Special coating for acrylic finishes, and making method thereof

An acrylic topcoat and coating technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of slow natural drying, large environmental pollution, large VOC emissions, etc., and achieve fast drying and good anti-corrosion performance. , good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

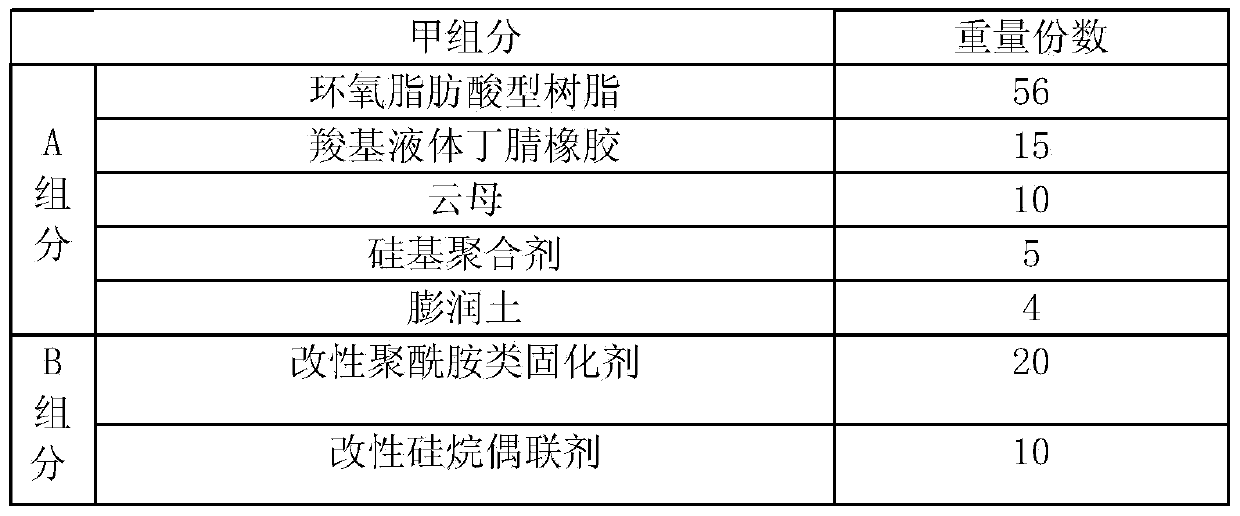

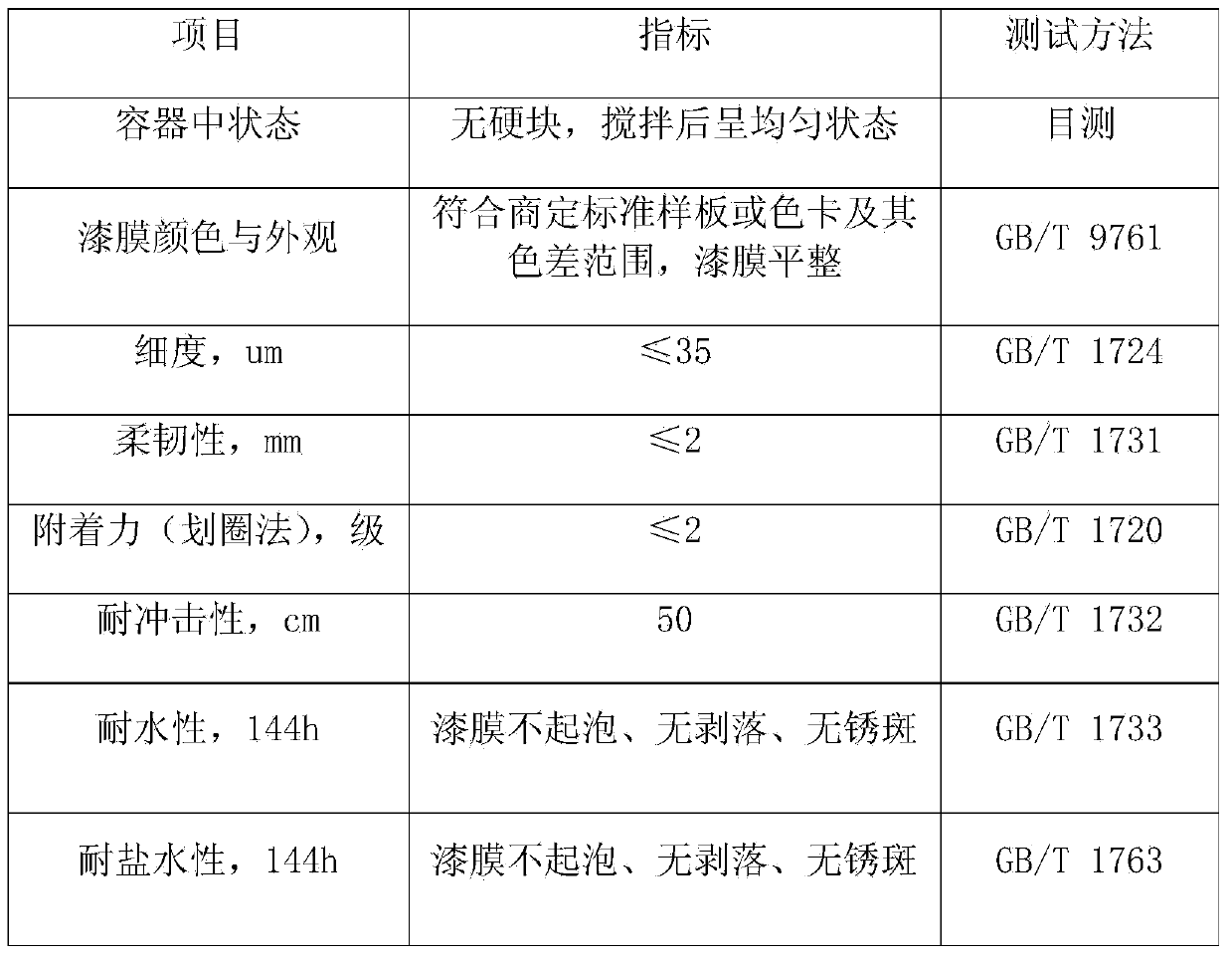

[0042] This embodiment provides a special coating for acrylic topcoats, including two components, A and B, and A and B are two components consisting of A and B components. A and B include the following components in parts by mass, as shown in Table 1 and 2 as shown:

[0043] Table 1 is the components that A contains in parts by mass

[0044]

[0045] Table 2 is the components that B contains in parts by mass

[0046] B component

parts by weight

Polyurethane Modified Acrylic Resin

70

23

Texanol

3

Dipropylene glycol butyl ether (DPnB)

3

pure water

20

0.2

Hydrophobic modified carboxylic acid sodium salt

0.3

polyethylene glycol dioleate

0.1

0.1

diatomaceous earth

0.3

[0047] The preparation method of the special coating comprises the following steps;

[0048] (1) Preparation of A compone...

Embodiment 2

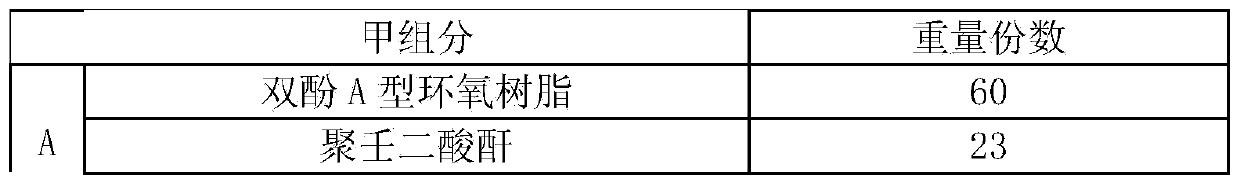

[0064] This embodiment provides a special coating for acrylic topcoat, including two components, A and B, and A and B are two components consisting of A and B components. A and B include the following components in parts by mass, as shown in Table 4 and 5 as shown:

[0065] Table 4 is the components that A contains in parts by mass

[0066]

[0067]

[0068] Table 5 is the components that B contains in parts by mass

[0069] B component

parts by weight

Polyurethane Modified Acrylic Resin

69

24.5

Texanol

7.5

Dipropylene glycol butyl ether (DPnB)

7.5

pure water

20

0.2

Hydrophobic modified carboxylic acid sodium salt

0.35

polyethylene glycol dioleate

0.35

0.1

diatomaceous earth

0.5

[0070] The preparation method of the special coating comprises the following steps;

[0071] (1) Prepa...

Embodiment 3

[0088] This embodiment provides a special coating for acrylic topcoat, including two components, A and B, and A and B are two components consisting of components A and B. A and B include the following components in parts by mass, as shown in Table 7 and 8 as shown:

[0089] Table 7 is the components that A contains in parts by mass

[0090]

[0091] Table 8 is the components that B contains in parts by mass

[0092] B component

parts by weight

Polyurethane Modified Acrylic Resin

67

25

Texanol

7.5

Dipropylene glycol butyl ether (DPnB)

7.5

pure water

20

0.1

Hydrophobic modified carboxylic acid sodium salt

0.2

[0093] polyethylene glycol dioleate

0.2

0.1

diatomaceous earth

0.4

[0094] The preparation method of the special coating comprises the following steps;

[0095] (1) Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com