Clean and environment-friendly straw briquette coal and preparation method thereof

A clean and environmentally friendly, straw-based technology, applied in the petroleum industry, waste fuel, solid fuel, etc., can solve environmental pollution and other problems, and achieve the effects of good air permeability, sufficient combustion, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

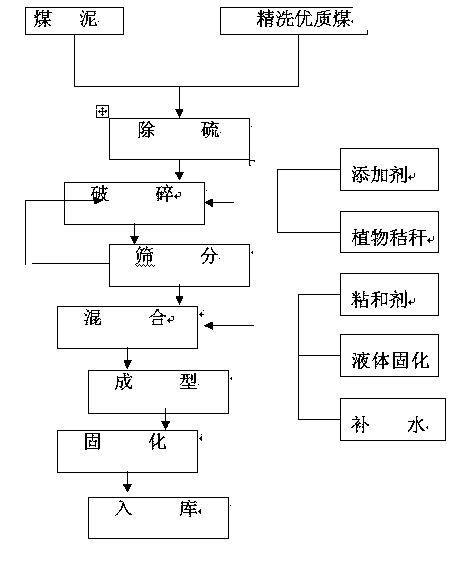

[0022] The present invention will be further explained below in conjunction with the drawings and specific implementations:

[0023] 1. The preparation method of clean and environmentally friendly straw briquette of the present invention includes the following steps:

[0024] 1) Cut the wheat straw into wheat straw grains, crush the corn stalks into corn stalk grains to ensure that the particle size is less than 3 mm, then mix the wheat straw grains and corn stalk grains in a certain ratio, and press the mixed wheat straw and corn stalks into Straw block; the grain length of the wheat straw grains is 1 mm to 3 mm, the grain length of the corn stalk grains is 1 mm to 3 mm, and the mixing ratio of the wheat straw grains and the corn stalk grains is 3:5.

[0025] 2) The coal slime and finely washed coal, gangue, and straw materials are evenly stirred by a mixer and then added with additives for crushing and screening together to ensure that the particle size of coal slime is below 3mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com