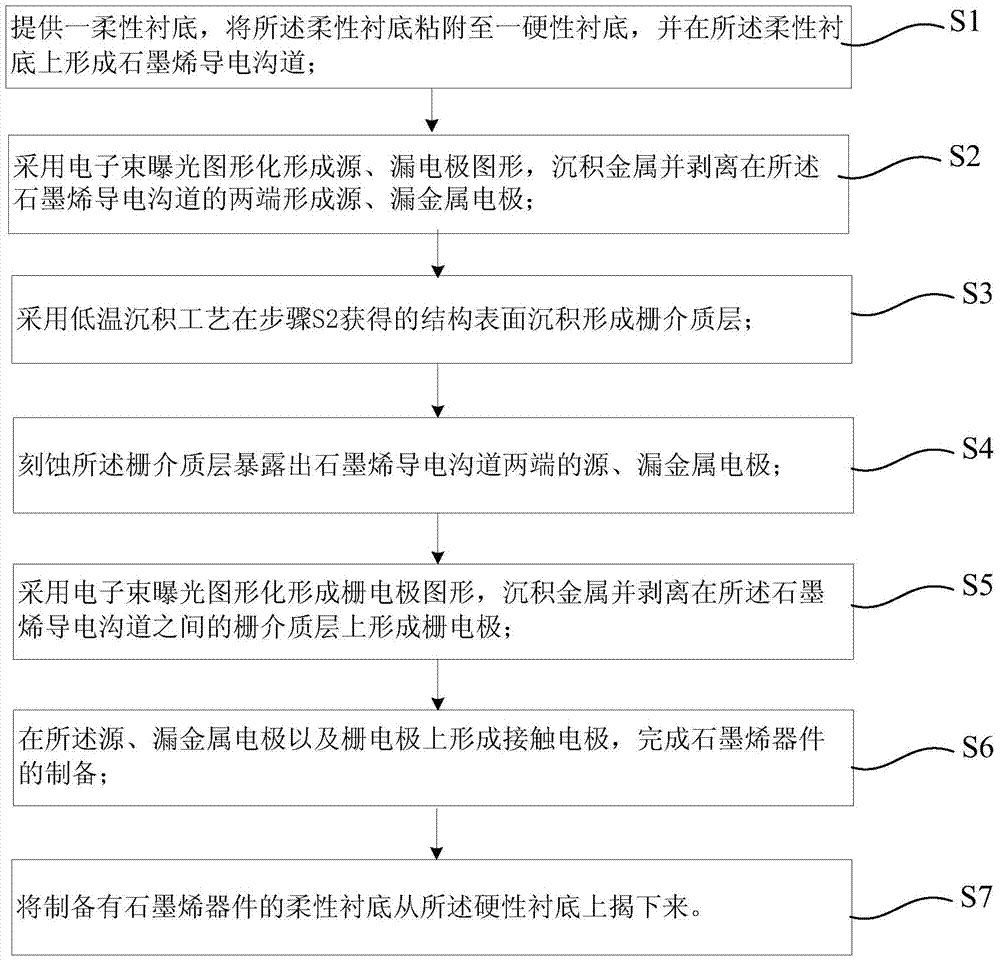

Method for preparing graphene device on flexible substrate

A flexible substrate, graphene technology, applied in the field of microelectronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0068] A double-layer e-beam photoresist is then coated on the substrate. The specific implementation is as follows: the upper surface of the flexible substrate 1 is spin-coated with PMMA1 type electron beam photoresist 2 (such as 495A5) by an automatic glue leveler, and the automatic glue leveler rotating speed is set to 500rpm at a slow speed first, and the time is 10s or so, and then fast 4000rpm, the time is about 45s, and then it can be dried at a temperature of about 180°C. Then spin-coat PMMA2 type electron beam photoresist 3 (such as 950A2), the speed is set to slow at 500rpm, the time is about 10s, and then fast at 4000rpm, the time is about 45s, and then the temperature is about 180 ℃ for drying . The obtained structure diagram is as follows figure 2 shown.

[0069] The electron beam photoresists PMMA1 and PMMA2 used are small molecular weight photoresists and large molecular weight photoresists respectively. After electron beam exposure photoresists, the long ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com