Drill bit for CFRP machining and experimental determining method for structural parameters of drill bit

A technology for structural parameters and determination methods, which is applied in the field of mechanical processing and can solve the problems that the overall optimization effect is not obvious, and the determination method of the structural parameters of the special drilling tool for carbon fiber reinforced composite materials is not found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

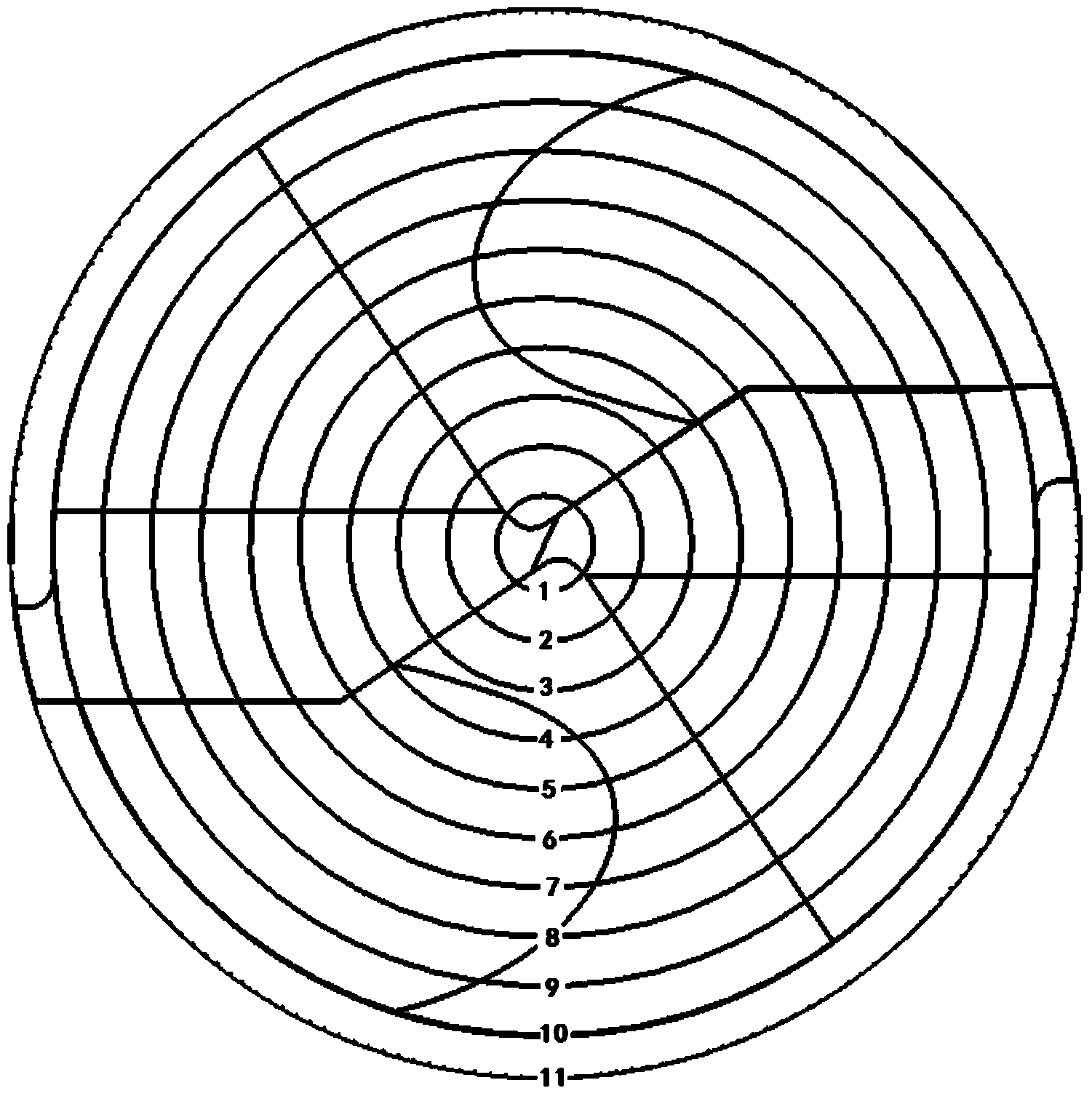

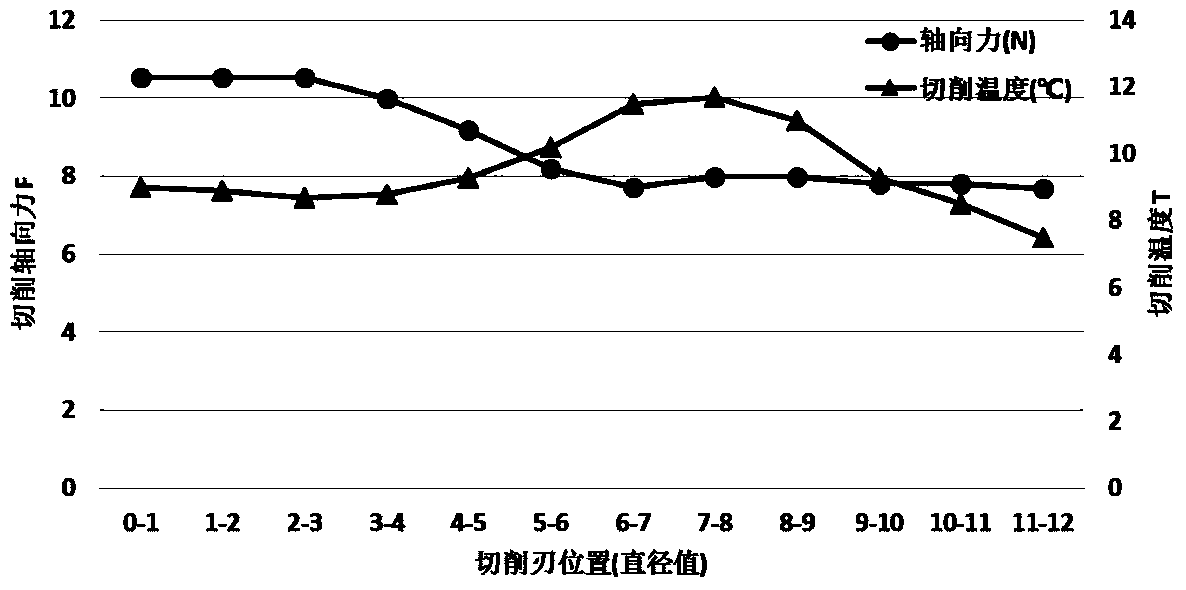

[0084] In this embodiment, a cemented carbide twist drill with a diameter of 12mm is used to drill and process T800CFRP laminates, and the cutting force and cutting temperature distribution on the cutting edge are measured as follows: figure 2 shown. After processing the experimental data, the following fitting formula is obtained:

[0085] F(x)=11.15x 3-12.76x 2 -1.02x+10.84,

[0086] T(x)=-37.77x 3 +44.48x 2 -10.35x+9.33.

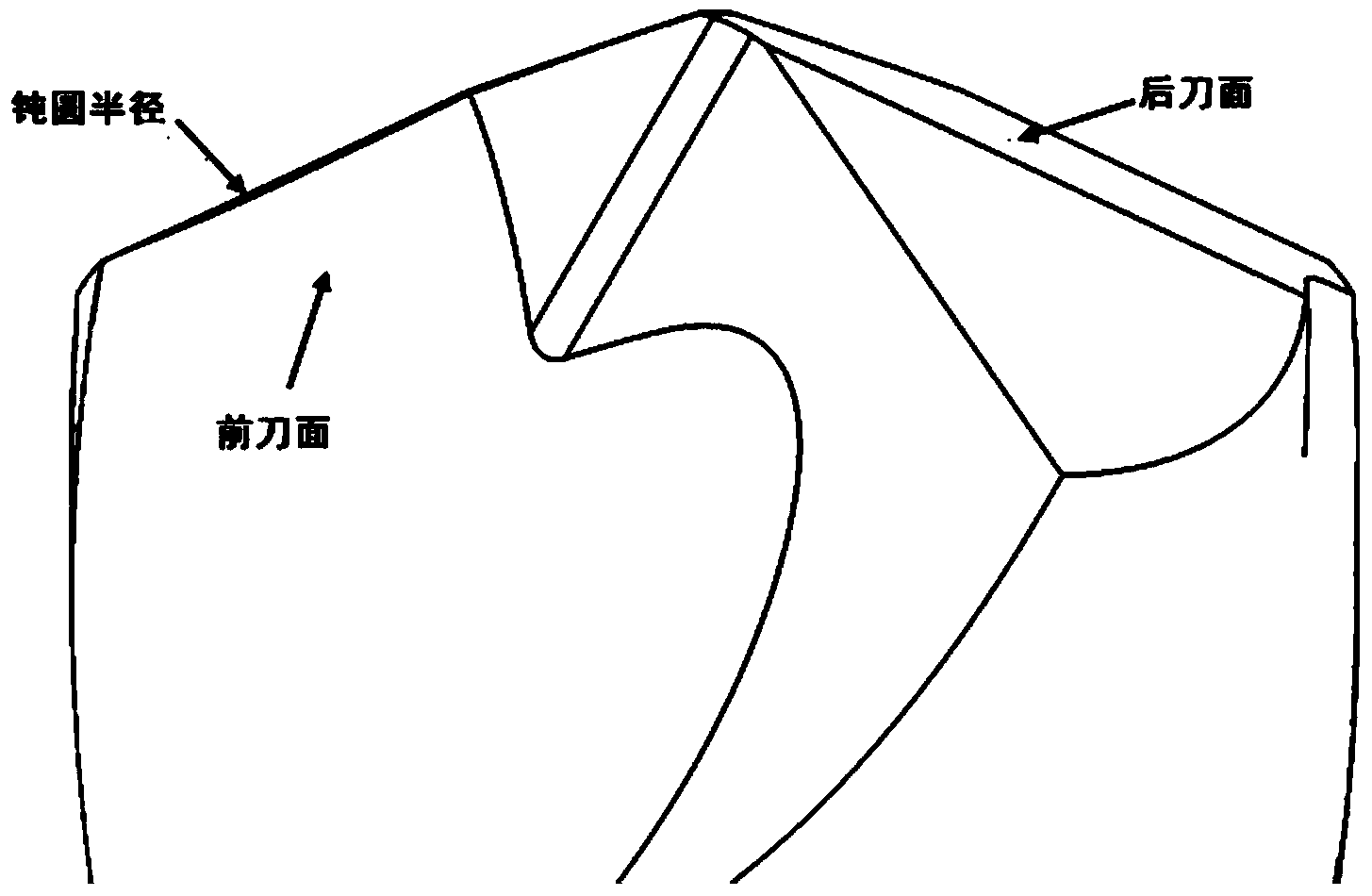

[0087] Adopt cutting speed V=200m / min, cutting depth a p =20μm is the experimental parameter, and the orthogonal free cutting experiment of CFRP is carried out, in which the rake angle adopts five levels of 5°, 10°, 15°, 20° and 25°, and the rear angle adopts 5°, 10°, 15°, 20° ° and 25° five levels, the radius of the blunt circle adopts five levels of 5μm, 10μm, 15μm, 20μm and 25μm to measure the cutting force and cutting temperature, and divide the cutting force and cutting temperature by the plate thickness to obtain the cutting force and cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com