Method for preparing graphene/silver/methionine copper nano-aggregates

A technology of copper methionine and methionine, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve many problems such as the preparation of nano-aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

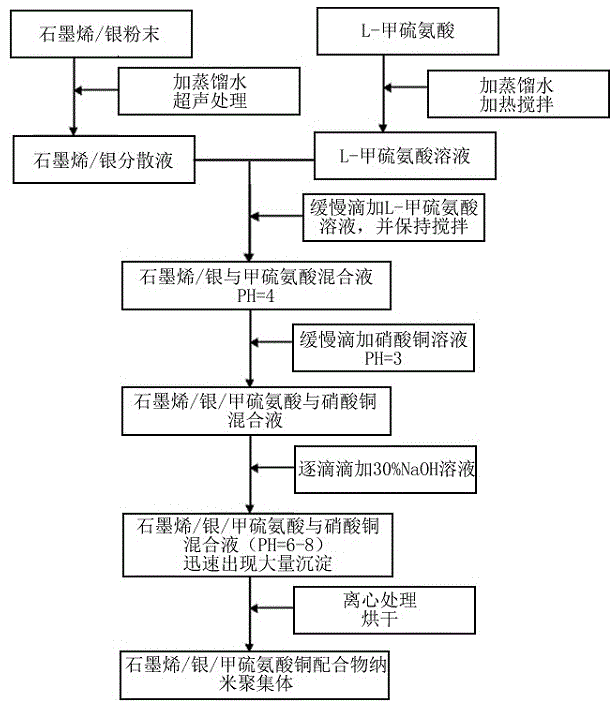

[0031] The process and steps of preparing graphene / silver / copper methionine nano aggregates are as follows:

[0032] A . Graphene / silver powder formulation

[0033] a. Weigh 100 mg of graphite oxide, put it into a 250 ml beaker, add 100 ml of distilled water to prepare graphite oxide suspension;

[0034] b. Discontinuous ultrasonic treatment of the suspension by a low-power ultrasonic cleaner at room temperature to obtain a graphene oxide dispersion;

[0035] c. After standing still, centrifuge the dispersion liquid at a speed of 8000 r / min for 30 min; transfer the upper brown translucent liquid into a clean glass bottle for later use;

[0036] d. Weigh 300 mg of silver nitrate, dissolve in 20 ml of distilled water, add the solution dropwise to the above-mentioned graphene oxide dispersion, and stir;

[0037] e. Pipette 0.02 ml of hydrazine hydrate solution (50%) in 10 ml of distilled water, then slowly add it dropwise to the above-mentioned graphene oxide silver nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com