Extinguishing agent for forest fire

A fire extinguishing agent and mountain fire technology, applied in the field of mountain fire extinguishing agents, can solve the problems of low fire extinguishing efficiency and resurgence of fire extinguishing agents, and achieve the effects of improving effective oxygen insulation and cooling capacity, reducing water consumption, and being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

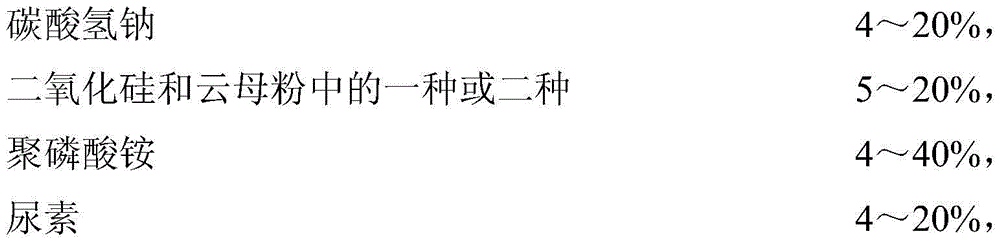

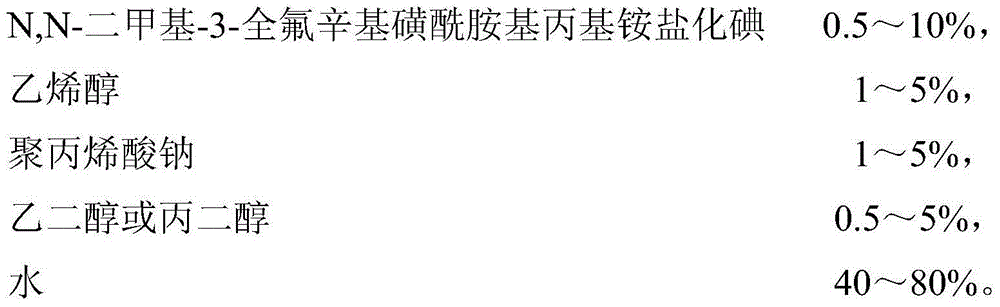

[0022] The components of this example mountain fire extinguishing agent include:

[0023]

[0024] The production method of this example mountain fire extinguishing agent comprises the following steps:

[0025] (1), the ammonium polyphosphate of described weight, urea are fully dissolved in the water of described weight to form mixed solution;

[0026] (2), adding the N,N-dimethyl-3-perfluorooctylsulfonamidopropylammonium iodine salt, vinyl alcohol, sodium bicarbonate, sodium polyacrylate, ethylene glycol of the weight successively, stirring Uniform;

[0027] (3), add the silicon dioxide of described weight, stir evenly.

Embodiment 2

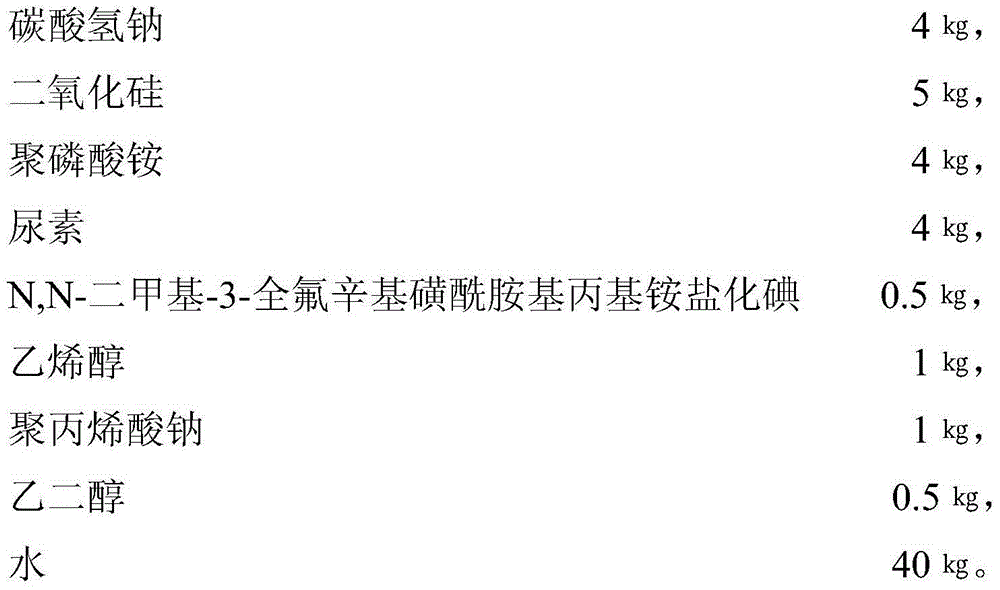

[0029] The components of this example mountain fire extinguishing agent include:

[0030]

[0031] The production method of this example mountain fire extinguishing agent comprises the following steps:

[0032] Step (1) is with embodiment 1;

[0033] (2), add the N,N-dimethyl-3-perfluorooctylsulfonamidopropylammonium iodine salt, vinyl alcohol, sodium bicarbonate, sodium polyacrylate, propylene glycol of the weight in sequence, and stir evenly;

[0034] (3), add silicon dioxide and mica powder of described weight, stir evenly.

[0035] The mountain fire fire extinguishing agent of the above two embodiments is diluted with water at a ratio of 1:10 when used, and then poured into a fine water mist fire extinguisher to implement spraying fire extinguishing. The experimental results of the trial production show that its fire extinguishing efficiency reaches GB15308-2006 standard water fire extinguishing efficiency or the fire extinguishing efficiency of foam fire extinguishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com