Anti-condensation metal radiant panel and manufacturing method thereof

A radiant panel and anti-condensation technology, applied in the field of air conditioning, can solve the problems of the system cannot operate normally, the system energy consumption is high, and the windows cannot be opened for ventilation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

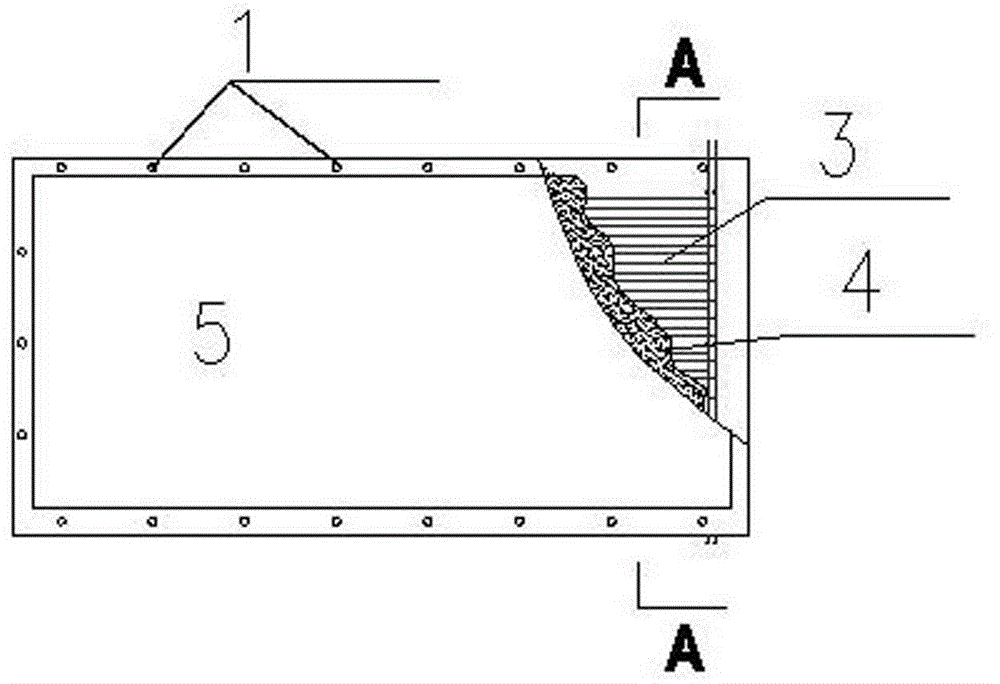

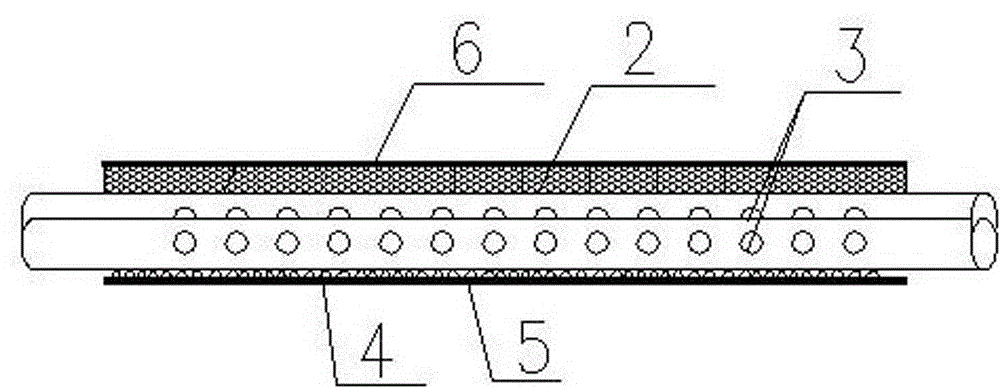

[0039] like figure 1 Shown are a top view and an A-A cross-sectional view of a super-hydrophobic metal radiant panel according to a preferred embodiment of an anti-condensation metal radiant panel and a manufacturing method thereof according to the present invention. An anti-condensation metal radiant panel includes: a super-hydrophobic metal radiant panel. Metal plate (5): It is made by super-hydrophobic surface fabrication technology, and does not condense in humid air;

[0040] Aluminum foil (4): the pipe network (3) is tightly combined with the super-hydrophobic metal plate (5) to increase the heat dissipation of the pipe network (3) and make the heat dissipation more uniform;

[0041] Pipe network (3): hot and cold water is passed through the pipe, and the heat in the water is transferred to the super-hydrophobic metal plate (5) through the aluminum foil (4);

[0042] Insulation layer (2): isolates the pipe network (3) from the top cover plate to prevent heat energy loss...

Embodiment 2

[0048] A method for making a metal radiant panel with anti-condensation. The method for making a metal radiant panel with anti-condensation includes first performing electrochemical treatment on the metal panel, and then coating a low surface energy material to obtain a metal with super-amphiphobic properties. plate. The surface of the metal plate exhibits superphobic properties for various oil droplets except fluorine-containing liquids, and the rolling angle is generally less than 10°. The surface of the metal plate can also be placed in the air for a long time and still maintain its super-amphiphobic properties, the super-amphiphobic surface of the metal plate can be stable for a long time, and still has good super-amphiphobic properties after mechanical bending and deformation. The super-amphiphobic surface of the metal plate can include molten solution droplets of super-hydrophobic paraffin and polyethylene glycol under heating, and has anti-waxing properties. The thickn...

Embodiment 3

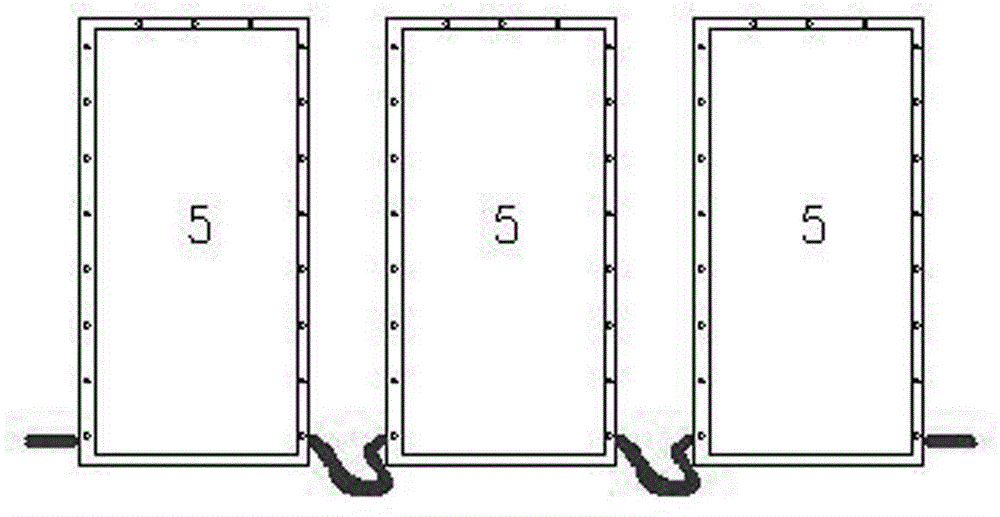

[0054] A connection and installation method of the present invention is given below.

[0055] like figure 2 Shown is a preferred embodiment of an anti-condensation metal radiant panel and a manufacturing method thereof according to the present invention figure 1 Schematic diagram of the connection between the anti-condensation metal radiant panels:

[0056] The radiant panel and the radiant panel can be connected by hard connection (usually by heat fusion welding), or can be connected by flexible hose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com