A kind of method for preparing dibasic acid dimethyl ester

A technology of dibasic acid dimethyl ester and dibasic acid, which is applied in the field of mixed ester preparation, can solve the problems of fixed bed inability to run for a long period and high energy consumption, achieve high catalytic activity and regeneration reuse rate, low energy consumption, The effect of avoiding cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

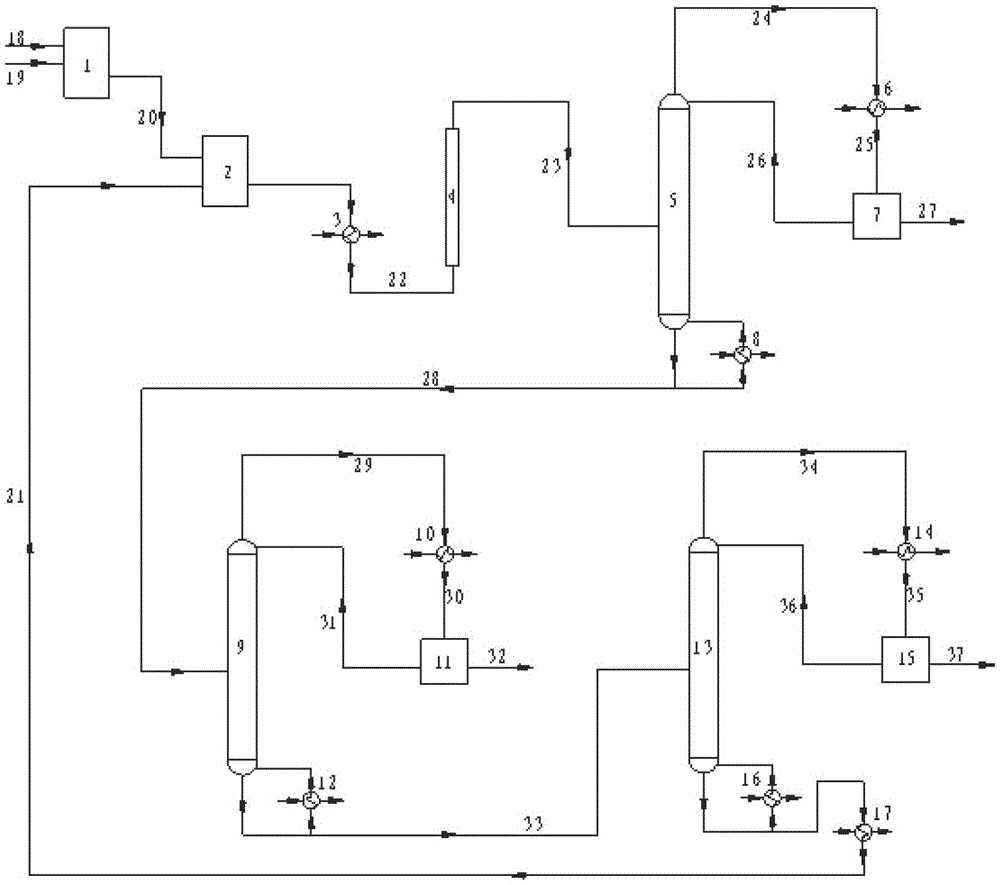

[0057] The process flow of the present invention is described according to the accompanying drawings. The content of each substance in the mixed dibasic acid used is: 35.7wt% adipic acid, 45.4wt% glutaric acid, 18.3wt% succinic acid, containing 0.03wt% malonic acid. Directly use industrial grade methanol for esterification. The alcohol-carboxyl ratio (the molar ratio of methanol to carboxyl groups) of the feed in Example 1 is 3.5:1. Both tank 1 and tank 2 were kept at 50°C. Esterification feed preheater 3 heats stream 22 to 60°C. The esterification reactor 4 was previously heated with a 60°C methanol stream and maintained at 60°C with a water bath jacket. The flow rate of the material in the esterification reactor is about 1.0BV / h. The material 22 enters 4 and reacts under the action of the catalyst, and the inside of the esterification reactor 4 is kept at 60°C. Column 5 maintains rectification at atmospheric pressure, the temperature at the top of the column is about 85...

Embodiment 2

[0059] In Example 2, purified adipic acid with a purity of 99.8-100.2 wt% and industrial grade methanol were used for esterification. The alcohol-carboxyl ratio (the molar ratio of methanol to carboxyl groups) of the feed in Example 1 is about 5:1. Both tank 1 and tank 2 were maintained at 60°C. Esterification feed preheater 3 heats stream 22 to 80°C. The esterification reactor 4 was previously heated with a methanol stream at 80°C and maintained at 80°C with a water bath jacket. The material 22 enters 4 and reacts under the action of the catalyst, and the inside of the esterification reactor 4 is kept at 80°C. The material flow rate in the esterification reactor is about 1.0BV / h. Column 5 maintains rectification at atmospheric pressure, the temperature at the top of the column is about 85°C, and the reflux ratio is 0.8. Column 9 adopts atmospheric distillation, the temperature at the top of the column is about 125°C, and the reflux ratio is 0.8. The top pressure (absolut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com