A low bleeding rate pumpable phosphogypsum and yellow phosphorus slag filling paste and its preparation method

A technology of phosphogypsum and yellow phosphorus slag, which is applied in the direction of solid waste management, climate sustainability, sustainable waste treatment, etc., can solve the problems of polluted mine water environment, low bleeding rate, and drainage difficulties, and achieve the expansion of mine production capacity , Increase the early strength and reduce the effect of filling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

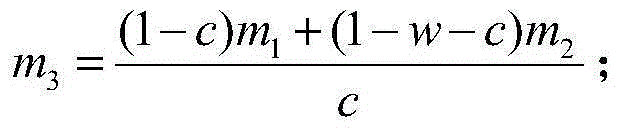

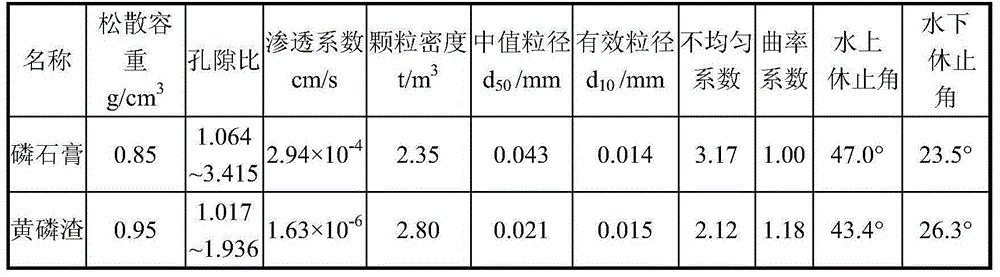

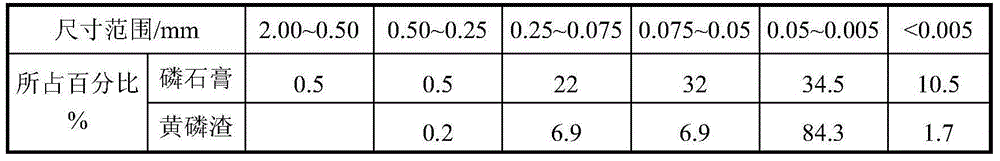

[0022] The main physical and mechanical properties of the phosphogypsum and yellow phosphorus slag used in the embodiment of the present invention are shown in Table 1, the particle size composition is shown in Table 2, and the main chemical components are shown in Table 3.

[0023] Table 1 Basic physical properties of phosphogypsum and yellow phosphorus slag

[0024]

[0025] Table 2 Composition of different particle sizes of phosphogypsum and yellow phosphorus slag

[0026]

[0027] Table 3 The main chemical composition of phosphogypsum and yellow phosphorus slag (unit, %)

[0028]

[0029] Select the phosphogypsum accumulation waste described in Table 1, Table 2, and Table 3, and after baking in a 55-60°C oven for 40 hours, measure its corresponding natural moisture content w=12.5%. The mass ratio of dry matter is 1:2, 1:4, 1:6, 1:8, and the target concentrations of 62%, 65%, 68%, 70%, and 72% of yellow phosphorus slag and phosphogypsum slurry are prepared respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com