Method for upgrading and reusing catalyst fine powder in methanol to olefins reaction

A technology for methanol to olefins and catalysts, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst recovery, waste, active component destruction, etc., achieve catalytic performance recovery, and reduce manufacturing costs. , to achieve the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

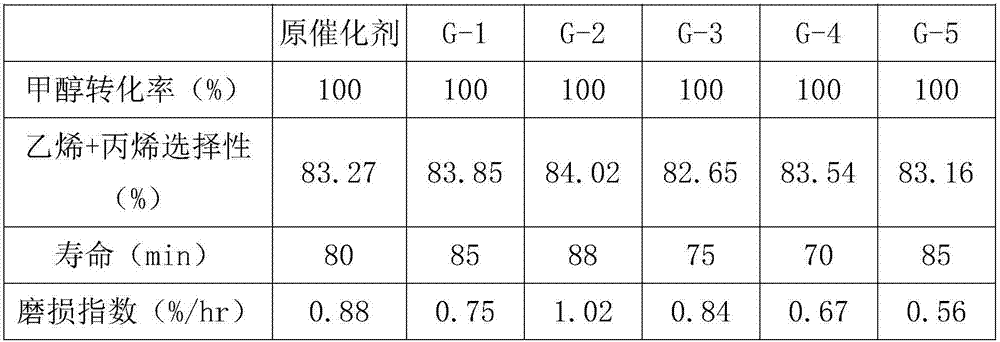

Examples

Embodiment 1

[0023] (1) Weigh 20 grams of catalyst fine powder, and give a particle size distribution of 30 μm for D50, 50 to 80 μm, and 60 μm for D90, (the catalyst fine powder is an industrial sample provided by Ningxia Baofeng Energy Group Co., Ltd., and the catalyst molar ratio is composed of :SiO2 2 :Al 2 o 3 :P 2 o 5 : C=0.5:1.0:0.7:0.11) roasting at 600°C for 1.5 hours;

[0024] (2) Put the calcined catalyst fine powder into a high-pressure crystallization kettle, and add 13 grams of silica sol (SiO 2 Mass fraction 25%), 42 grams of pseudo-boehmite (Al 2 o 3 Mass percent 65%), 75 grams of phosphoric acid (P 2 o 5 61% by mass), 98 grams of triethylamine, 195 grams of deionized water, crystallized at 190°C for 20 hours, centrifuged and washed to obtain the product;

[0025] (3) The resulting product is mixed with 120 grams of deionized water, 65 grams of silica sol (SiO 2 mass fraction 40%), 60 grams of kaolin (water content is 15wt%) mixed to obtain the slurry, after stirri...

Embodiment 2

[0027] (1) Weigh 230 grams of fine catalyst powder (the particle size distribution is 30 μm for D50, and 55 μm for D90, the fine catalyst powder is an industrial sample provided by Ningxia Baofeng Energy Group Company, and the catalyst molar ratio is composed of: SiO 2 :Al 2 o 3 :P 2 o 5 : C=0.1:1.0:0.6:0.12) roasting at 450°C for 5 hours;

[0028] (2) Put the calcined catalyst fine powder into a high-pressure crystallization kettle, and add 4 grams of white carbon black (SiO 2 Mass fraction 92%), 56 grams of pseudo-boehmite (Al 2 o 3 Mass percent 65%), 80 grams of phosphoric acid (P 2 o 5 mass percent 61%), 320 grams of tetraethylammonium hydroxide, 60 grams of deionized water, crystallized at 160° C. for 48 hours, centrifuged and washed to obtain the product;

[0029] (3) the resulting product is mixed with 160 grams of deionized water, 72 grams of aluminum sol (Al 2 o 3 mass percent 21%), 80 grams of kaolin (water content is 15wt%) mixed to obtain the slurry, after ...

Embodiment 3

[0031] (1) Weigh 260 grams of catalyst fine powder (the particle size distribution is 26 μm for D50 and 58 μm for D90, the catalyst fine powder is an industrial sample provided by Ningxia Baofeng Energy Group Company, and the catalyst molar ratio is composed of: SiO 2 :Al 2 o 3 :P 2 o 5 : C=0.3:1.0:0.7:0.09) baked at 500°C for 4 hours;

[0032] (2) Put the calcined catalyst fine powder into the high-pressure crystallization kettle, and add 25 grams of silica sol (SiO 2 Mass fraction 25%), 50 grams of pseudo-boehmite (Al 2 o 3 Mass percent 65%), 65 grams of phosphoric acid (P 2 o 5 mass percent 61%), 110 grams of morpholine, 240 grams of deionized water, crystallized at 200 ° C for 12 hours, centrifuged and washed to obtain the product;

[0033] (3) The resulting product is mixed with 130 grams of deionized water, 85 grams of aluminum sol (Al 2 o 3 mass percent 21%), 56 grams of kaolin (water content is 15wt%) mixed to obtain the slurry, after stirring, grinding, mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com