multifunctional concrete reinforcement

A concrete reinforcement and multi-functional technology, applied in the field of concrete admixtures, can solve the problems that the technical performance cannot meet the engineering needs well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] First, add 495kg of polyether and 106kg of deionized water into the reaction vessel, when heated to 65°C, add 36kg of acrylic acid and 3kg of chlorine-free initiator dropwise into the reaction vessel, then cool down to 45°C, and then neutralize with 10kg of ionic membrane alkali And stir for 10 minutes to make it evenly mixed to make No. 1 mixture; add 110kg of triethanolamine, 150kg of surfactant, and 50kg of coagulation regulator to 40kg of deionized water, and fully stir at 45°C for 0.2 hours to make No. 2 mixture ; Then keep No. 1 mixture at about 45°C, slowly pour into No. 2 mixture while stirring, and fully stir for 0.5 hours to obtain a light yellow liquid that is not easy to precipitate, which is the product of the present invention.

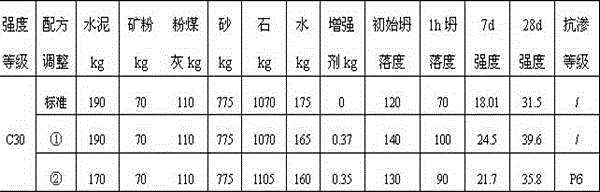

[0051] The multifunctional reinforcing agent provided by the invention has a strengthening effect on cement when the addition amount is 1 / 1000, and improves workability; under the condition that the standard formula condition of co...

Embodiment 2

[0054] First, add 445kg of polyether and 98kg of deionized water into the reaction vessel. When heated to 60°C, add 36kg of acrylic acid and 4kg of chlorine-free initiator dropwise into the reaction vessel, then cool down to 40°C, and then neutralize with 7kg of ionic membrane alkali. And stir for 15 minutes to make it uniformly mixed to make No. 1 mixture; add 120kg of triethanolamine, 160kg of surfactant, and 90kg of coagulation regulator to 30kg of deionized water, and fully stir at 40°C for 0.5 hours to make No. 2 mixture ; Then keep No. 1 mixture at 40°C, slowly pour into No. 2 mixture while stirring, and fully stir for 1 hour to obtain a light yellow liquid that is not easy to precipitate, which is the product of the present invention.

[0055] The multi-functional reinforcing agent provided by the present invention has an obvious strengthening effect on cement when the addition amount is 2 / 1000, and the workability is improved; the 7-day compressive strength of concrete ...

Embodiment 3

[0058] First, add 395kg of polyether and 90kg of deionized water into the reaction vessel. When heated to 55°C, add 35kg of acrylic acid and 5kg of chlorine-free initiator dropwise into the reaction vessel, then cool down to 35°C, and then neutralize with 5kg of ionic membrane alkali. And stir for 20 minutes to make it evenly mixed to make No. 1 mixture; add 130kg triethanolamine, 170kg surfactant, 130kg coagulation regulator to 20kg deionized water, and fully stir at 35°C for 1 hour to make No. 2 mixture ; Then keep No. 1 mixture at about 35°C, slowly pour into No. 2 mixture while stirring, and fully stir for 1.5 hours to obtain a light yellow liquid that is not easy to precipitate, which is the product of the present invention.

[0059] The multi-functional reinforcing agent provided by the present invention has a significant reinforcing effect on cement when the addition amount is 3 / 1000, and the workability is improved; the 7-day compressive strength of concrete can be incr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com