Heavy water nuclear reactor nuclear power plant nuclear fuel channel end face lead shielding block and preparation method

A technology for nuclear reactors and fuel passages, applied in reactors, shielding, chemical instruments and methods, etc., can solve problems such as the anti-aging performance cannot meet the requirements, the suspension is difficult, and the workload of end shielding projects is increased, so as to achieve good environmental adaptability and Long-term stability, better radiation protection and shielding, effects that promote convenience and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

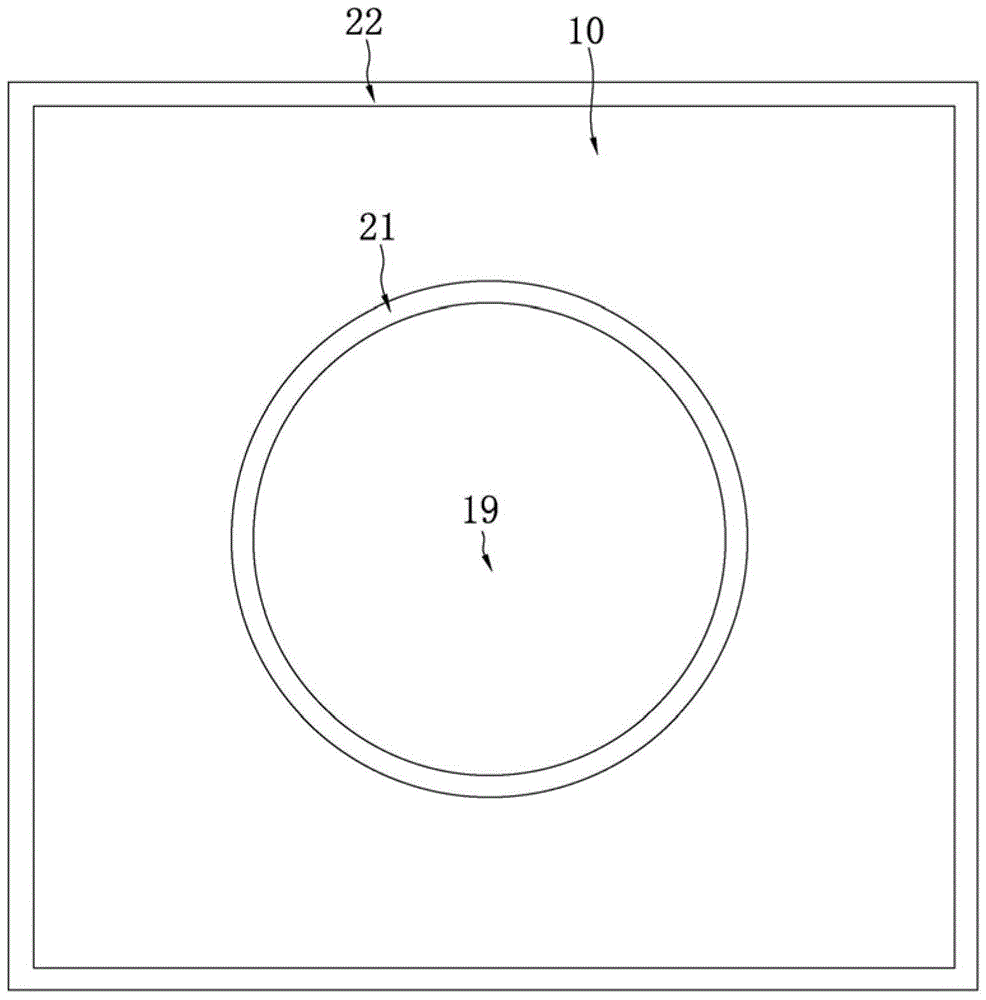

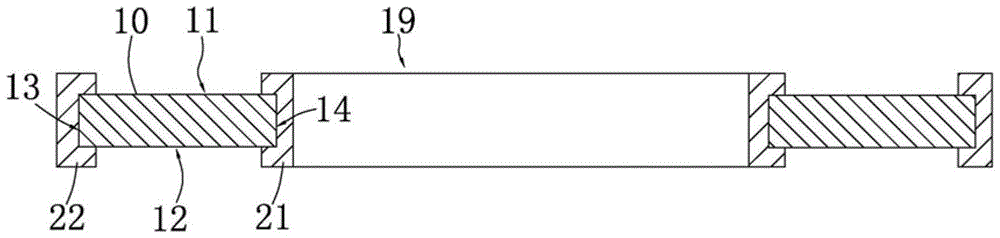

[0073] Such as figure 1 , figure 2 As shown, the lead shielding block on the end face of the nuclear fuel channel of the heavy water nuclear reactor nuclear power plant in this embodiment includes a multi-layer laminated lead foil 10, and the multi-layer laminated lead foil 10 is provided with positioning holes 19 for sheathing the lead shield block on the fuel channel. Silicone rubber layers 21 and 22 are provided on the outer side 13 of the multi-layer laminated lead foil 10 and the inner wall surface 14 of the positioning hole 19 . That is, the upper surface 11 and the lower surface 12 of the multi-layer laminated lead foil 10 are covered with a silicone rubber layer except for a part of the surface at the junction with the outer edge 13 and the inner wall surface 14 of the positioning hole 19, and most of the other surfaces are covered with a silicone rubber layer. Package covered. The silicon rubber layer of this embodiment is partially wrapped to cover important parts...

Embodiment 2

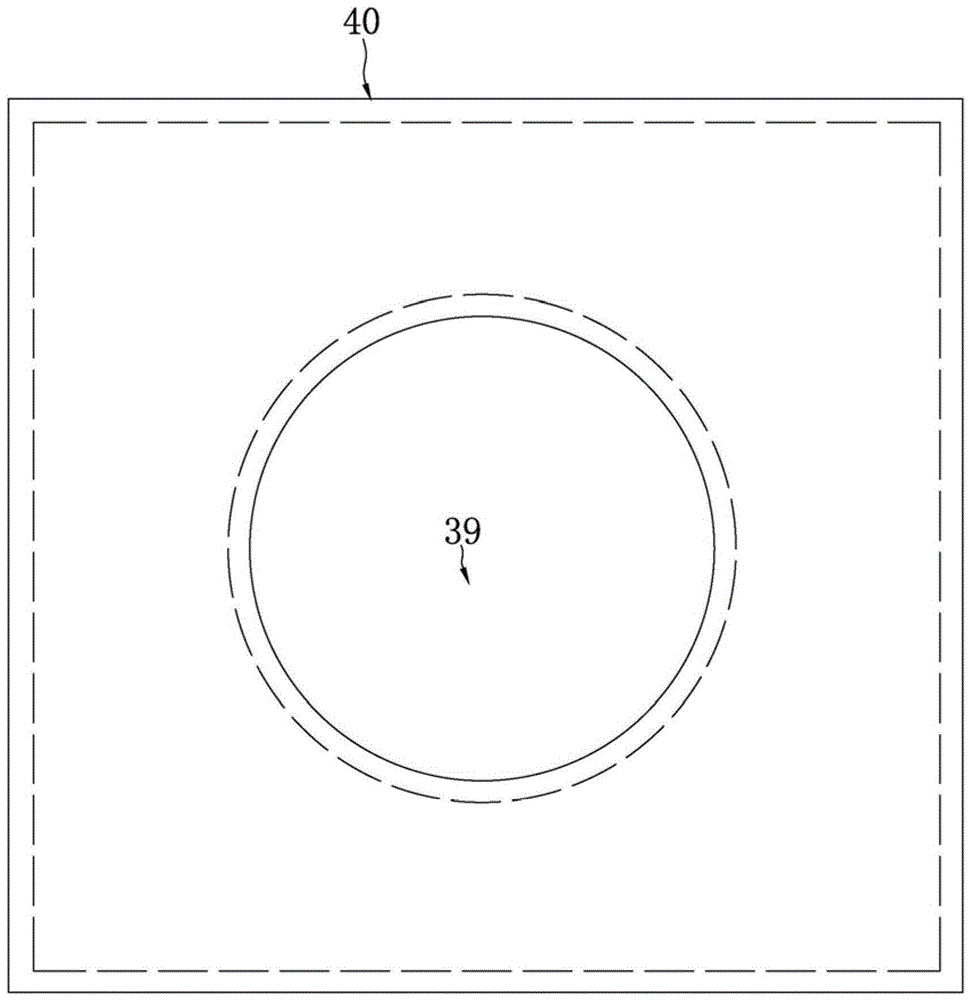

[0083] Such as image 3 , Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the silicone rubber layer of this embodiment adopts the "full wrapping" method, and the outer surface of the multi-layer laminated lead foil 30 is wrapped and covered by molding and / or bonding. All silicone rubber layers 40. That is, the exposed surfaces of the multilayer laminated lead foils are all covered by the silicone rubber layer, including the upper surface 31 of the uppermost lead foil, the lower surface 32 of the lowermost lead foil, the outer peripheral side 33 of the multilayer laminated lead foil, and the positioning holes The inner wall surface 34 of 39 is covered with a silicone rubber layer 40 . Provide comprehensive protection for multi-layer laminated lead foil, while strengthening the strength of the shielding block, it can also strengthen the integrity and return of the lead shielding block. For the preparation / manufacturing method of this embodi...

preparation example 1

[0087] Preparation Example 1: Preparation of multi-layer laminated lead foil

[0088] (1.1) Purification of lead

[0089] Heat the raw lead to 330°C, then raise the temperature to 370°C at a rate of 3°C / min to melt it, keep stirring during this period, and use a scraper to remove impurities floating on the upper part of the lead liquid until there are no floating objects.

[0090] (1.2) Lead casting

[0091] The lead liquid in step (1.1) was poured into the mold and cooled naturally to obtain a lead plate with a thickness of 1 cm.

[0092] (1.3) Lead plate cold rolling

[0093] Using cold rolling equipment, the lead plate in step (1.2) is repeatedly rolled at normal temperature until it is uniform and compact without air bubbles, to obtain a lead foil with a thickness of 0.1 mm;

[0094] (1.4) Lead foil overlay

[0095] Cut the lead foil of step (1.3) into the same size and cut a positioning hole of the same size in the center, and then stack them to obtain multi-layer sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com