High-silicon-to-aluminum-ratio hierarchical beta zeolite and preparing method thereof

A beta zeolite, high silicon-aluminum ratio technology, applied in the field of molecular sieve preparation and post-modification, can solve the problems of high equipment requirements, complex operation, large energy consumption, etc., to reduce equipment requirements, simplify processing technology, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

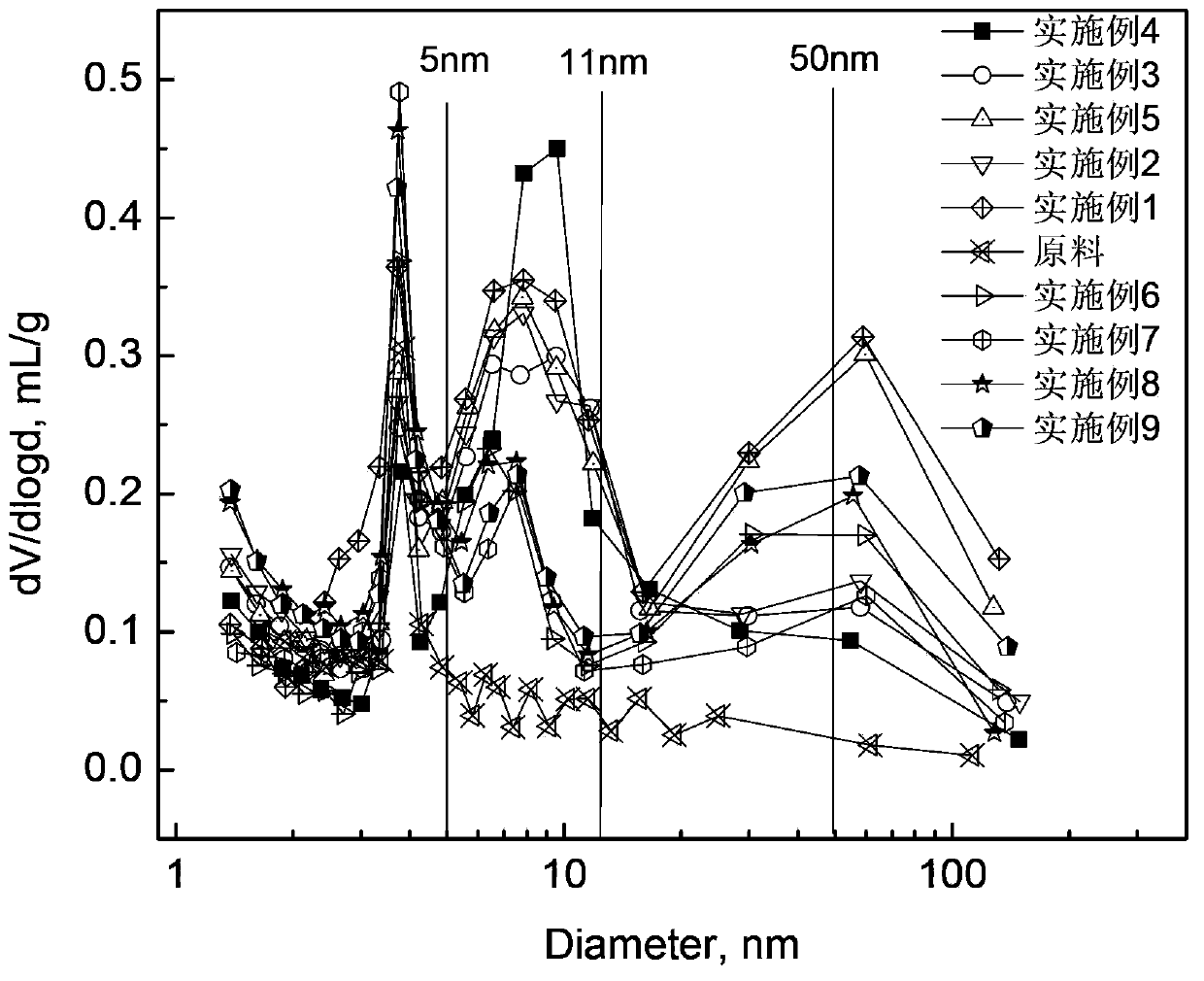

Examples

Embodiment 1

[0038] This embodiment provides a beta zeolite with a high silicon-aluminum ratio multi-stage channel, which is prepared by the following method:

[0039] Use beta zeolite raw powder as raw material, its silicon-aluminum ratio is 25, use 2mol / L hydrochloric acid with hydrochloric acid: raw material beta zeolite = 10:1 liquid-solid mass ratio to treat at 80 ℃ for 2 hours, after filtering and washing, at 120 Dry at ℃ for more than 5 hours to obtain beta zeolite after the first acid treatment;

[0040] The beta zeolite after the first acid treatment was placed in a muffle furnace, and after being roasted at 300°C for 2 hours, the temperature was raised to 550°C for 4 hours, and the heating rate was 4°C / min to obtain the first roasted beta zeolite;

[0041] Treat the beta zeolite after the first roasting with 2mol / L hydrochloric acid and hydrochloric acid:beta zeolite after the first roasting = 10:1 liquid-solid mass ratio at 80°C for 2h, after filtering and washing, at 120°C Un...

Embodiment 2

[0045] This embodiment provides a beta zeolite with high silicon-aluminum ratio multi-stage channels. Its preparation method and the raw material beta zeolite used are basically the same as in Example 1, except that 1.5mol / L hydrochloric acid is used for the first acidification. treatment and the second acid treatment.

[0046] The prepared beta zeolite was measured for its silicon-aluminum ratio, specific surface area and pore volume, and the results are shown in Table 1.

Embodiment 3

[0048] This embodiment provides a beta zeolite with high silicon-aluminum ratio multi-stage channels. Its preparation method and raw material beta zeolite are basically the same as in Example 1, except that 1.0mol / L hydrochloric acid is used for the first acidification. treatment and the second acid treatment.

[0049] The prepared beta zeolite was measured for its silicon-aluminum ratio, specific surface area and pore volume, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com