Application of Iron Oxides in Eliminating Irritating Odor in Red Phosphorus Flame Retardant Nylon

A pungent odor and iron oxide technology, applied in the field of material processing, can solve problems affecting the physical and mental health of production personnel and users, poor air quality, and odor of red phosphorus flame-retardant nylon materials, etc., to meet the requirements of environmental protection and health Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 prepares active iron oxide

[0020] Weigh ferric nitrate and dissolve it in deionized water to make a 0.2mol / L aqueous solution; then drop ammonia water until the pH value reaches above 10, and let it stand for precipitation; filter and dry the filter cake at 60°C; In the SG-XL1200 box-type muffle furnace, calcinate at 400°C for 4 hours to obtain active iron oxide, take it out and grind it and pass it through a 320 mesh sieve to obtain active iron oxide mixed with ferric oxide and ferric oxide .

[0021] Active Iron Oxide No.

[0022] 4#

Embodiment 2

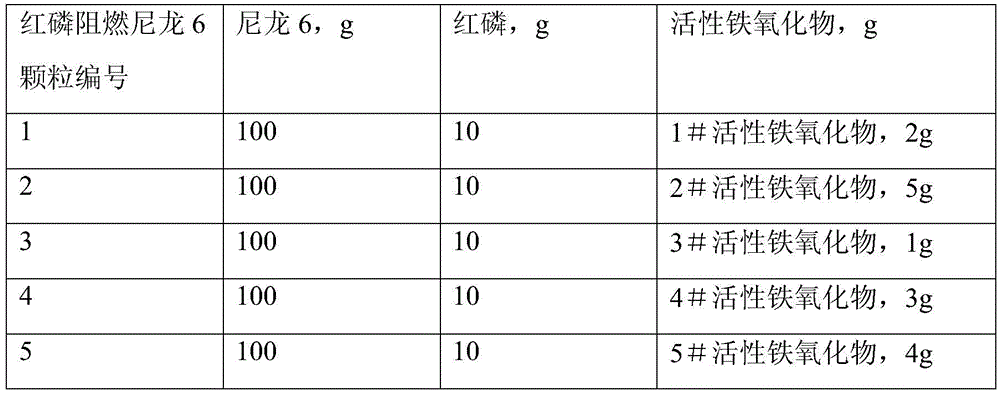

[0023] Preparation of embodiment 2 red phosphorus flame-retardant nylon

[0024] Take the above-prepared active iron oxide, nylon 6 and red phosphorus, and melt and mix them uniformly in the Jieant SHJ-20 extruder. The extrusion temperatures of each section are: 240°C in zone 1, 240°C in zone 2, and 240°C in zone 3 240°C, 240°C in zone 4, 245°C in zone 5, 245°C in zone 6, 245°C in zone 7, the screw speed is 20 rpm, and the red phosphorus flame retardant containing active iron oxide deodorant is obtained by extrusion and granulation Nylon 6 pellets.

[0025]

Embodiment 3

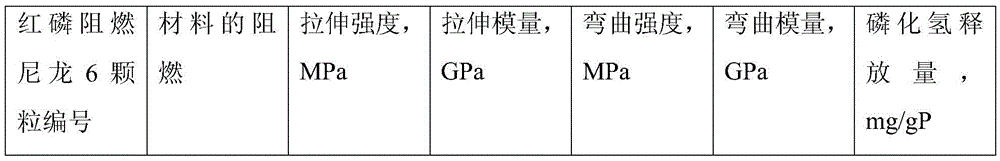

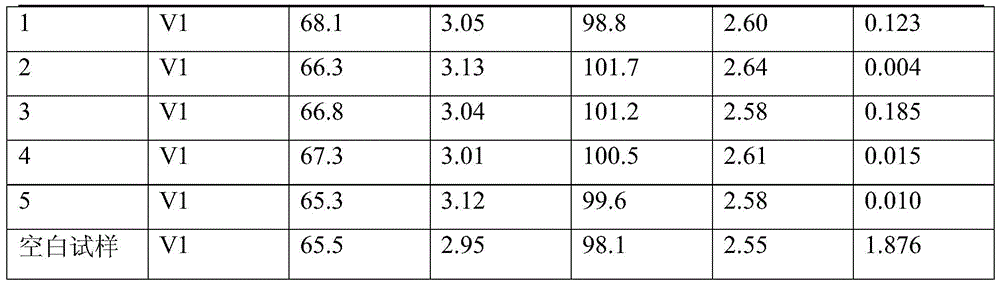

[0026] Embodiment 3 performance test

[0027] Use Haitian MA600.150 injection molding machine to obtain mechanical properties and flame retardant test specimens. The temperature of each section of the injection molding machine is set to: 245°C in zone 1, 245°C in zone 2, 245°C in zone 3, and 250°C in zone 4. Tensile test The standard is ISO527, the bending test standard is ISO178, and the flame retardant performance test standard is UL94.

[0028] Get 5g of the curved sample in the above-mentioned injection molding sample, heat up to 250°C and keep it warm for 1 hour, use the molybdenum blue colorimetric method to measure the amount of phosphine released (Wu Manchang et al., total phosphorus and phosphine in yellow phosphorus tail gas Determination of Environmental Pollution and Prevention, August 2004, Volume 26, No. 4), converted to the mass of phosphine gas released within 1 hour per gram of red phosphorus.

[0029] Red phosphorus flame retardant nylon 6 (blank sample) wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com