mixed powder Among them, flake graphite can pass through a 100-mesh sieve, that is, the particle size can be controlled between 20 and 150 microns, and the distribution is wide, which is conducive to increasing the density of the oriented layer.

[0042] S2, using the equal mass ratio mixture of methyl cellulose and nitrocellulose as the binder, and the equal volume ratio mixture of ethylene glycol as the solvent; after heating and stirring 10g of the binder and 200g of the solvent to form a transparent solution, then Mix with 150 g of the above mixed powder, and perform ball milli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal properties | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com