A small transformer oil absorber with filtering function

A technology of transformer oil and oil absorber, which is applied in the direction of transformer/inductor cooling, filtration and separation, chemical instruments and methods, etc. It can solve the problems of inconvenient operation of large-scale oil pumping and oil filtering equipment, surrounding environmental pollution, etc., and achieve guaranteed use value , Guaranteed sealing performance, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

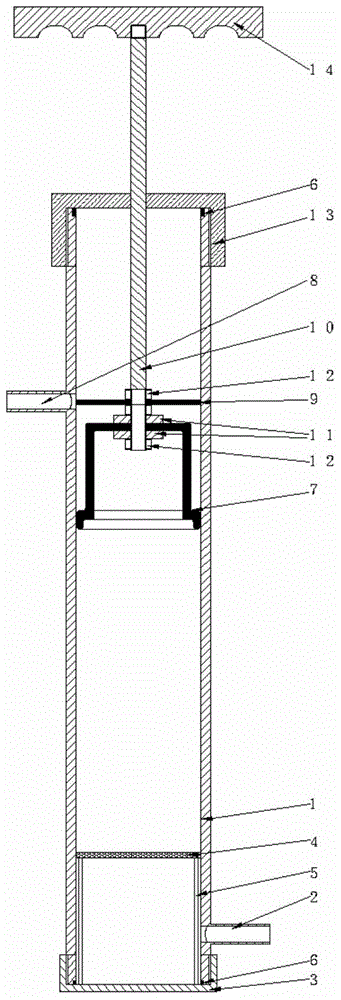

[0025] Such as figure 1 As shown, a small transformer oil absorber with filtering function is mainly composed of an oil absorber cylinder 1, an oil inlet 2, and an oil outlet 8. The upper part of the oil absorber cylinder 1 is provided with a top cover 13, so The lower part of the oil absorber cylinder 1 is provided with a bottom cover 3, and the lower part of the oil absorber cylinder 1 is provided with an oil filter 4, the oil filter 4 is located above the oil inlet 2, and the oil absorber cylinder 1 A central shaft 10 is installed inside, the upper end of the central shaft 10 runs through the middle of the top cover 13 , and the lower end of the central shaft 10 is connected with a rubber cup 7 . The worker connects the oil inlet 2 to the oil pipe, and pulls the center shaft upwards, so that the oil can be sucked into the oil absorber cylinder 1. When the oil enters the oil absorber cylinder 1, it will pass through the oil filter 4 during the upward suction process. , so t...

Embodiment 2

[0027] In order to better realize the present invention, it is convenient to fix the rubber cup 7. In this embodiment, on the basis of Embodiment 1, the upper and lower sides of the rubber cup 7 are provided with fixed rings 11, and the fixed rings 11 are fixed by bolts. 12 is fixed on the axis 10. By using the fixing ring 11 and the bolt 12 to fix the rubber cup 7, the rubber cup can be prevented from moving up and down along the central axis 10, and the bolt 12 and the fixing ring 11 can seal between the rubber cup 7 and the central shaft 10, Prevent air leakage, which affects oil absorption efficiency. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0029] In order to better realize the present invention and improve the sealing performance of the rubber cup 7, in this embodiment, on the basis of Embodiment 2, a sealing horizontal plate 9 is arranged on the upper part of the fixing ring 11, and the sealing horizontal plate 9 passes through The bolt 12 is fixed on the central shaft 10 . By adopting the sealing horizontal plate 9 to seal the rubber cup 7, air leakage can be prevented and the oil absorption efficiency can be improved. Other parts of this embodiment are the same as those of Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com