UV woodware laser roller-coating white finish coat and preparation method thereof

A laser roller, white technology, applied in the field of UV wood laser roller coating white topcoat coating and its preparation, can solve the problems of poor whiteness, poor hand feeling, less coating amount, etc., and achieve high scratch resistance, whiteness The effect of good hiding power and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

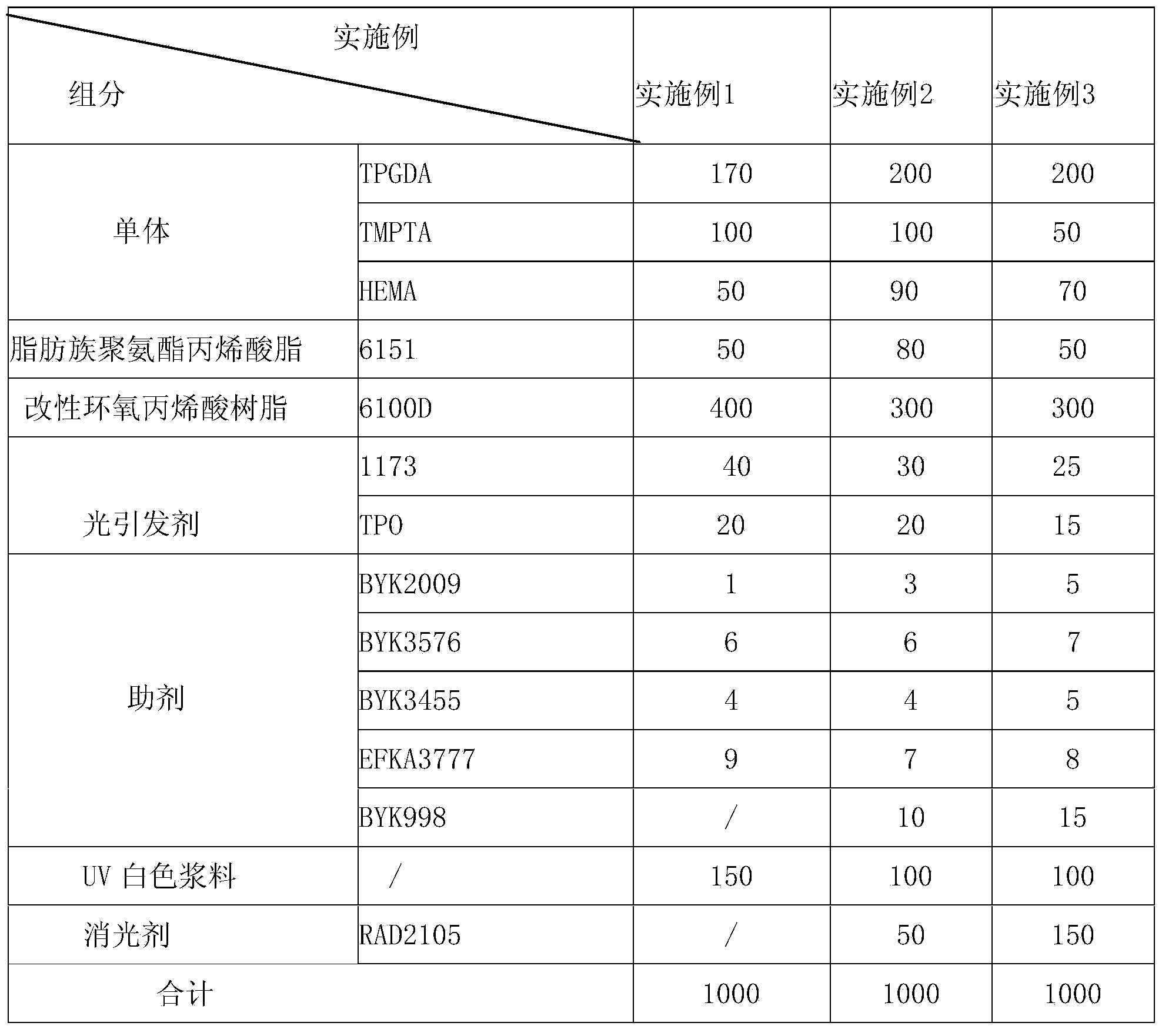

[0034] Embodiment 1 is that the UV woodware laser roller is coated with bright light white topcoat, so it has not added matting agent in its formula; Embodiment 2 is that the UV woodware laser roller is coated with semi-dumb white topcoat, so a small amount of matting agent has been added in its formula; Example 3 is a full matt white topcoat for UV wood laser roller coating, so a matting agent is added in its formula.

[0035] The raw material components and weight formulations (unit: kg) of Examples 1-3 are shown in Table 1.

[0036]

[0037] Table 1

[0038]Among them, the polyurethane acrylate acrylate used in the present invention, modified epoxy acrylic resin, functional monomer trimethylolpropane triacrylate (TMPTA), tripropylene glycol diacrylate (TPGDA), 1,6-ethylene glycol Diacrylate (HDDA), 13-hydroxyethyl methacrylate (HEMA), propoxylated neopentyl glycol diacrylate (2PO-NPGDA), and UV white paste, matting powder is used as a component in the coating system Me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com