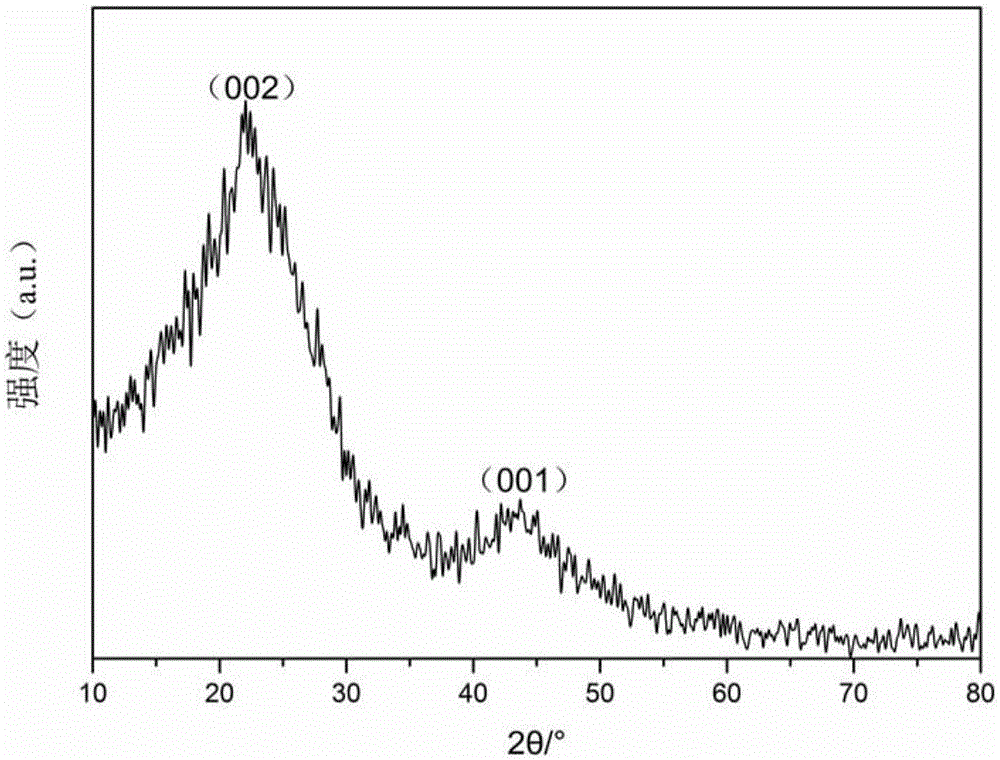

A two-step hydrothermal method for the preparation of mesoporous carbon-supported tio2 photocatalytic materials

A photocatalytic material and mesoporous preparation technology, applied in chemical instruments and methods, physical/chemical process catalysts, water pollutants, etc., can solve the problem of low degradation rate of photocatalytic materials, achieve simple equipment, mild preparation process, The effect of reducing the chance of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

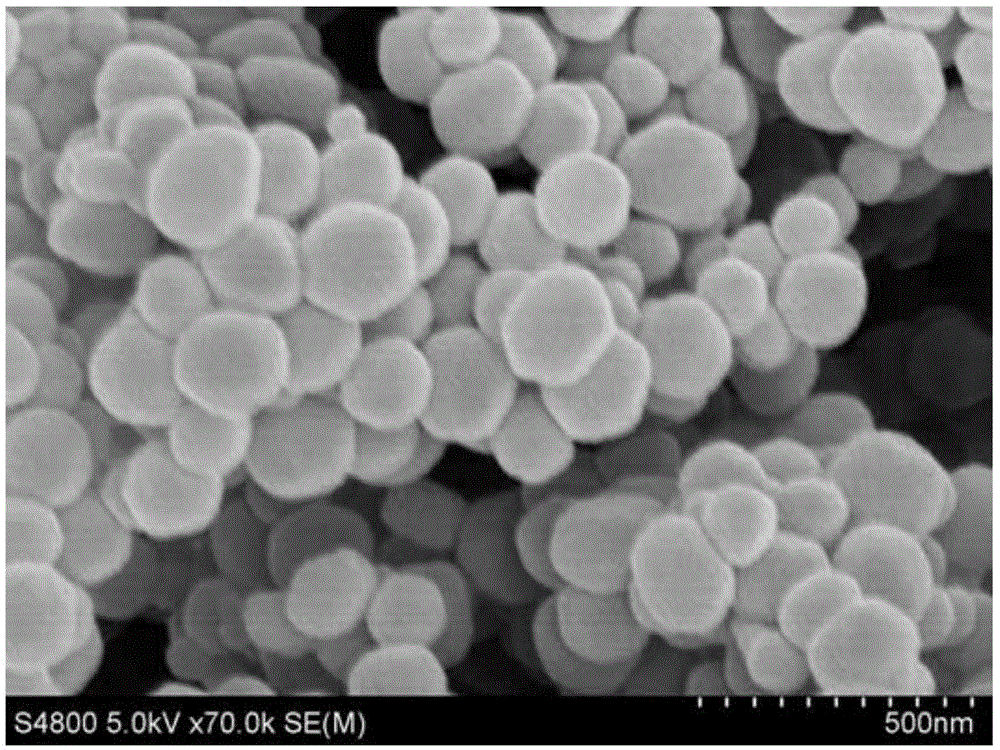

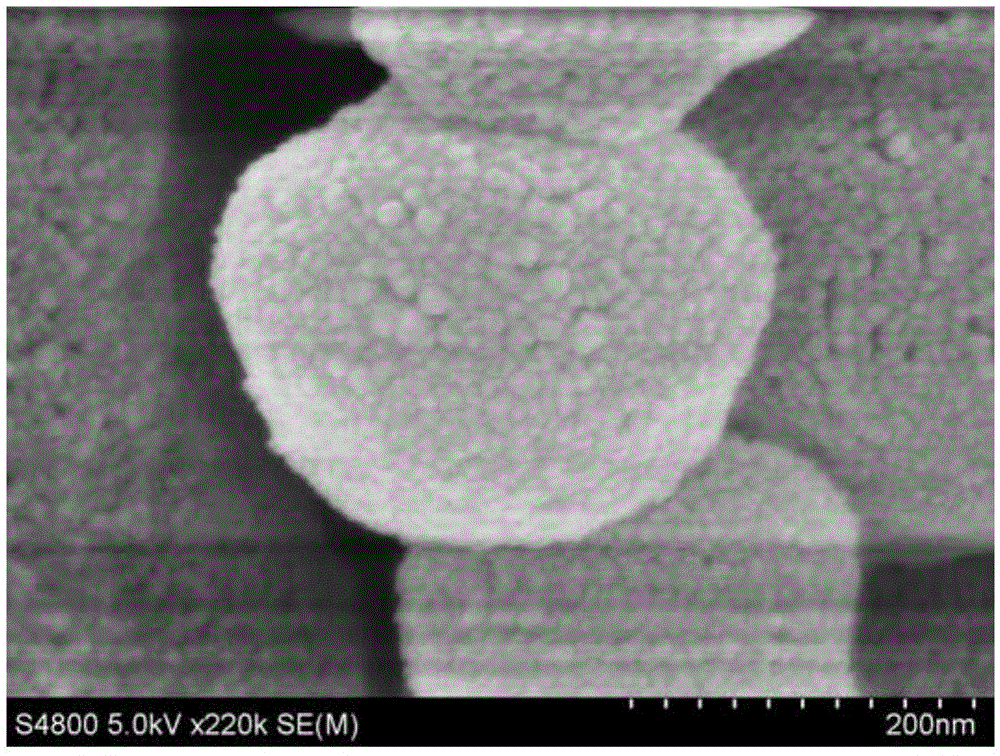

[0030] Specific implementation mode 1: In this implementation mode, two-step hydrothermal method is used to prepare mesoporous carbon-supported TiO 2 The method of photocatalytic material is carried out according to the following steps:

[0031] 1. Add resorcinol, melamine, and formaldehyde into deionized water and stir until completely dissolved to obtain solution A. The concentration of resorcinol in solution A is 5.5-11g / L, and the concentration of melamine is 3-12g / L , the concentration of formaldehyde is 8-24g / L;

[0032] 2. Add deionized water to F127, and stir until completely dissolved to obtain solution B. The concentration of F127 in solution B is 9-18g / L;

[0033] 3. Add solution B dropwise to solution A while stirring, the volume ratio of solution B to solution A is 2:1, stir for 2 to 4 hours to obtain a mixed solution;

[0034] 4. Put the mixed solution into a hydrothermal kettle, conduct a hydrothermal reaction at a hydrothermal temperature of 120-180°C for 6-1...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of resorcinol in solution A in step 1 is 11 g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the concentration of melamine in solution A in step 1 is 6 g / L. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com