Compound with a plurality of active groups and preparation method of compound

A technology of active groups and compounds, which is applied in the field of compounds containing multiple active groups and their preparation, can solve problems such as easy combustion, and achieve the effects of good carbon-forming performance, simple equipment and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

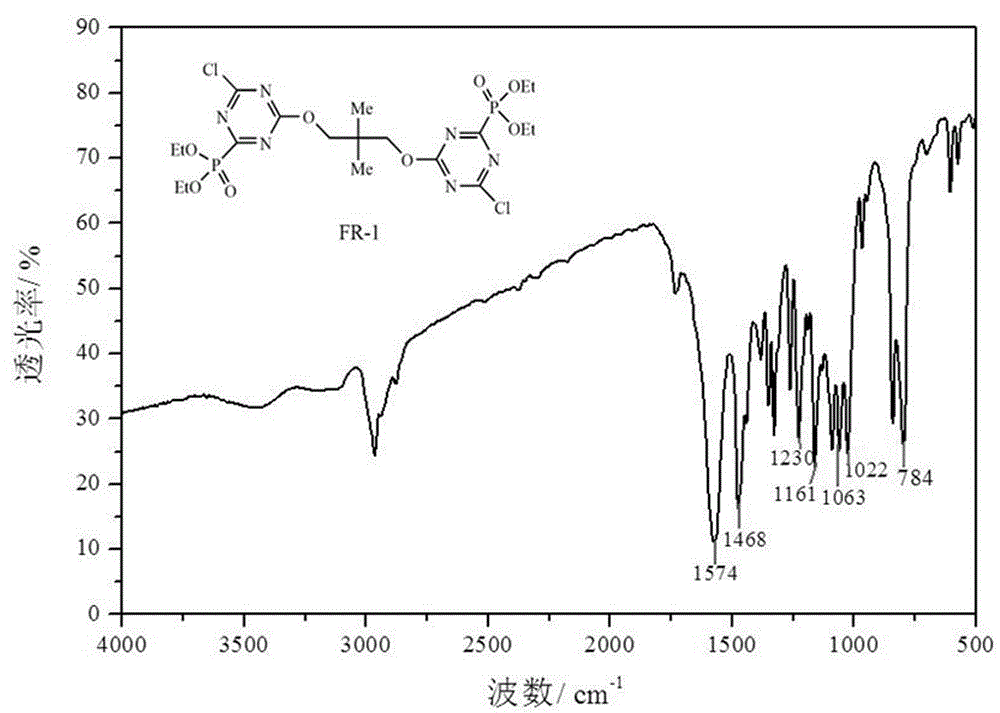

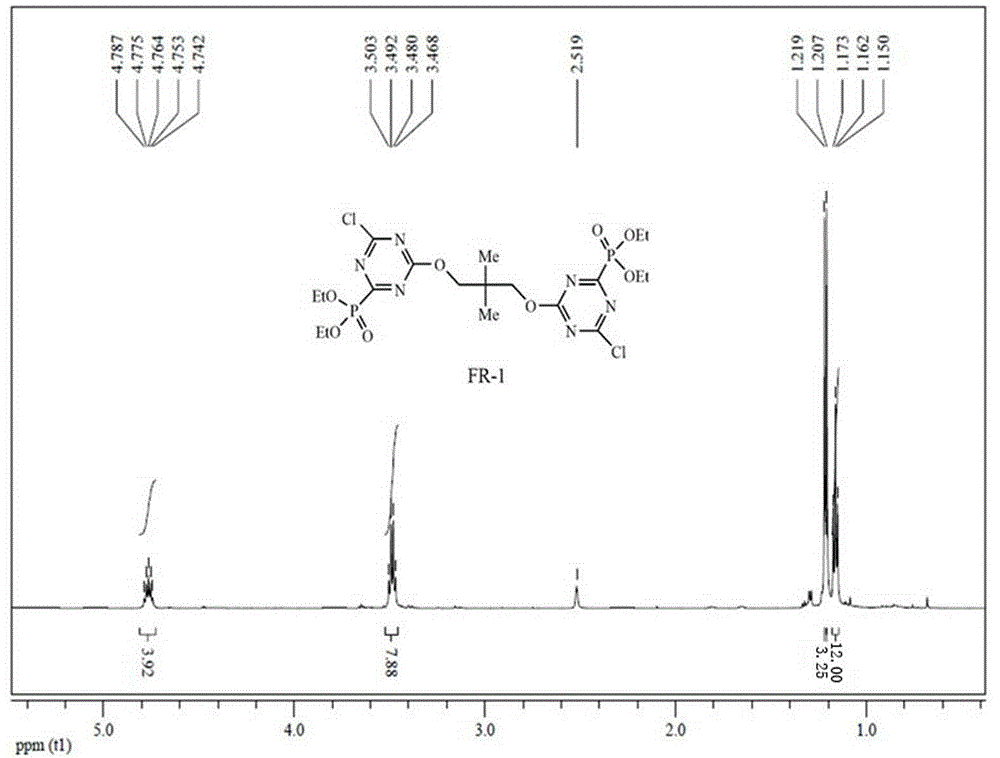

Embodiment 1

[0037] The preparation method of the compound (FR-1) containing multiple active groups,

[0038] The steps are:

[0039] first step,

[0040] (1) Weigh 5.52g (0.03mol) of cyanuric chloride and dissolve it in 50mL of toluene, stir until completely dissolved, slowly raise the temperature to 60°C, keep stirring while keeping warm, so that the reactants are evenly dispersed;

[0041] (2) Under nitrogen protection atmosphere, add 5.48g (0.033mol) triethyl phosphite solution dissolved in 50mL acetone, react for 4h, keep stirring during the reaction;

[0042] (3) After the reaction is over, stop the heat preservation, gradually cool to room temperature, filter, and rotary evaporate to obtain intermediate M;

[0043] second step,

[0044] (4) Dissolve 5.72g (0.02mol) of intermediate M in 50mL of tetrahydrofuran, stir until completely dissolved, slowly raise the temperature to 60°C, keep stirring while keeping warm, so that the reactants are evenly dispersed;

[0045] (5) Weigh 1.0...

Embodiment 2

[0049] The preparation method of the compound (FR-1) containing multiple active groups,

[0050] The steps are:

[0051] first step,

[0052] (1) Weigh 9.30g (0.05mol) of cyanuric chloride and dissolve it in 80mL of acetone, stir until completely dissolved, slowly raise the temperature to 60°C, keep stirring while keeping warm, so that the reactants are evenly dispersed;

[0053] (2) Under nitrogen protection atmosphere, add 6.20g (0.05mol) trimethyl phosphite solution dissolved in 80mL toluene and acetone mixed solvent (1:2 volume ratio), react for 6h, keep stirring during the reaction ;

[0054] (3) After the reaction is over, stop the heat preservation, gradually cool to room temperature, filter, and rotary evaporate to obtain intermediate M;

[0055] second step,

[0056] (4) Dissolve 9.76g (0.04mol) of intermediate M in 80mL of 1,4-dioxane, stir until completely dissolved, slowly raise the temperature to 55°C, keep stirring while keeping warm, so that the reactants ar...

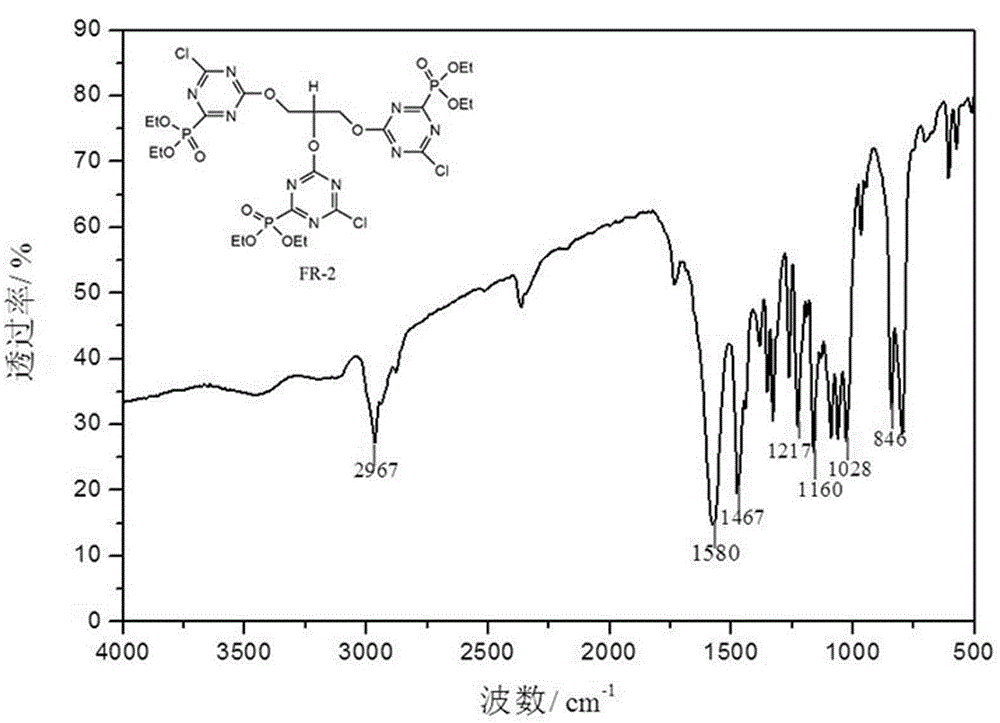

Embodiment 3

[0060] The preparation method of the compound (FR-2) containing multiple active groups,

[0061] The steps are:

[0062] first step,

[0063] (1) Weigh 7.44g (0.04mol) of cyanuric chloride and dissolve it in 70mL of 1,4-dioxane, stir until completely dissolved, slowly raise the temperature to 60°C, keep stirring while keeping warm, so that the reactants are evenly dispersed;

[0064] (2) Under nitrogen protection atmosphere, add 7.30g (0.044mol) triethyl phosphite solution dissolved in 50mL 1,4-dioxane, react for 5h, keep stirring during the reaction;

[0065] (3) After the reaction is over, stop the heat preservation, gradually cool to room temperature, filter, and rotary evaporate to obtain intermediate M;

[0066] second step,

[0067] (4) Dissolve 8.58g (0.03mol) of intermediate M in 70mL of tetrahydrofuran, stir until completely dissolved, slowly raise the temperature to 40°C, keep stirring while keeping warm, so that the reactants are evenly dispersed;

[0068] (5) W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com