Simple preparation method of ruthenium polypyridine complex

A technology of ruthenium chloride hydrate and bipyridyl, which is applied in the field of electrochemistry, can solve the problems of unfavorable industrialized expansion of production, high requirements for reaction vessels, and difficulty in large-scale procurement, etc., and achieves good purification effect, increased overall yield, and improved product purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of ruthenium (II) complex tris (2,2'-bipyridyl) ruthenium (II) chloride hexahydrate of the present invention, the steps are as follows:

[0031] Ruthenium chloride hydrate and 2,2'-bipyridine are dissolved in ethanol and ethylene glycol mixed solvent;

[0032] The reaction was heated, cooled to room temperature, and the ethanol was rotary evaporated;

[0033] Add saturated sodium chloride solution to precipitate a solid, filter, add water to recrystallize, and dry to obtain tris(2,2'-bipyridyl)ruthenium(II) chloride hexahydrate.

[0034] The reaction of the invention is simple and easy to operate, and the overall yield and product purity are greatly improved compared with the existing method. After recovering ethanol in post-treatment, directly add saturated sodium chloride solution, precipitate solid, and obtain crude product by suction filtration, without using any organic solvent, which is greatly simplified compared with the prior art, and is...

Embodiment 1

[0040]A total of 13g (50mmol) of ruthenium chloride hydrate and 39g (250mmol) of 2,2'-bipyridine were added to 2L ethylene glycol and ethanol mixed solution (ethylene glycol 400ml), and the reaction solution was heated to After about 20 minutes at 100°C, the ruthenium chloride hydrate was completely dissolved, reacted for about 7 hours, stopped heating and cooled to room temperature. Distill the reaction liquid under reduced pressure, recover about 1200ml of ethanol, add 1000ml of saturated sodium chloride solution, precipitate a large amount of red solid, filter with suction to obtain 37g of solid, recrystallize with 93ml of water, dry to obtain tris(2,2'-bipyridine) Ruthenium(II) chloride hexahydrate was 35g, and the yield was 94.6%.

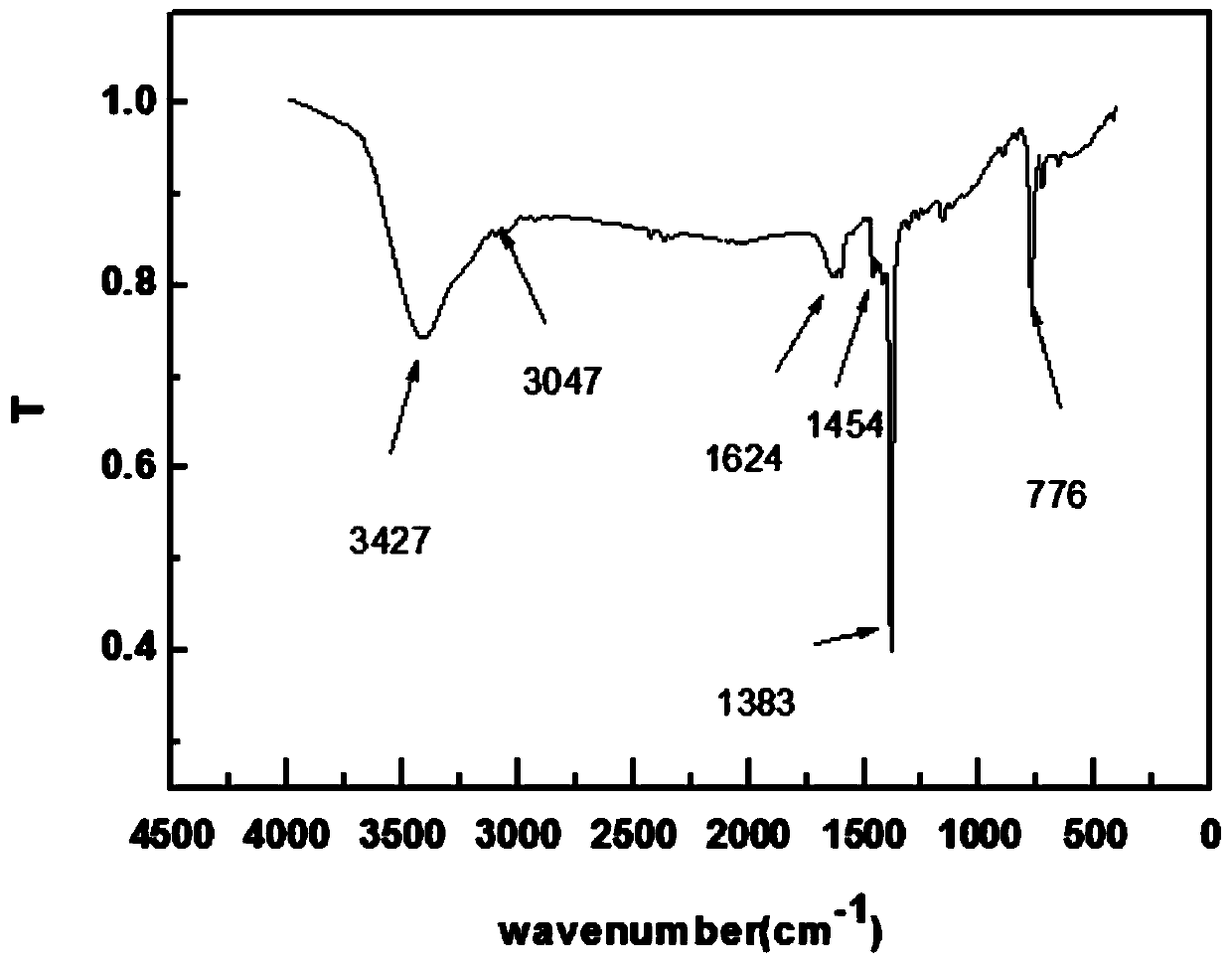

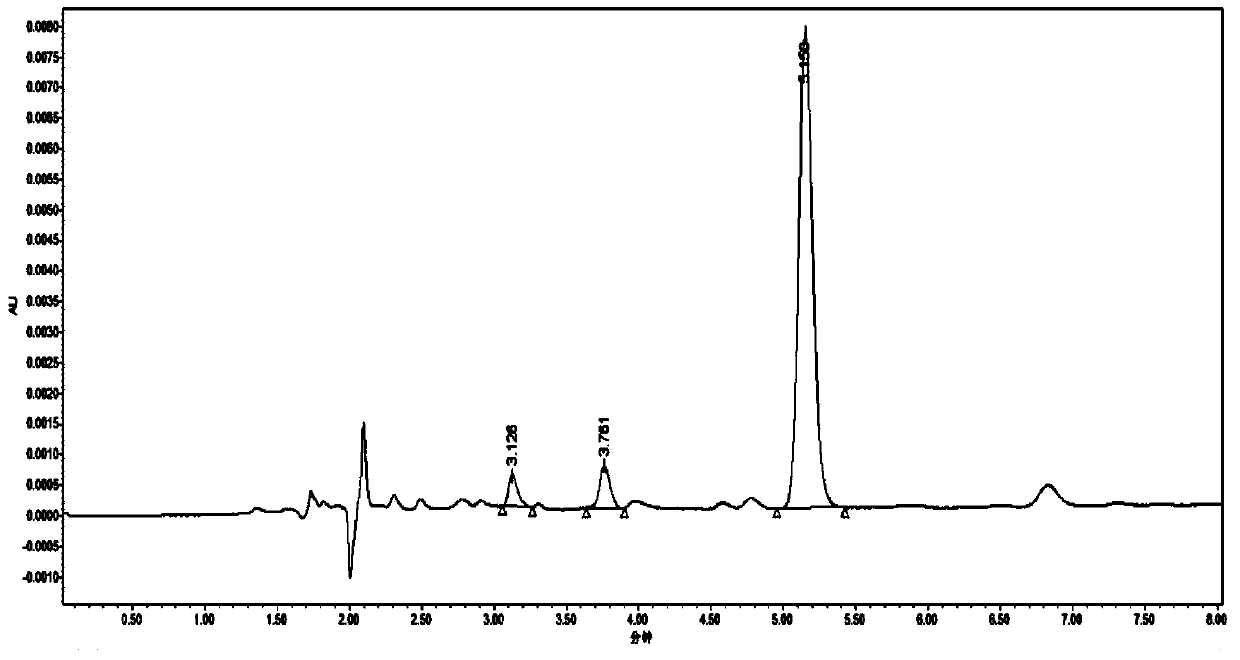

[0041] The infrared absorption spectrum of the product obtained in this embodiment and the purchased J&K brand three (2,2'-bipyridyl) ruthenium (II) chloride hexahydrate (IR spectrum testing instrument: Bruker VECTOR-22, testing condition: KBr...

Embodiment 2

[0048] A total of 26g (100mmol) of ruthenium chloride hydrate and 78g (500mmol) of 2,2'-bipyridine were added to 4L ethylene glycol and ethanol mixed solution (ethylene glycol 1600ml), and the reaction solution was heated to After about 30 minutes at 90°C, the ruthenium chloride hydrate was completely dissolved, reacted for about 9 hours, stopped heating and cooled to room temperature. Distill the reaction liquid under reduced pressure, recover about 2000ml of ethanol, add 2000ml of saturated sodium chloride solution, precipitate a large amount of red solid, and obtain 79g of solid by suction filtration, recrystallize with 158ml of water, dry to obtain tris(2,2'-bipyridine) Ruthenium(II) chloride hexahydrate was 71g, and the yield was 95.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com