Resin covering device

A technology for covering devices and resins, which is applied in the fields of coating liquid devices on the surface, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve the problems of device quality deterioration, cleaning water splashing wafers, etc., and achieve the effect of inhibiting local peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

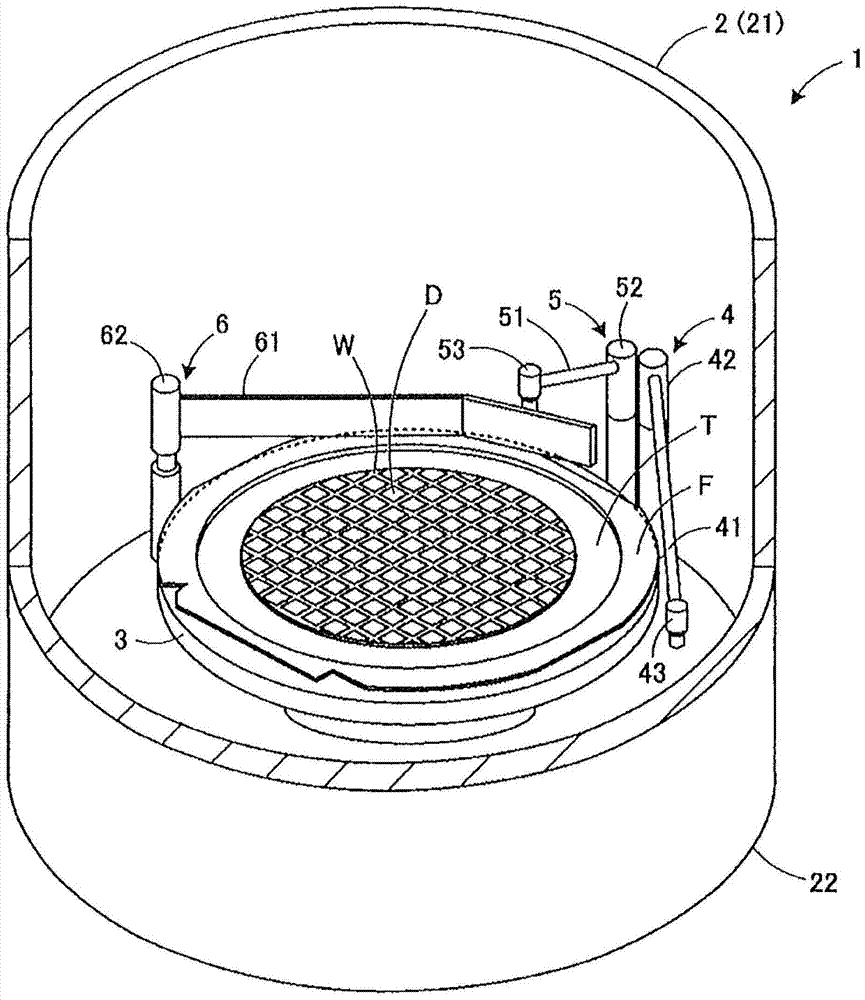

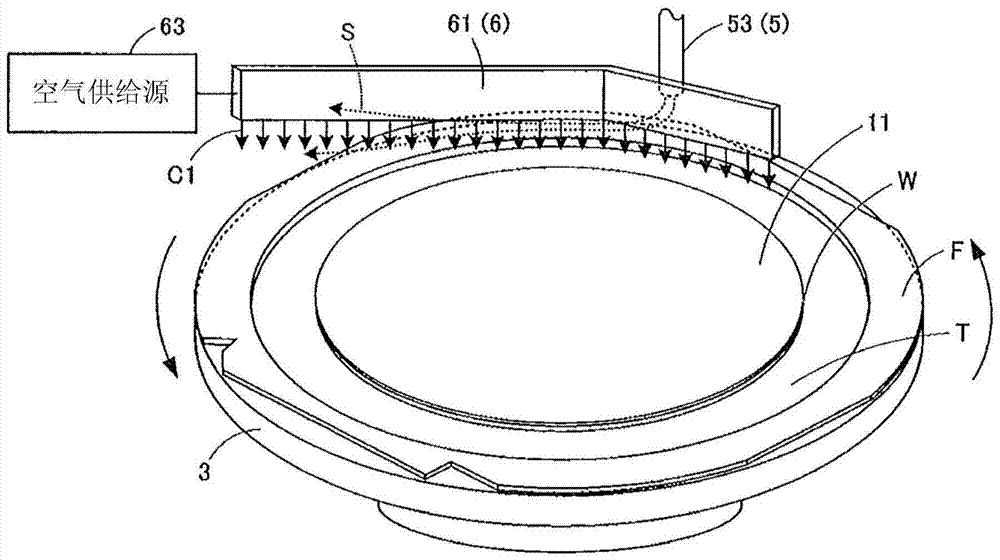

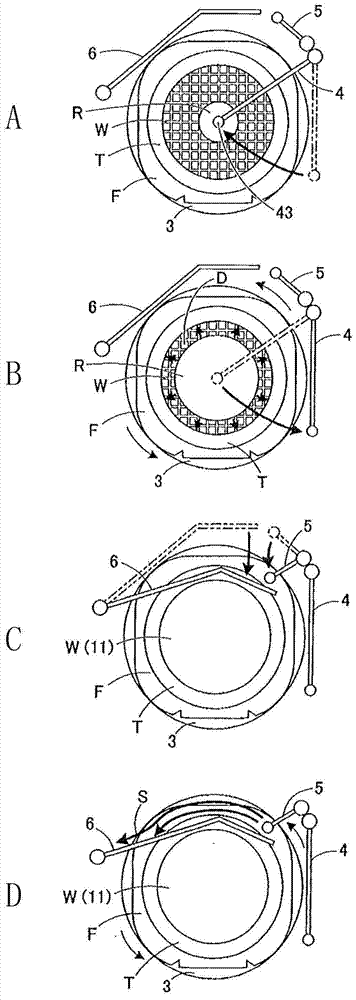

[0039] Hereinafter, the resin coating device of this embodiment will be described with reference to the drawings. figure 1 It is a perspective view of the resin coating device of 1st Embodiment. figure 2 It is a perspective view at the time of frame cleaning of the first embodiment. In addition, the resin covering device of the first embodiment is not limited to figure 1 structure shown. The resin covering device may have any structure as long as it has a structure for cleaning the frame while separating the wafer and the annular frame with the air curtain.

[0040] Such as figure 1 As shown, the resin coating apparatus 1 is configured to perform frame cleaning on the ring-shaped frame F around the wafer W after coating the upper surface of the wafer W with a water-soluble resin by a spin coating method. The wafer W is a semiconductor wafer such as a silicon wafer or gallium arsenide, and is formed in a disc shape. The wafer W is divided into a plurality of regions by la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com