Preparation method of hindered amine light stabilizer 770

A technology of hindered amines and light stabilizers, which is applied in the field of preparation of hindered amine light stabilizers 770, which can solve the problems of unqualified light transmittance, unqualified light transmittance, and presence of carboxyl groups, etc., so as to facilitate large-scale production , low equipment requirements and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

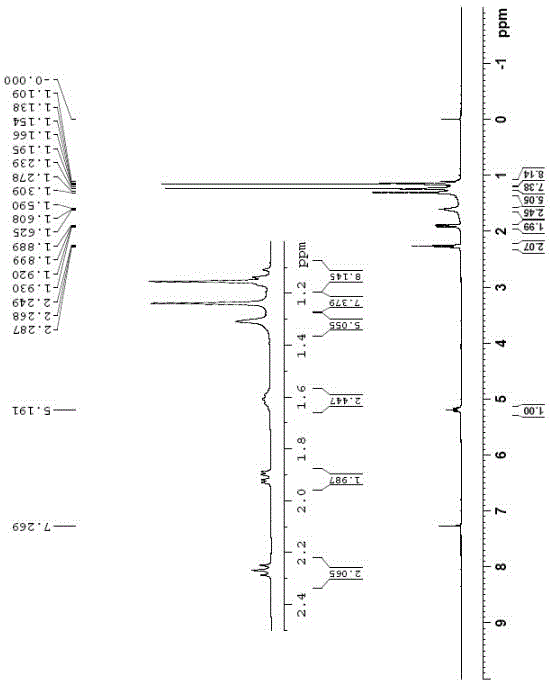

Image

Examples

Embodiment 1

[0030] This embodiment provides a preparation method of hindered amine light stabilizer 770, specifically as follows:

[0031] In a 500ml four-neck flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.37mol (75.33g) of sebacic acid, 0.76mol (120.15g) of tetramethylpiperidinol, and 3.88g of dioctyltin oxide at room temperature and 213.5g of trimethylbenzene, slowly warming up to the reflux temperature under stirring, and keeping it at 170°C-175°C for 4h under reflux and water separation. During the reaction process, the reaction process is judged by GC analysis of the ratio of mono- and di-esters generated by the reaction, and the reaction is controlled to the end.

[0032] After the reaction, the solution was cooled to 80° C., the catalyst was removed by filtration, and trimethylbenzene was distilled off under reduced pressure. Add equal weight of petroleum ether and 3.5g of activated carbon to the remaining material, heat to 60°C-70°C and stir for 1h, ...

Embodiment 2

[0034] This embodiment provides a preparation method of hindered amine light stabilizer 770, specifically as follows:

[0035] In a 500ml four-neck flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.37mol (75.33g) of sebacic acid, 0.76mol (120.15g) of tetramethylpiperidinol, and 3.88g of dioctyltin oxide at room temperature and 213.5 g of trimethylbenzene, slowly warming up to the reflux temperature with stirring, and keeping at 175° C. for reflux and water separation reaction for 6 h. During the reaction process, the reaction process is judged by GC analysis of the ratio of mono- and di-esters generated by the reaction, and the reaction is controlled to the end.

[0036] After the reaction, the solution was cooled to 80° C., the catalyst was removed by filtration, and trimethylbenzene was distilled off under reduced pressure. Add equal weight of water and 3.5g of activated carbon to the remaining material, heat to 60°C-70°C and stir for 1h, then filt...

Embodiment 3

[0038] This embodiment provides a preparation method of hindered amine light stabilizer 770, specifically as follows:

[0039] In a 500ml four-neck flask equipped with a stirrer, a thermometer, and a reflux condenser, add 0.37mol (75.33g) of sebacic acid, 0.76mol (120.15g) of tetramethylpiperidinol, and 3.88g of stannous octoate at room temperature and 213.5 g of trimethylbenzene, slowly warming up to the reflux temperature with stirring, and keeping it at 170°C-175°C for 8h under reflux and water separation. During the reaction process, the reaction process is judged by GC analysis of the ratio of mono- and di-esters generated by the reaction, and the reaction is controlled to the end.

[0040] After the reaction, the solution was cooled to 80° C., the catalyst was removed by filtration, and trimethylbenzene was distilled off under reduced pressure. Add equal weight of petroleum ether and 3.5g of activated carbon to the remaining material, heat to 60°C-70°C and stir for 1h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com