Integrated automobile wheel and manufacturing method thereof

A manufacturing method and wheel technology, applied in the direction of wheels, web-type wheels, vehicle parts, etc., can solve the problems of occupying a large workshop area, deteriorating production environment, and inconvenient management, so as to improve the qualified rate of finished products, reduce production management, The effect of reducing the number of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

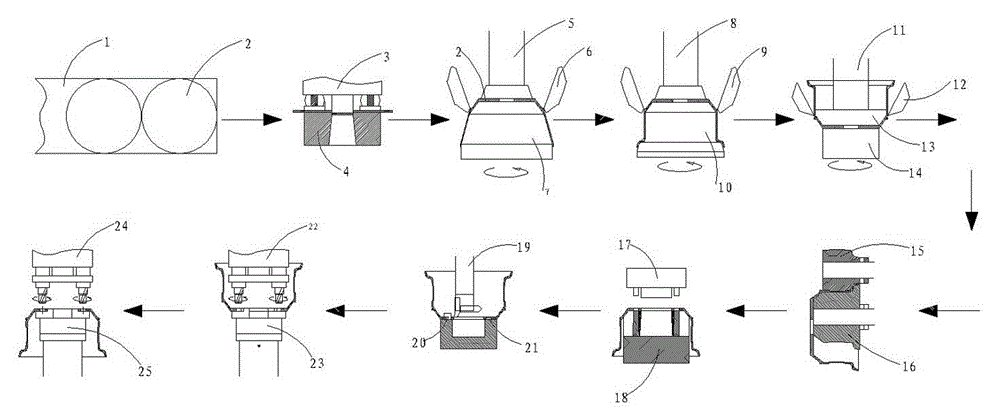

[0023] like figure 1 Shown, a kind of processing method of bimetallic heat sleeve integrated automobile brake drum, its processing steps are:

[0024] In the first step, the steel plate 1 is selected, and the laser cutting machine cuts the circular blank 2 first.

[0025] The second step is to use a sandblasting machine for sandblasting.

[0026] The third step is to use a four-column hydraulic press to punch the center positioning hole. a. The circular blank 2 workpiece is placed on the lower die 4. b. After the center of the outer circle is roughly positioned, the upper die 3 drives the punch down and down. c. The workpiece is punched and centered. hole.

[0027] The fourth step is "coarse spinning" of spinning, a. The workpiece is placed on the mandrel 7, and the center is roughly calibrated. b. The upper press seat 5 goes down to position and compress the workpiece. c. The spindle drives the workpiece to rotate, and the spinning machine Rotary wheel 6 moves and spins. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com