Preparation method of methyl acetylricinolate

A technology of acetyl ricinoleic acid methyl ester and ricinoleic acid methyl ester, which is applied in the field of preparation of acetyl ricinoleic acid methyl ester, can solve the unfavorable industrialized large-scale production of acetyl ricinoleic acid methyl ester, low catalytic efficiency of the catalyst, and complex process cumbersome and other problems, to achieve the effect of realizing industrialized large-scale production, improving catalytic efficiency and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

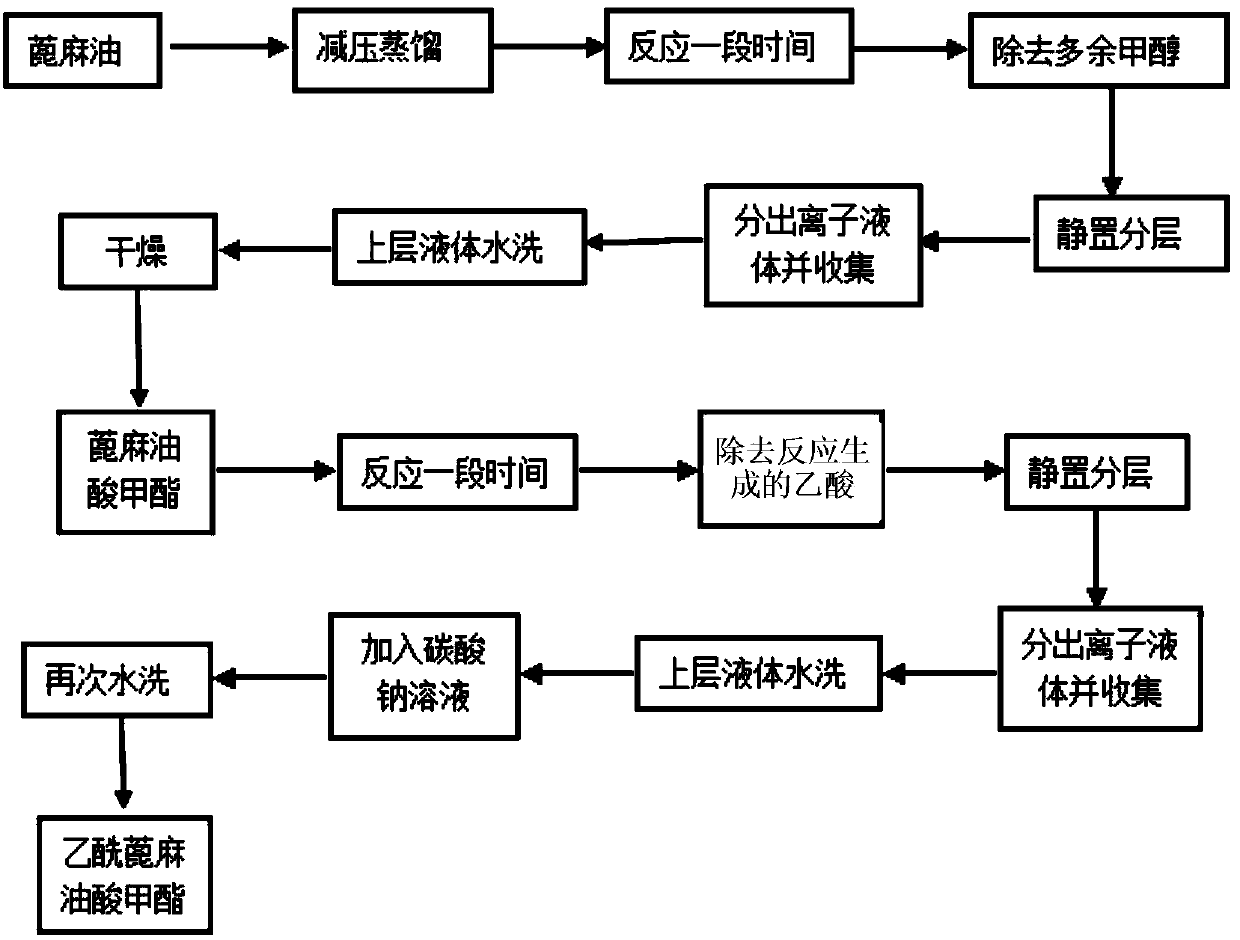

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of methyl ricinoleate

[0044] Distill 10g of castor oil under reduced pressure to remove water and other solvents in castor oil, then add the treated castor oil into a three-necked flask with a mechanical stirring device, heat to 60°C, add methanol and ionic liquid catalyst [Hmim] HSO 4 , reacted at 60°C for 2 hours, then carried out vacuum distillation, distilled off excess methanol, stood to separate layers, recycled the ionic liquid catalyst in the lower layer, took the supernatant, and washed the supernatant with water for several times , add anhydrous sodium sulfate and dry overnight, obtain methyl ricinoleate, wherein the mol ratio of methyl alcohol and castor oil is 2:1, the consumption of ionic liquid catalyst is 5% of castor oil weight, the yield of product methyl ricinoleate The rate is 61.17%.

Embodiment 2

[0045] Example 2 Preparation of methyl ricinoleate

[0046] The method of present embodiment and embodiment 1 is basically the same, and difference is that the mol ratio of methyl alcohol and castor oil is 4:1, and catalyst consumption is 10% of castor oil weight, and temperature of reaction is 70 ℃, and the reaction times is 3 hours, The yield of the product methyl ricinoleate was 79.53%.

Embodiment 3

[0047] Example 3 Preparation of methyl ricinoleate

[0048] The method of present embodiment and embodiment 1 is basically the same, and difference is that the mol ratio of methyl alcohol and castor oil is 6:1, and catalyst consumption is 10% of castor oil weight, and temperature of reaction is 75 ℃, and the reaction times is 4 hours, The yield of the product methyl ricinoleic acid was 96.67%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com