Large-barrel water pressing device with two one-way valves

The technology of a water pressure water device and a one-way valve is applied in the field of daily necessities, which can solve the problems of laborious water pressure, inability to interrupt the water discharge action in time, inconvenience for users, etc., and achieve the effect of reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

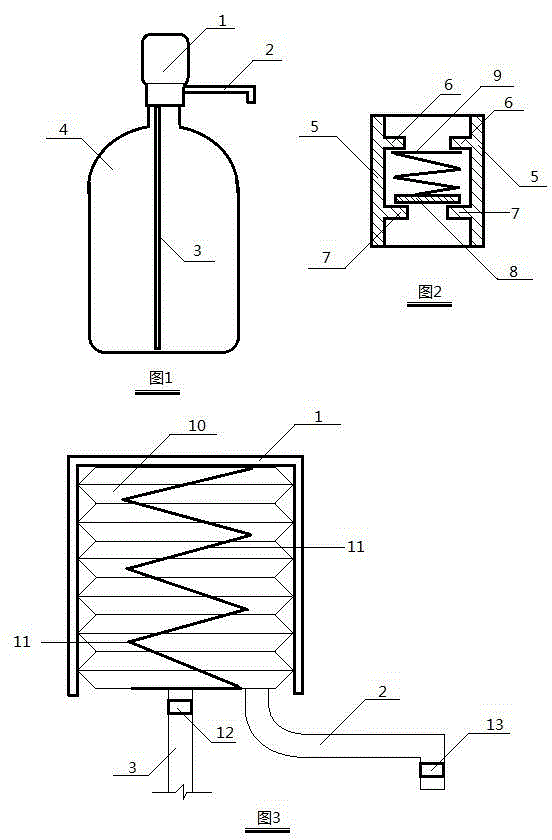

[0013] The large bucket water pressure water device 1 and the bucket body 4 of the large bucket water are connected to each other, and the inside of the large bucket water pressure water device 1 is installed with a closed cylinder 10 with annular folds, and an anti-corrosion spring is installed inside the closed cylinder 10 with annular folds 11. The water outlet pipe 2 and the water suction pipe 3 are respectively installed on the large bucket water pressure water device 1, and the one-way valve 12 on the water suction pipe is installed on the water suction pipe 3, and the one-way valve 13 on the water outlet pipe is installed on the water outlet pipe 2, The one-way valve 12 on the suction pipe and the one-way valve one-way valve 13 on the water outlet pipe have the same internal structure, all of which are composed of a one-way valve housing 5, a spring snap ring 6, a water outlet snap ring 7, a water outlet baffle plate 8 and Check valve internal spring 9 is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com