Comprehensive recovery method of ferrous metallurgical solid wastes

A solid waste, iron and steel metallurgy technology, applied in the direction of improving process efficiency, can solve the problems of waste of resources, ineffective utilization of iron and steel metallurgy solid waste, environmental pollution, etc., and achieve good economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Table 1 shows the composition of iron and steel metallurgical solid waste such as blast furnace gas ash, sinter dust removal ash, and ironmaking furnace dust after mixing (the content is in mass percentage).

[0030] Table 1

[0031] TF K Na Pb Zn C Cl- 38.32 5.51 0.78 0.38 10.52 10.14 6.58

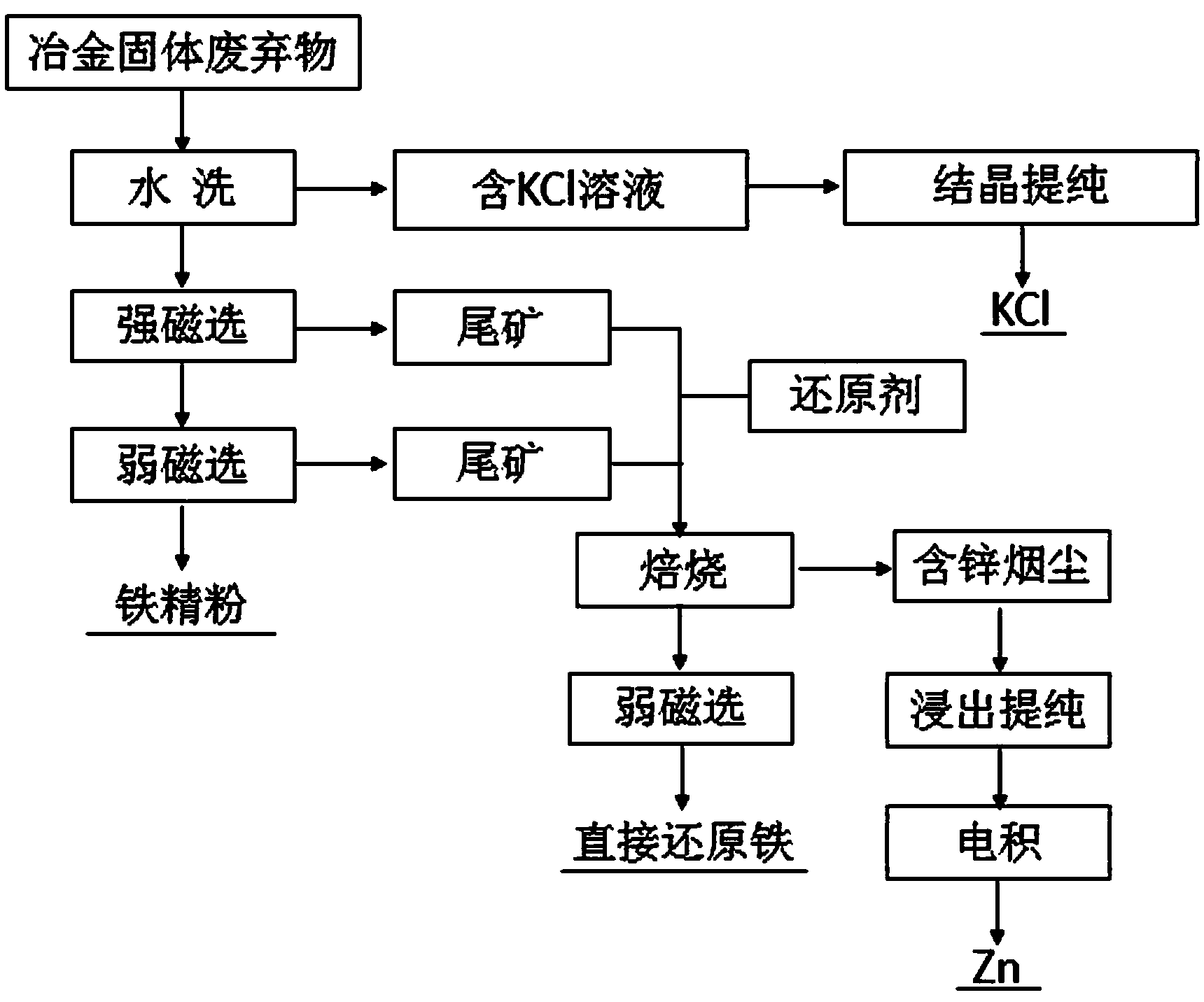

[0032] as attached figure 1 As shown, the method of comprehensive recycling of iron and steel metallurgical solid waste is as follows:

[0033] (1) Grind iron and steel metallurgical solid waste into 100% powder, leaching in water at 70-80°C, the liquid-solid ratio (solid-liquid mass ratio) is controlled at 2-4:1, and the stirring speed is 100-500 r / min , Stirring time 10-30min, making KCl immerse into the solution.

[0034] (2) Add Na to the leaching solution of KCl 2 S and K 2 SO 4 , to remove impurities in the leaching solution, and then carry out evaporation concentration and crystallization to extract KCl at a temperature of 95°C.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com