Welding apparatus

A welding device and welding process technology, applied in welding monitoring device, welding power source, welding power source and other directions, can solve the problems of inability to realize welding and deviation of oxide film damage phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

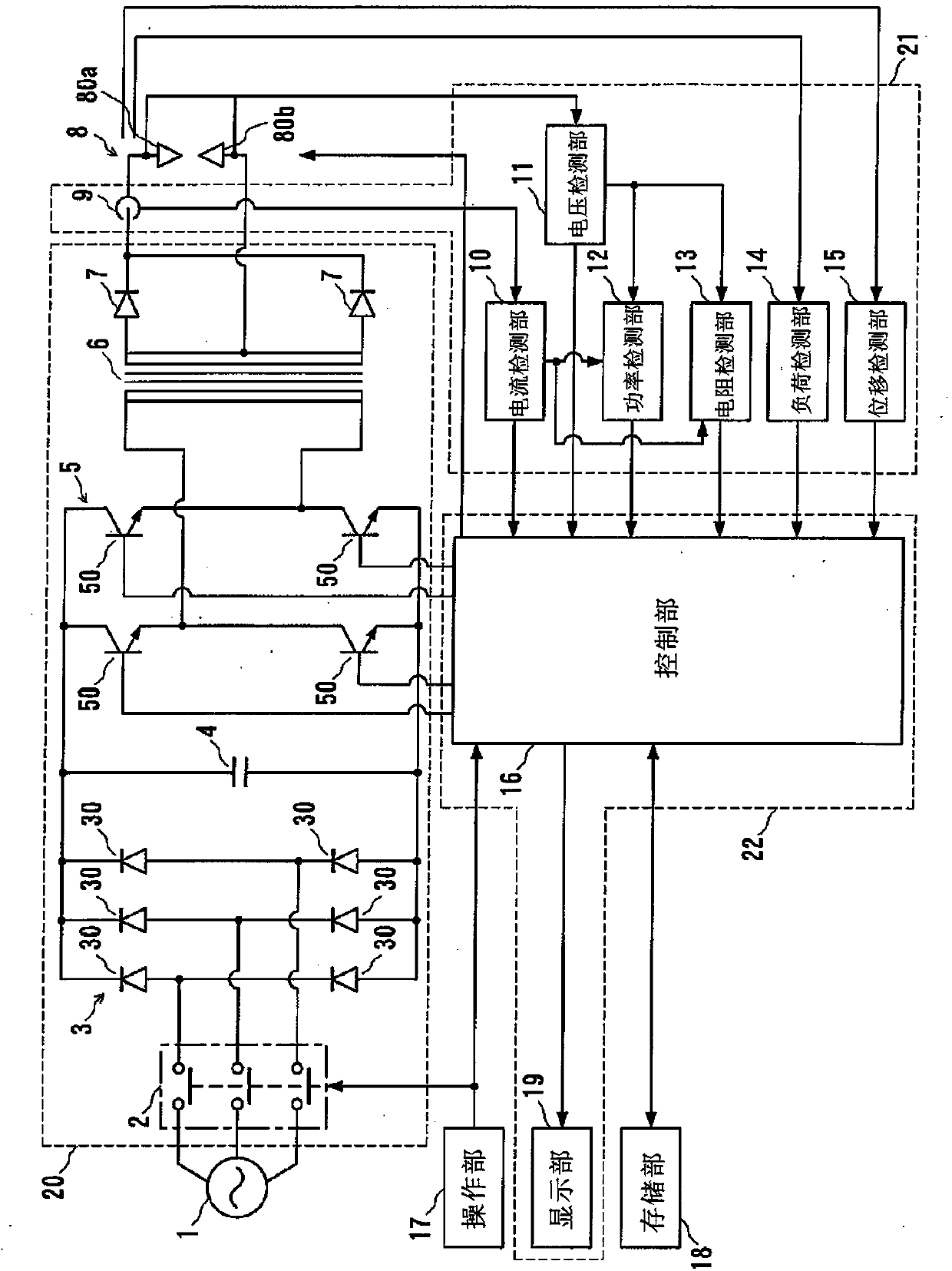

[0026] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a block diagram showing the configuration of the welding device according to the first embodiment of the present invention. The welding device of this embodiment includes a start switch 2, a rectifier circuit 3, a capacitor 4, a converter 5, a welding transformer 6, a diode 7, a welding head 8, a Hall element 9, a current detection part 10, a voltage detection part 11, a power detection part 12 , resistance detection part 13 , load detection part 14 , displacement detection part 15 , control part 16 , operation part 17 , storage part 18 and display part 19 .

[0027] A start switch 2 , a rectifier circuit 3 , a capacitor 4 , an inverter 5 , a welding transformer 6 , and a diode 7 constitute a welding power source 20 that supplies current to a welding head 8 . In addition, the Hall element 9, the current detection unit 10, the voltage detection unit 11, th...

no. 2 Embodiment

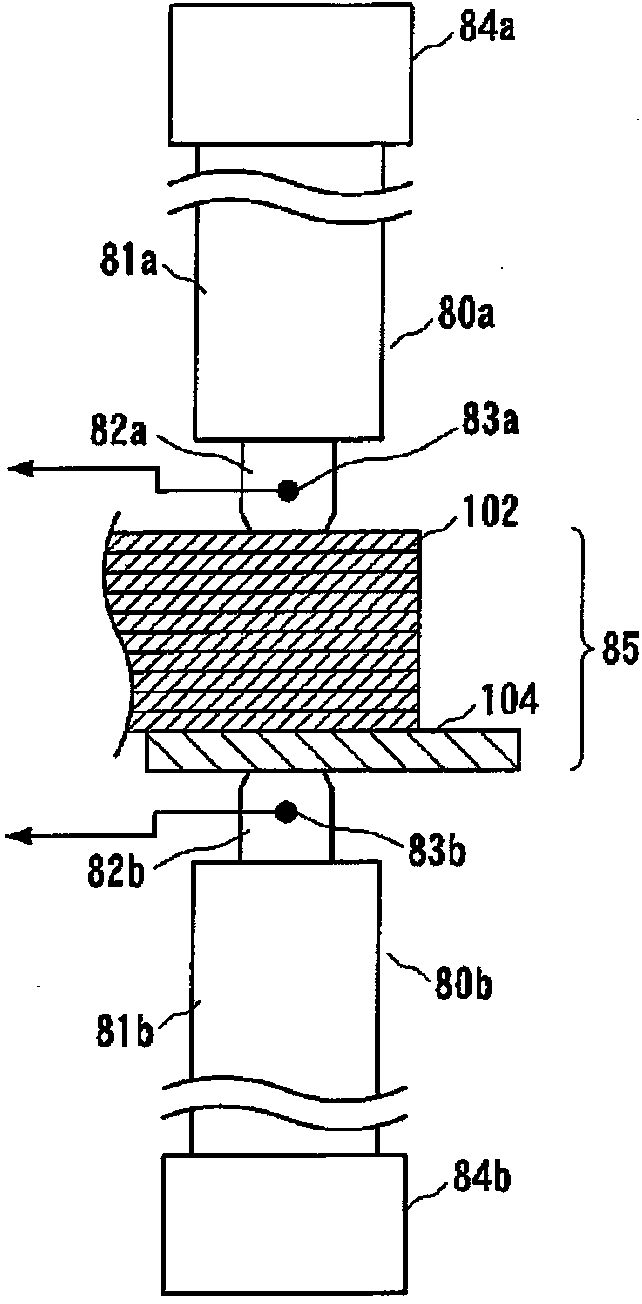

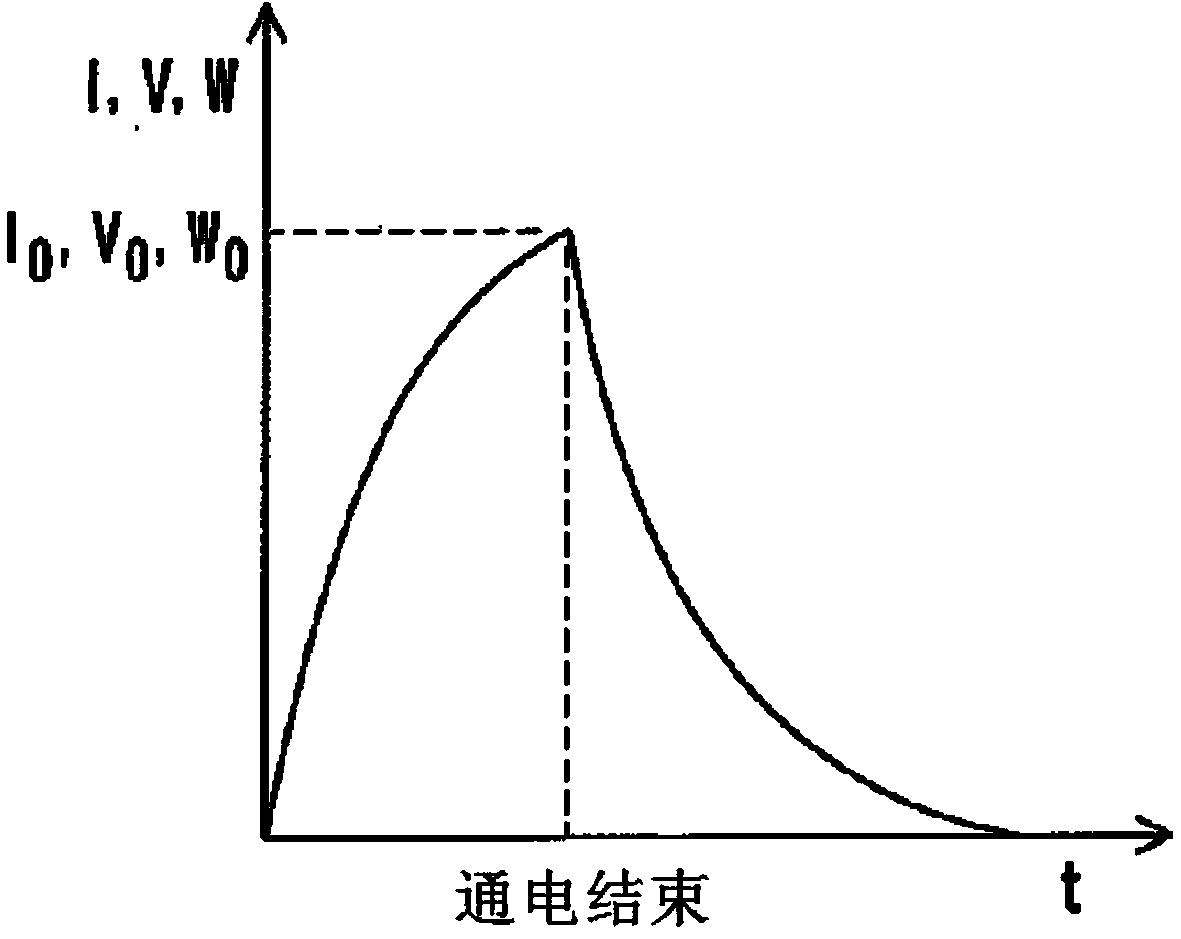

[0044] Next, a second embodiment of the present invention will be described. This embodiment describes an example of more specific control. In this embodiment, the structure of the welding device is the same as that of the first embodiment, so use Figure 1 to Figure 5 The reference signs are used for explanation. Figure 6 It is a flowchart showing the operation of the welding device of this embodiment. In addition, below, the electrodes 80a, 80b will be applied such as image 3 The case of 1 pulse current shown is counted as 1 time.

[0045] First, when the user instructs to start welding, the control unit 16 uses the inter-electrode resistance value R previously set in the storage unit 18 0 Welding with the resistance control method as the end condition value ( Figure 6 step S1). The welding method in the resistance control mode is as described in the first embodiment. At this time, the control unit 16 performs welding in the resistance control mode n times (n is an...

no. 3 Embodiment

[0052]Next, a third embodiment of the present invention will be described. In this embodiment, by changing the structure of the object to be bonded in the first embodiment and the second embodiment, in addition to the effects described in the first embodiment and the second embodiment, the electrode consumption can be suppressed. In this embodiment, the structure of the welding device is also the same as that of the first embodiment and the second embodiment, so use figure 1 , Figure 3 ~ Figure 6 The reference signs are described.

[0053] As described above, in resistance welding, it is possible to suppress generation of metal powder and breakage of tabs, which are problems in ultrasonic welding and laser welding. However, the material to be joined made of Al or Cu has low electrical resistance and does not generate heat easily. Therefore, when a plurality of tabs are to be joined, it is necessary to flow a large current through the electrodes, and there is a problem that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com