Waste paper modified coated control release fertilizer and preparation method thereof

A technology for controlled-release fertilizers and waste newspapers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of difficulty in large-scale popularization and application, high raw material prices, and refractory degradation, and achieve excellent nutrient controlled release performance and power saving. and energy, overcome the effect of non-degradable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

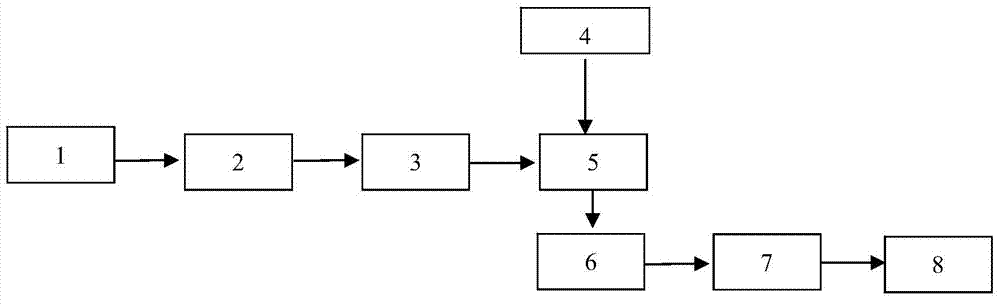

Method used

Image

Examples

Embodiment 1

[0029]Crush 100kg of waste newspapers into powders smaller than 2mm, put them into a reaction kettle with a heating device, and add 200kg-300kg of liquefaction agent (the liquefaction agent is palm oil: phenol: propylene carbonate (weight ratio) = 1:1: 1 mixture). Under the condition of constant stirring, rapidly raise the temperature to 120-150°C, then add concentrated phosphoric acid and concentrated sulfuric acid successively according to 1‰ and 2‰ of the powder weight of newspaper or cardboard box, and keep stirring for about 25-30 minutes , which converts recycled waste newspaper or cardboard box powder into liquefied matter. Mix the liquefied product with the modifier (a mixture of sodium dodecylbenzenesulfonate containing a weight ratio of 1‰ in hydroxyl-terminated polydimethylsiloxane) according to a weight ratio of 100:0.1, and maintain a temperature of 60 ℃-80℃, the modification can be completed in about 20-30 minutes under the condition of constant stirring. Add 1...

Embodiment 2

[0031] Crush 100kg of waste newspapers into powders smaller than 2mm, put them into the reaction attachment with a heating device, add 200kg-300kg of liquefaction agent (palm oil, phenol and propylene carbonate are mixed in a weight ratio of 1:1.5:1 as a liquefaction agent ). Under the condition of constant stirring, rapidly raise the temperature to 120-150°C, then add concentrated phosphoric acid and concentrated sulfuric acid successively according to 1‰ and 2‰ of the powder weight of newspaper or cardboard box, and keep stirring for about 25-30 minutes , which converts recycled waste newspaper or cardboard box powder into liquefied matter. Mix the liquefied product with the modifier (hydroxyl-modified silicone oil, water-soluble polyether silicone oil, methylvinyl silicone oil, and hydroxyl-terminated polydimethylsiloxane in a weight ratio of 1:1:1:1, and then add the mixture Sodium dodecylbenzenesulfonate with a weight ratio of 1‰) is mixed according to a weight ratio of ...

Embodiment 3

[0033] Crush 100kg of recycled cardboard boxes into powders smaller than 2mm, put them into the reaction attachment with a heating device, add 200kg-300kg of liquefaction agent (palm oil, phenol and propylene carbonate are mixed into liquefaction agent according to the weight ratio of 1:1.5:1) ). Under the condition of constant stirring, rapidly raise the temperature to 120-150°C, then add concentrated phosphoric acid and concentrated sulfuric acid successively according to 1‰ and 2‰ of the powder weight of the newspaper or cardboard box, and under the condition of continuous stirring, about 25-30 In minutes, recycled waste newspaper or cardboard box powder can be converted into liquefied matter. Mix the liquefied product with the modifier (hydroxyl-modified silicone oil, water-soluble polyether silicone oil, methylvinyl silicone oil, and hydroxyl-terminated polydimethylsiloxane in a weight ratio of 1:1:1:1, and then add the mixture Sodium dodecylbenzenesulfonate (weight 1‰) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com