Connection method for films

A film and integrated technology, applied in the field of film manufacturing, can solve the problems of affecting the effect of film use, film discontinuity, film disconnection, etc., and achieve the effect of easy operation, simple method and easy access to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

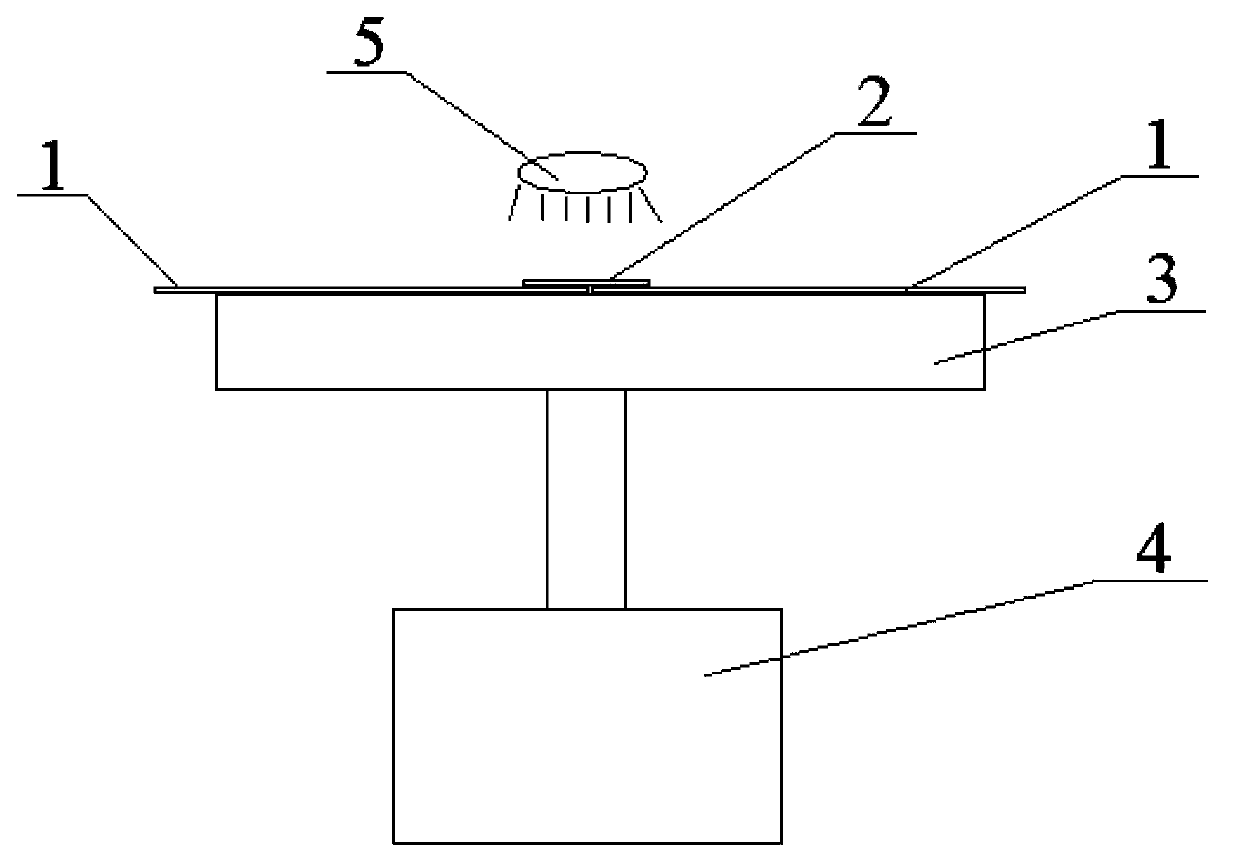

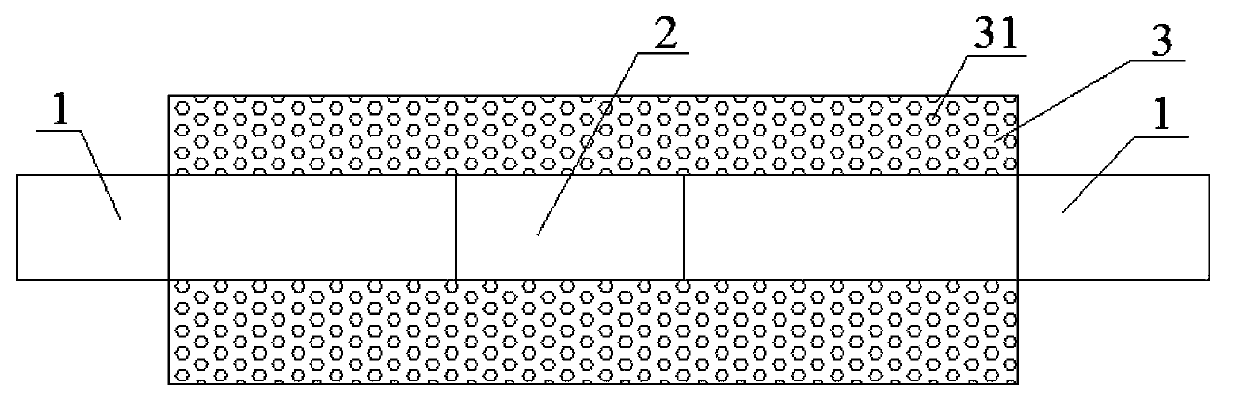

[0022] A method of joining thin films using a device such as figure 1 , figure 2 As shown, the method includes the following steps:

[0023] (1) The ends of the two sections of film 1 to be connected are cut neatly;

[0024] (2) Connect the box body 3 with the fine air port 31 on the flat surface to the vacuum device 4;

[0025] (3) Put the ends of the two neatly cut films 1 to be connected on the surface of the casing 3 provided with fine air ports 31;

[0026] (4) Open the vacuum device 4, so that the two sections of films 1 to be connected are flatly attached to the surface of the box body 3, and the ends of the films 1 to be connected are adjusted to be aligned;

[0027] (5) Coat the junction of the two sections of films 1 to be connected with UV-curable glue, and then place a neatly cut connection film 2 on the UV-curable glue;

[0028] (6) The connecting film 2 is irradiated with the ultraviolet light source 5 , and the ultraviolet light curing glue is cured to conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com