Dry type particle granularity measuring method

A measurement method and particle technology, which is applied in the direction of measurement devices, particle size analysis, particle and sedimentation analysis, etc., can solve the problems of long measurement time, cumbersome operation, and low measurement accuracy, and achieve the effect of avoiding cumbersome measurement process and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The specific process of the dry particle size measurement method in the present embodiment is as follows:

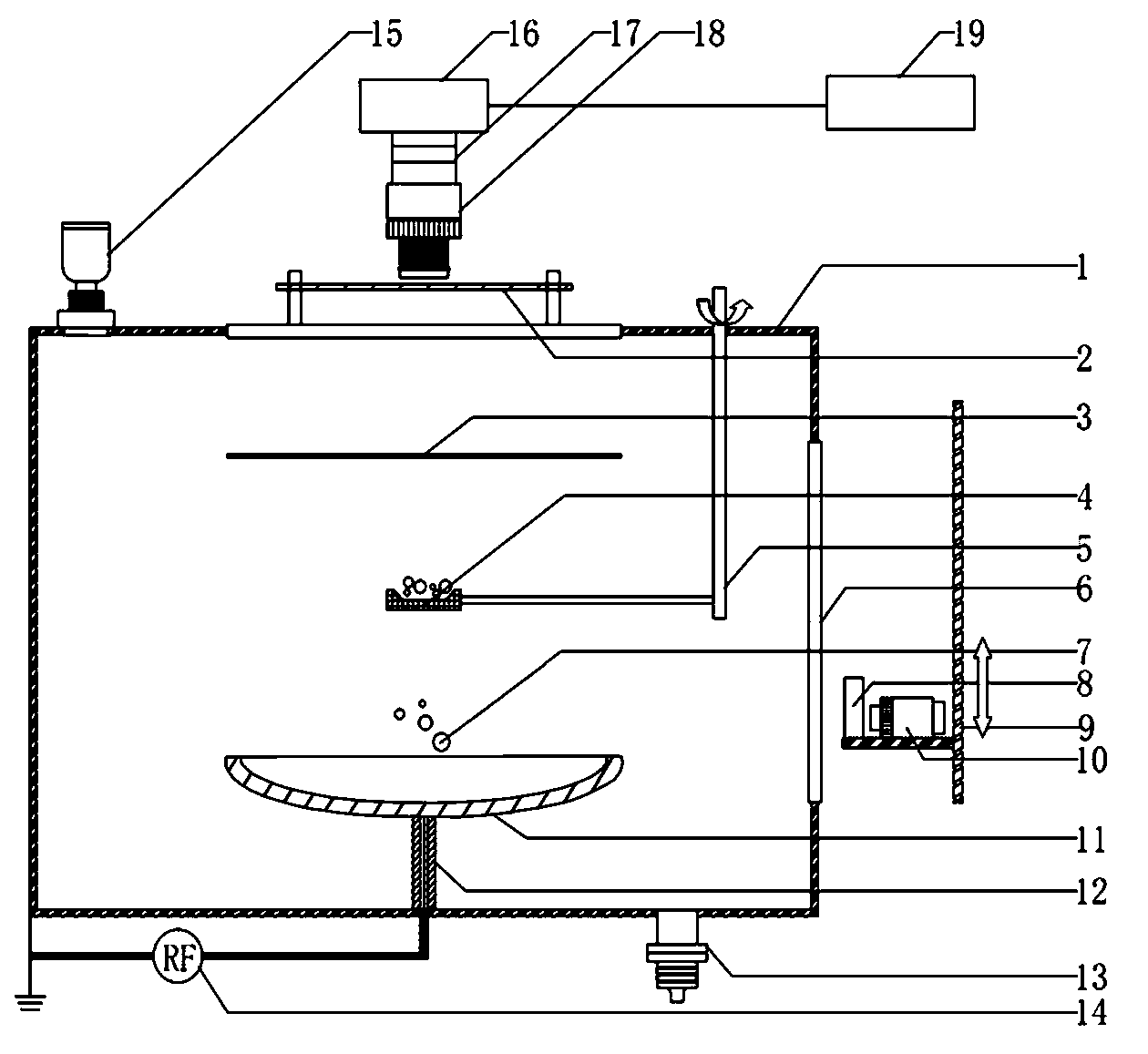

[0040] Step a: Reference figure 1 , first set a vacuum chamber 1, the vacuum chamber 1 is surrounded by a stainless steel cavity, and the stainless steel cavity is grounded; in the vacuum chamber 1, the upper and lower plates are horizontally arranged, the upper plate 3 is grounded, and the lower plate 11 is connected to the radio frequency The power electrode of the power supply 14 and the other electrode of the radio frequency power supply 14 are grounded, and the radio frequency power supply 14 is placed outside the vacuum chamber 1 . When the RF power supply 14 is turned on, the lower plate 11 is negatively charged (or has a negative potential), and uniform plasma can be generated between the upper and lower plates through gas discharge.

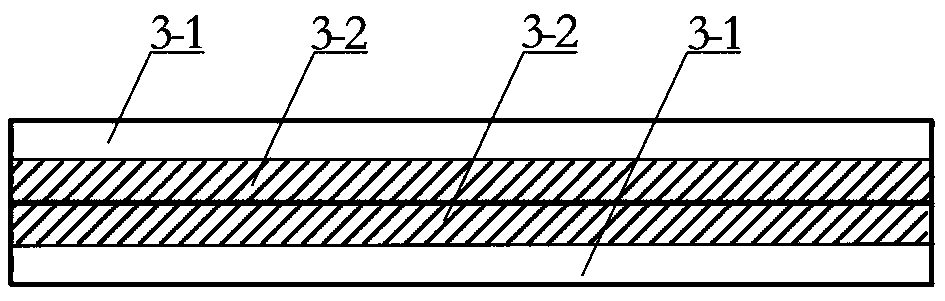

[0041] Such as figure 2 As shown, the upper plate 3 is made up of two pieces of ITO conductive glass, and each piece of...

Embodiment 2

[0065] Compared with embodiment 1, this embodiment has the following differences:

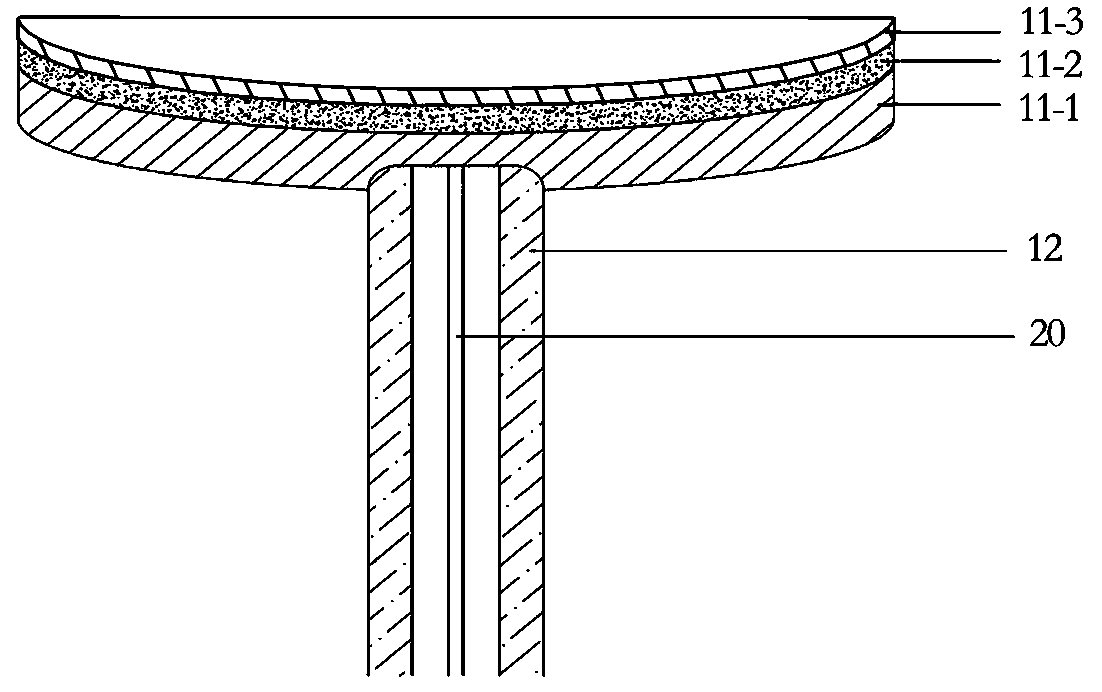

[0066] The power supply in step a of this embodiment is a DC power supply, the lower pole plate is connected to the negative pole of the DC power supply, the positive pole of the DC power supply is grounded, and the DC power supply is placed outside the vacuum chamber; Prevent the particles scattered from the particle pool from falling to the glass ring outside the lower plate. A preferred embodiment is: a frosted layer is formed on the surface of the metal plate through a frosting process, and a blackened layer is formed on the surface of the frosted layer through a blackening process.

[0067] Step d is: turn on the DC power supply, adjust the voltage of the DC power supply to 350V, make the lower plate have a negative potential, and generate uniform plasma between the upper and lower plates through gas discharge under the action of the DC power supply.

[0068] Step f is: turn on the light so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com