Catalytic combustion reactor and process for removing hydrogen in tail gas

A catalytic combustion and reactor technology, applied in the field of catalysis, can solve problems such as system safety, anode tail gas environmental pollution, etc., and achieve the effects of high energy efficiency, environmental friendliness and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

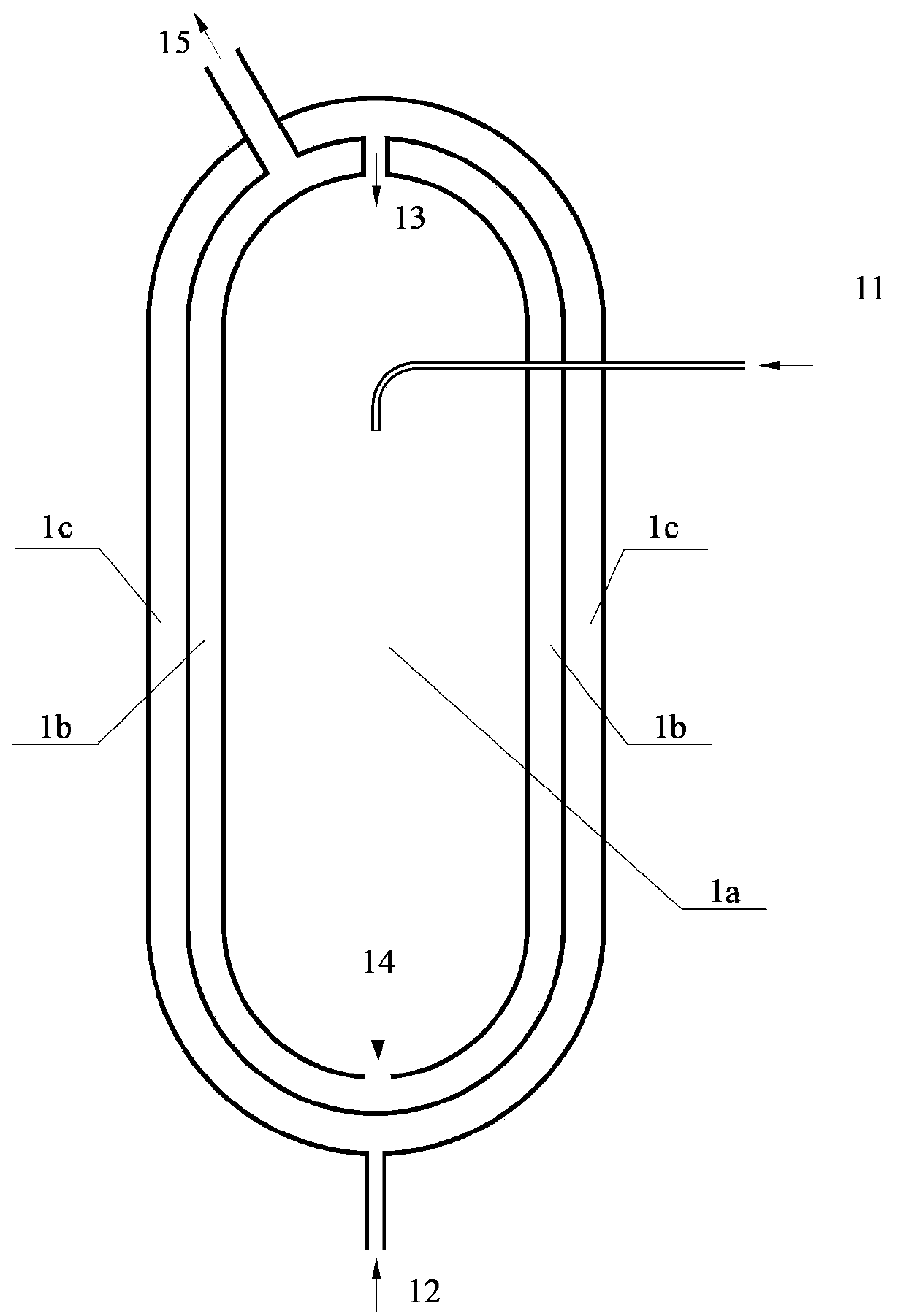

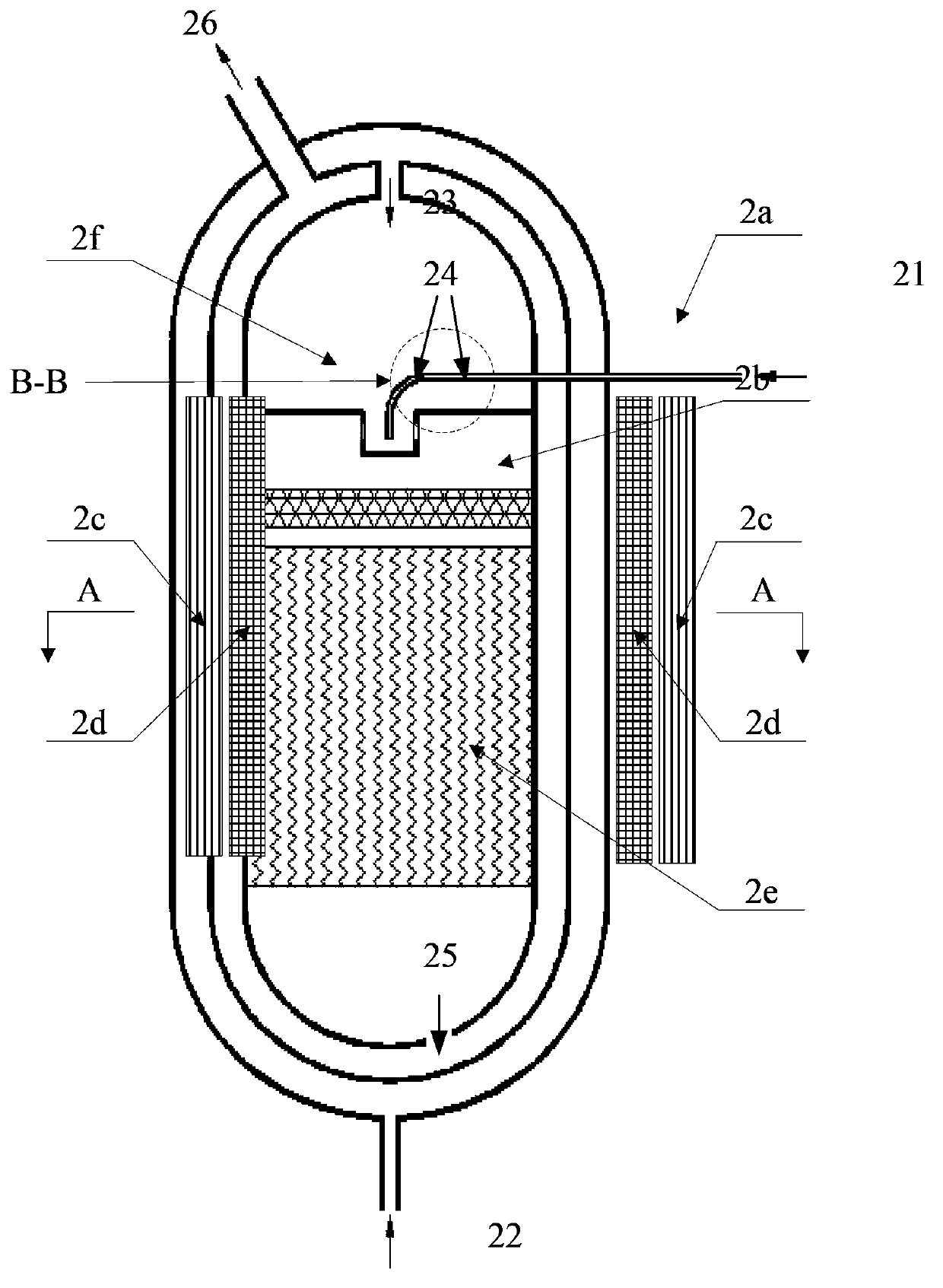

[0025] Catalytic combustion reactor for removing hydrogen in tail gas of the present invention ( figure 1 ), mainly including a catalytic combustion main area (1a) and two different heat exchange areas (1b and 1c). There are three cavities from the center to the outside, which are: catalytic combustion chamber (1a), combustion tail gas heat exchange chamber (1b) and hydrogen-containing tail gas heat exchange chamber (1c). First, a certain amount of air and the exhaust gas to be treated are respectively introduced into the reactor inlets (11) and (12), and the exhaust gas passes through the hydrogen-containing tail gas heat exchange chamber (1c), and then passes through the hydrogen-containing tail gas heat exchange chamber (1c) and the internal connecting channel (13) of the catalytic combustion chamber (1a) enters the catalytic combustion chamber (1a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com