Method for monitoring thermal resistance of heat-exchange equipment

A technology of heat exchange equipment and thermal resistance, which is applied in the field of thermal resistance monitoring of heat exchange equipment, can solve the problems of thermal resistance monitoring, fouling monitoring technology backwardness, and slow progress in the research of scale inhibition evaluation methods, and achieve the effect of accurate monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

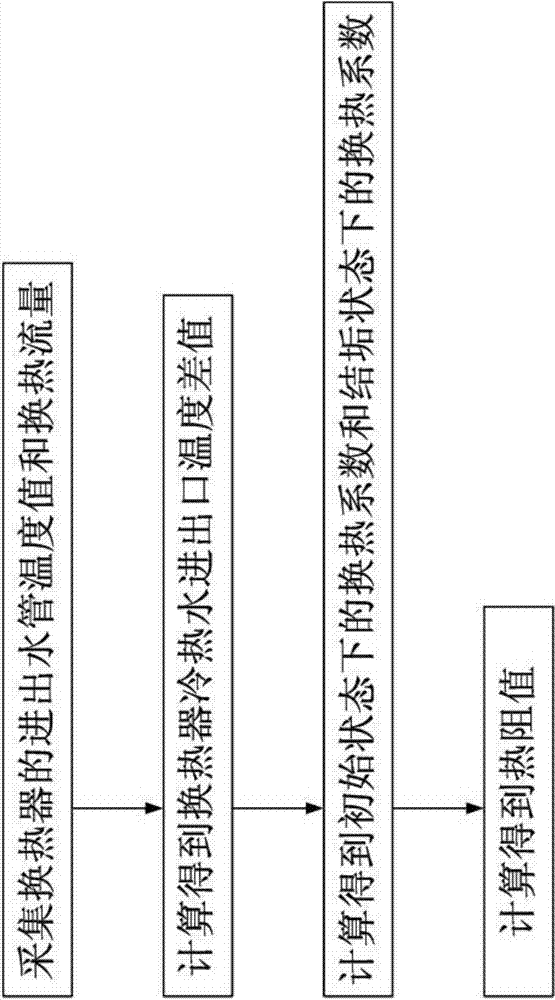

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

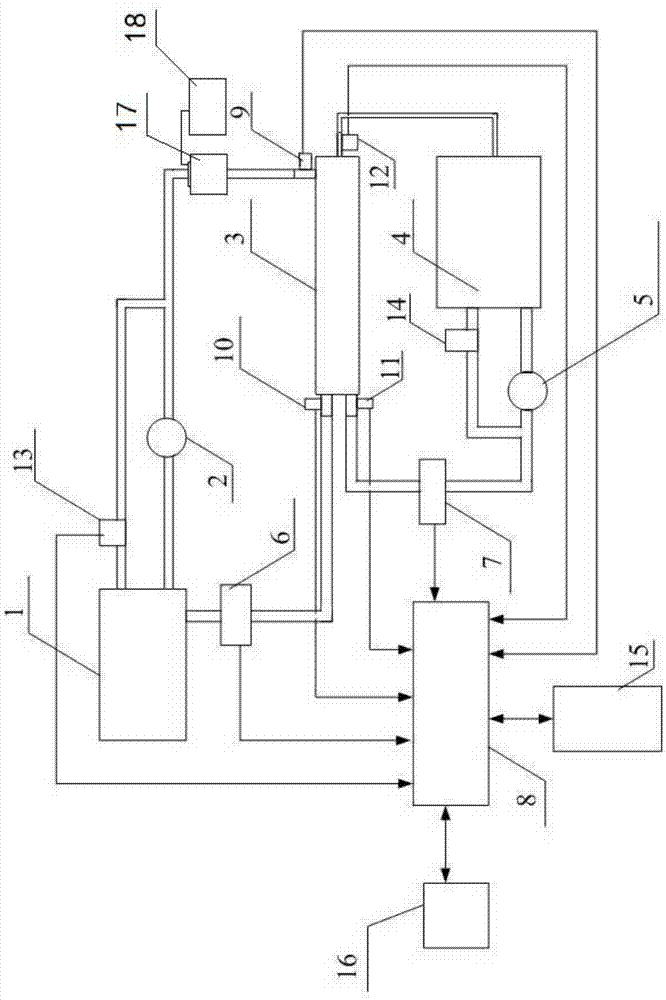

[0021] Such as figure 1 As shown, the heat exchange equipment targeted in this embodiment is a circulating cooling water system, which includes a low-temperature constant temperature water tank 1, a cold water pump 2, a casing heat exchanger 3, a hot water tank 4, and a hot water pump 5. First flowmeter 6, second flowmeter 7, processor 8, first temperature sensor 9, second temperature sensor 10, third temperature sensor 11, fourth temperature sensor 12, water treatment chamber 17 and high frequency signal Generator 18.

[0022] The outlet end of the low-temperature and constant-temperature water tank 1 is connected to the inlet of the cold water pump 2, the outlet of the cold water pump 2 passes through the inlet of the water treatment chamber 17, and the outlet of the water treatment chamber 17 is connected to the casing heat exchanger through a pipeline 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com