Slope belt conveyer with adjustable angle for automatic tire production line

An automated production line and belt conveyor technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems that the advantages of the automation system cannot be fully displayed, the space cannot be fully and reasonably used, and the line body is bulky, and it can be used in a wide range of applications. Simple structure and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

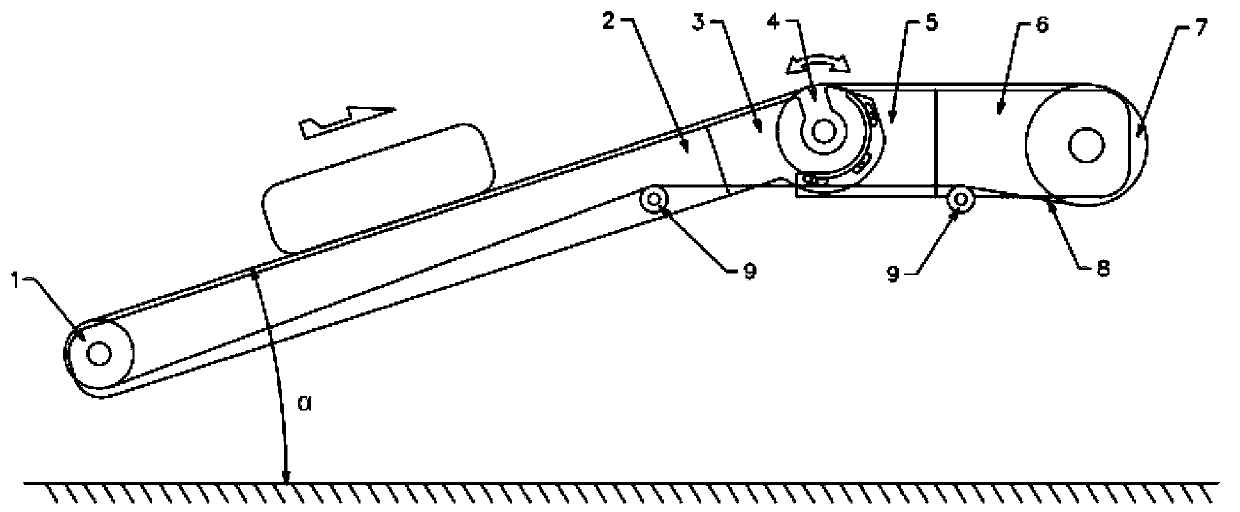

[0022] Such as figure 1 As shown, an angle-adjustable slope belt conveyor for an automatic tire production line includes a head power mechanism, an intermediate rotation mechanism, a tail drum 1, a fuselage 2 and a belt 8, and the head power mechanism, intermediate rotation Mechanism and tail drum 1 are sequentially connected by belt 8. The fuselage 2 is arranged on a slope, and the middle rotating mechanism and tail drum 1 are installed at both ends of the slope of the fuselage 2. The middle rotating mechanism drives the engine The body 2 rotates to realize the adjustable angle α between the slope of the body 2 and the ground, so as to meet the conveying directions at different heights.

[0023] The head power mechanism includes a head frame 6 and a head roller 7 fixed on the head frame 6 to provide power for the whole belt conveyor. The intermediate rotating mechanism includes a support plate 3, an intermediate drum 4 and a rotating plate 5, the intermediate drum 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com