Hydropower house foundation handling method

A technology for the treatment of powerhouses and foundations of hydropower stations, which is used in infrastructure engineering, sustainable buildings, sheet pile walls, etc. It can solve the problems of insufficient bearing capacity of weak foundations, seepage damage, and excessive settlement deformation, and improve the anti-vibration liquefaction ability. , Improve the bearing capacity of the foundation, the effect of good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

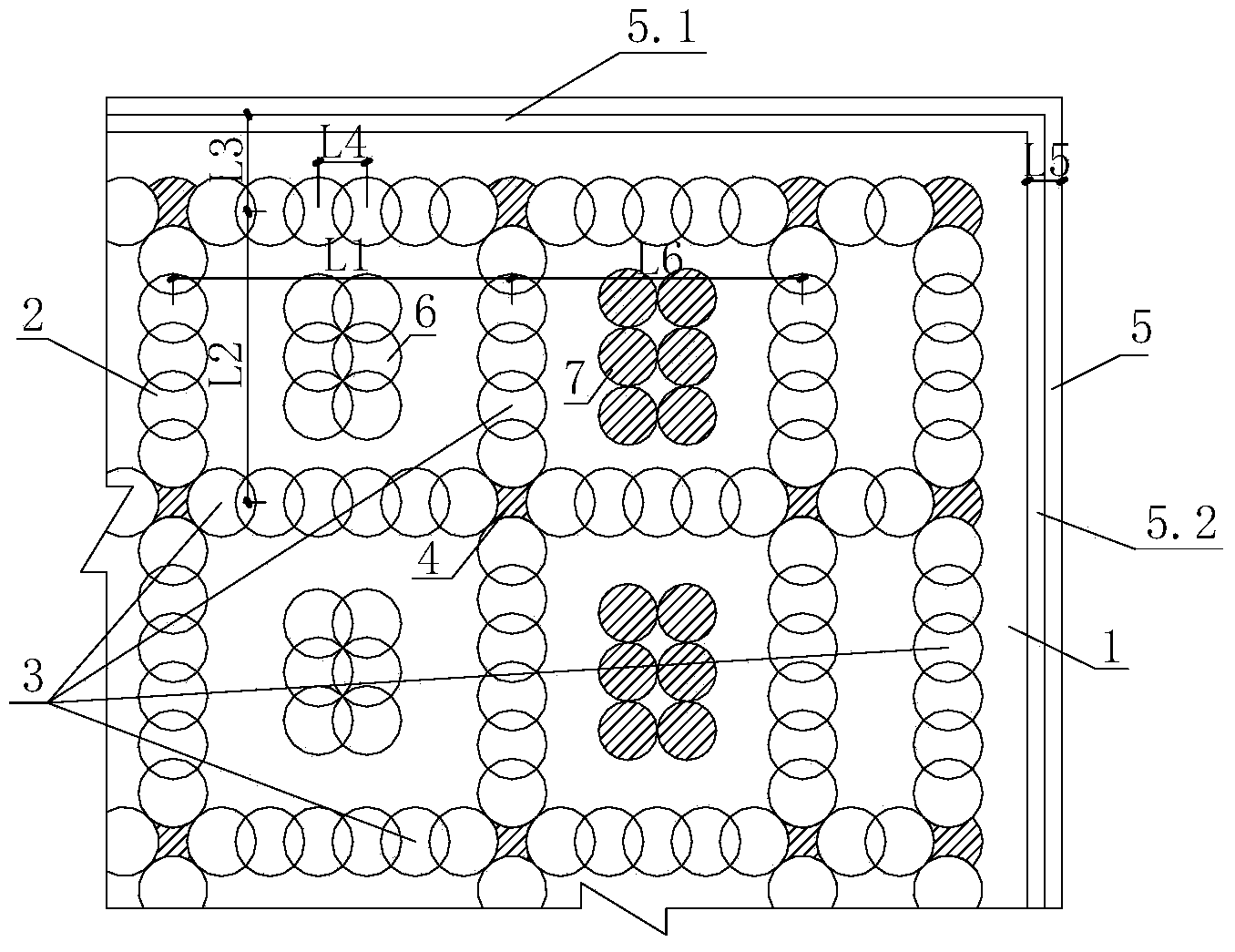

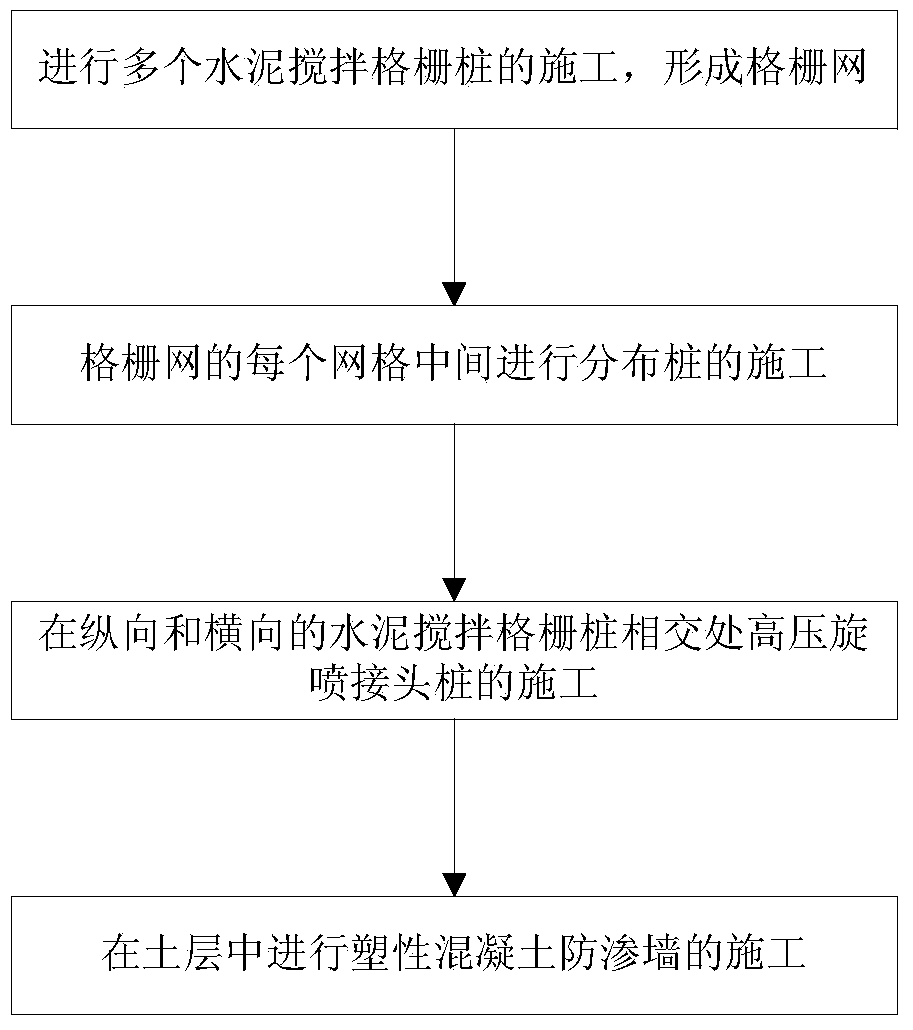

[0020] see figure 1 , the foundation involved in the method for treating the foundation of a hydropower station building in the present invention includes a soil layer 1, a grid net 3 composed of a plurality of cement mixing grid piles 2, a high-pressure rotary grouting joint pile 4, a plastic concrete cut-off wall 5, cement Stirring distribution pile 6 and high-pressure rotary jet distribution pile 7.

[0021] In this example, a water conservancy project located on the Jianghan alluvial plain is taken as an example. The powerhouse of the hydropower station is a river bed runoff power station. The bearing layer of the foundation is the fine sand layer of the lower part of the Holocene, with a thickness of about 6m, and the underlying sand and gravel layer, with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com