A kind of short fiber spinning method

A short fiber and fiber technology, which is applied in the field of short fiber spinning, can solve problems such as large environmental impact, and achieve the effects of increasing moisture content, increasing production costs, and improving quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

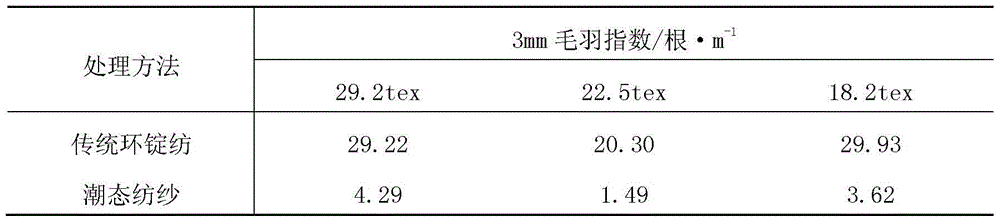

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] In the spinning method provided by the present invention, the staple fiber is used as raw material to be processed into yarn and needs to go through the following procedures:

[0016] The spinning method of the present invention has the same processes as the ring spinning method of the prior art: cotton blending process, coiling process, carding into sliver process, drawing frame process, combing process, roving process and spinning spun yarn process. The present invention is characterized in that a health-preserving process is added between the roving process and the spinning and spinning process, that is, the roving obtained in the roving process is placed in a closed space and filled with water vapor to increase the moisture content of the fibers in the roving and the inter-fiber relationship. Capillary moisture content.

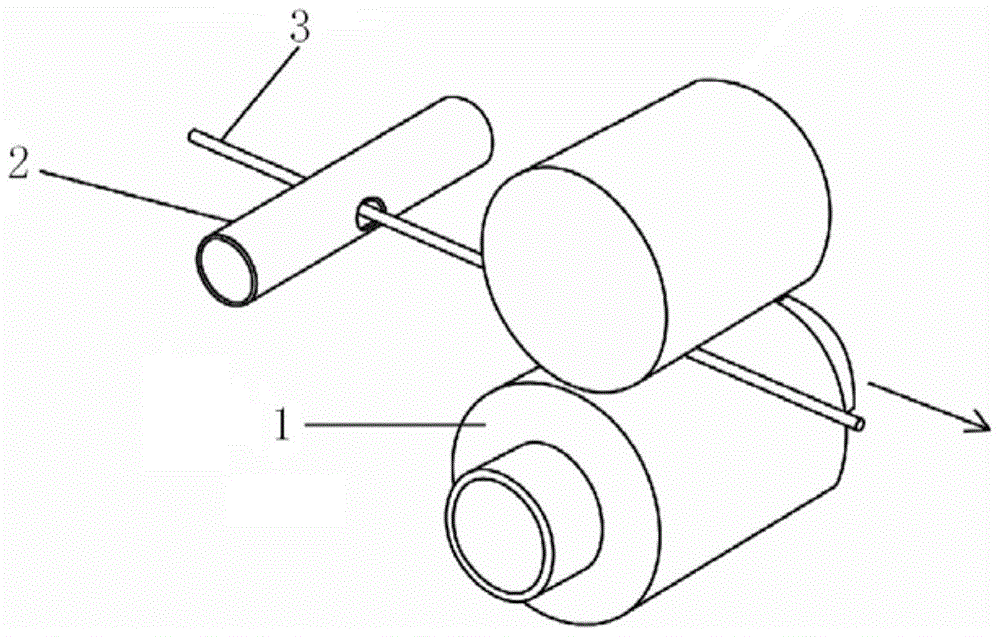

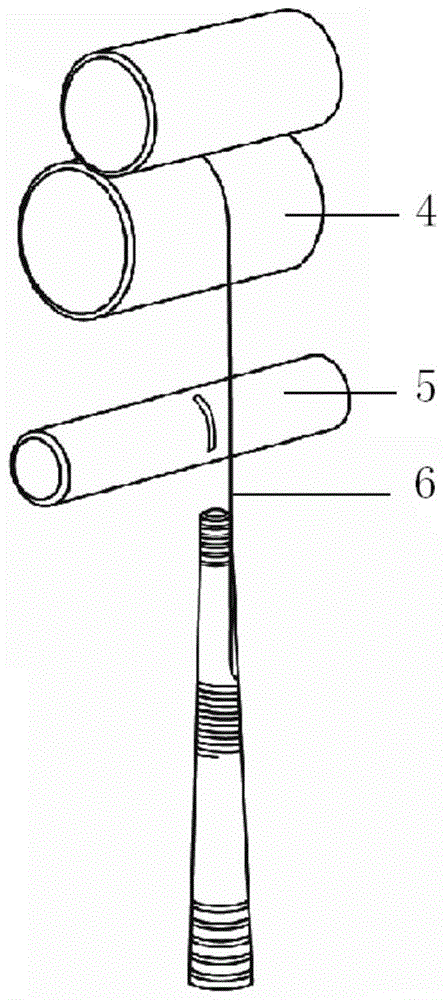

[0017] Such as figure 1 , figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com