Automobile three-way catalytic converter automatic cycle cleaning machine

A three-way catalytic converter and automatic circulation technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problem that cleaning fluid enters the engine cylinder and is not recommended, so as to restore the exhaust gas purification ability and improve the exhaust gas Effects of back pressure and recovery of catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with specific embodiments.

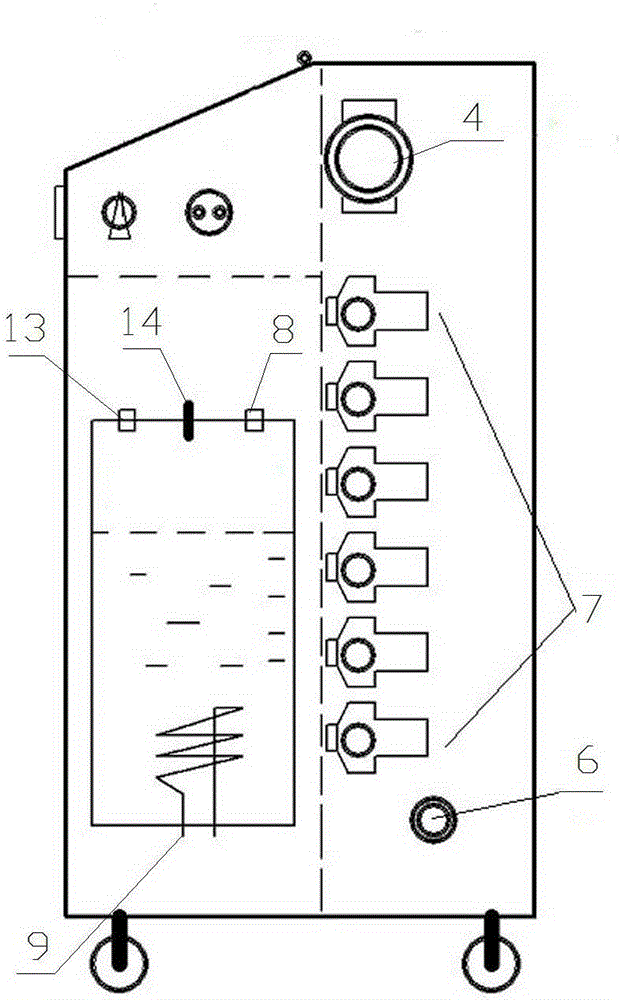

[0037] like Figure 1-5 As shown in the figure, the auto three-way catalytic converter automatic circulation cleaning machine, the case 1 is provided with a batching tank 2, a filter 3 and a circulating pump 4, a water inlet 5 is provided above the case 1 to connect the tap water pipe, and a water outlet 6 is provided below the case 1 and the ingredients The drain pipes on the tank are connected, and the tap water flows into the batching tank 2, the filter 3 and the circulating pump 4 through the pipeline. The top of the batching tank is provided with a feeding door 8, and the lower part of the batching tank is provided with an electric heater 9, which heats the cleaning liquid and automatically maintains a constant temperature, and through the heated cleaning liquid, the entire three-way catalytic converter is They are all in a constant temperature state. Due to the use o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com