In-situ analysis method for accurate determination of billet shell thickness by nail shot

An in-situ analysis and casting slab technology, which is applied in the field of accurately judging the boundary between the solid phase area of the continuous casting slab and the area of different liquid phase ratios in the two-phase area, can solve the problems of difficult quantitative analysis, difficulty in obtaining the boundary of the slab, and high cost question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

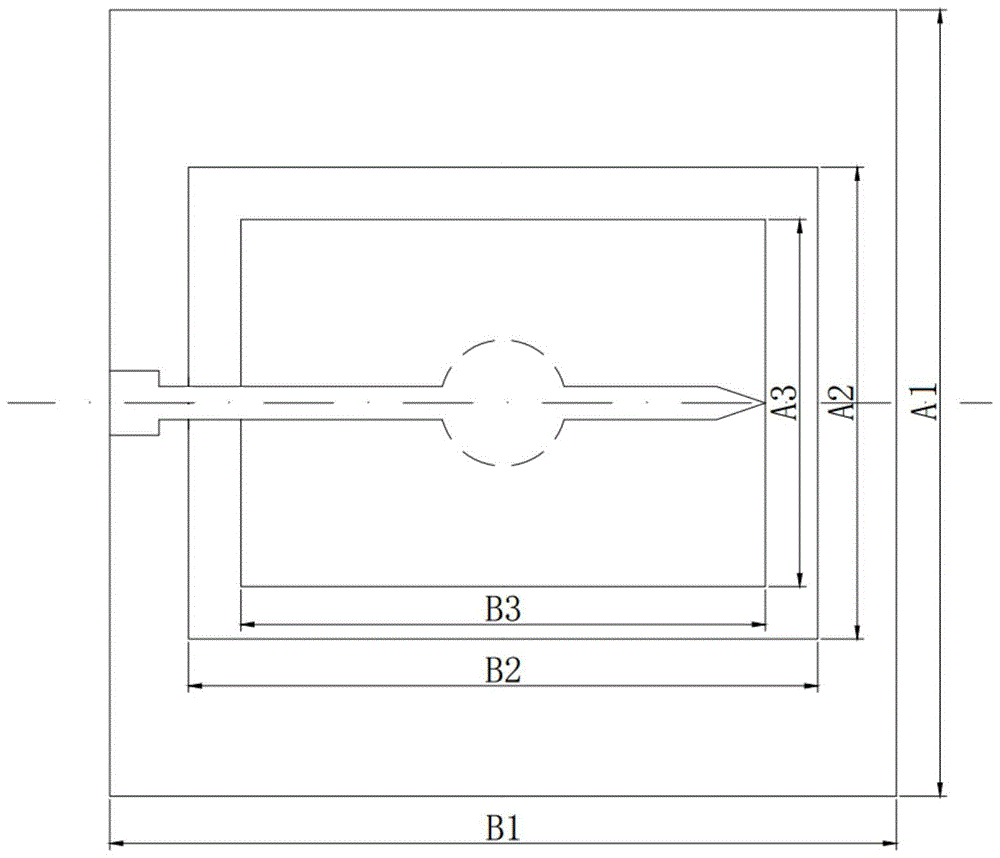

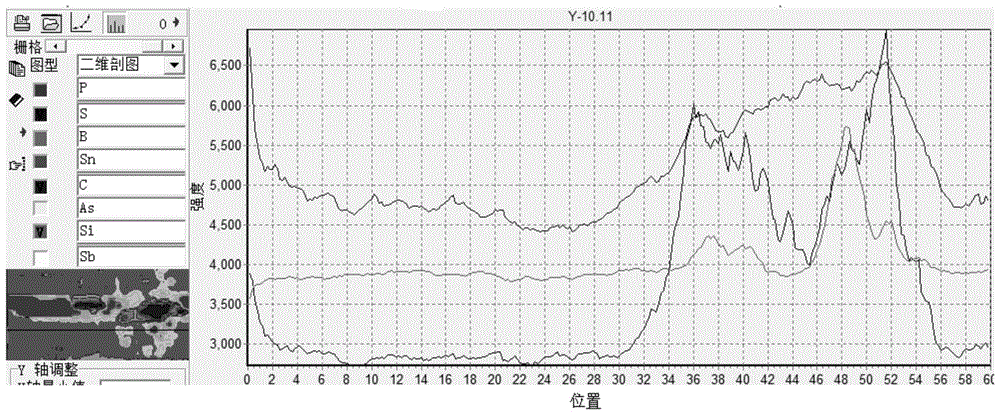

[0028] The technical scheme of the invention is adopted to analyze a certain slab CSG610 steel sample. figure 1 It is a schematic diagram of the position of the in-situ sample and the scanning area in the low-magnification sample, where the size of the low-magnification sample is A1×B1; the size of the in-situ sample is A2×B2; the OPA scanning area is A3×B3; the central circle The inside of the dotted line is the melting part of the nail. Firstly, nailing is performed at the center of the billet width at a distance of 18.0 m from the mold meniscus. The thickness of the billet is 250 mm, the length of the nail body is 140 mm, and the diameter of the nail body is 5 mm. Cut the nail sample from the slab, and the center axis of the nail body basically coincides with the center axis of the low-magnification sample. Use a planer to machine the nailed sample, expose the central axis of the nail body and then polish it to make a low-magnification sample and pickle it to obtain a l...

Embodiment 2

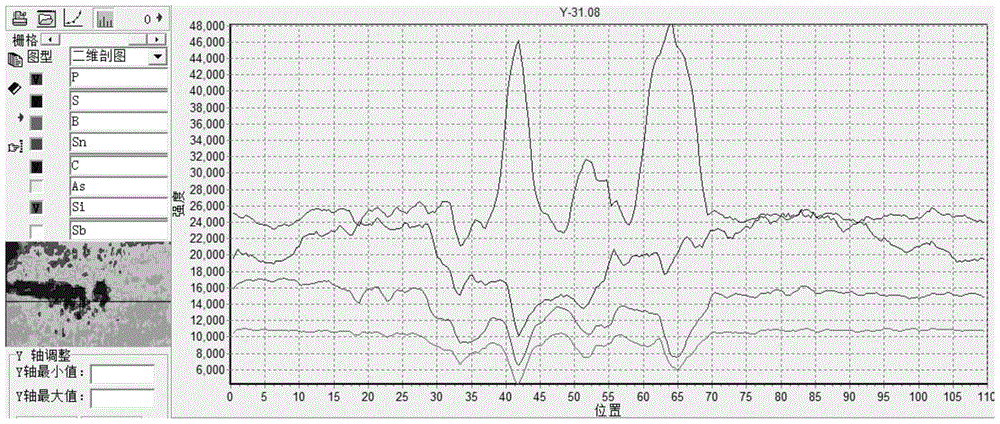

[0031] Adopting the technical solution of the present invention, a 150 mm×150 mm billet 20Cr steel sample is analyzed. Firstly, the nail is shot at the center of the billet width 10.3 m away from the meniscus of the crystallizer, the length of the nail body is 120 mm, and the diameter of the nail body is 5 mm. Cut the nail sample from the slab, and the center axis of the nail body basically coincides with the center axis of the low-magnification sample. Use a lathe to machine the nailed sample, expose the central axis of the nail body and polish it, make and process low-magnification samples with length, width, and thickness of 150 mm, 150 mm, and 25 mm, respectively, and pickle. Get a low magnification photo. Then the low-magnification sample was further processed into an in-situ analysis block sample of 120 mm×90 mm×25 mm. After removing the oil stains on the surface, the nailing surface of the sample was polished with 6# sandpaper to make the surface smooth and clean with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com