Four-slope pinnacle steel structure glass pavilion and manufacturing method thereof

A manufacturing method and technology of spires, applied to building structures, roofs, building components, etc., can solve problems such as unsightly structures, difficult welding, large errors, etc., and achieve the effect of simple lines, reduced construction difficulty, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

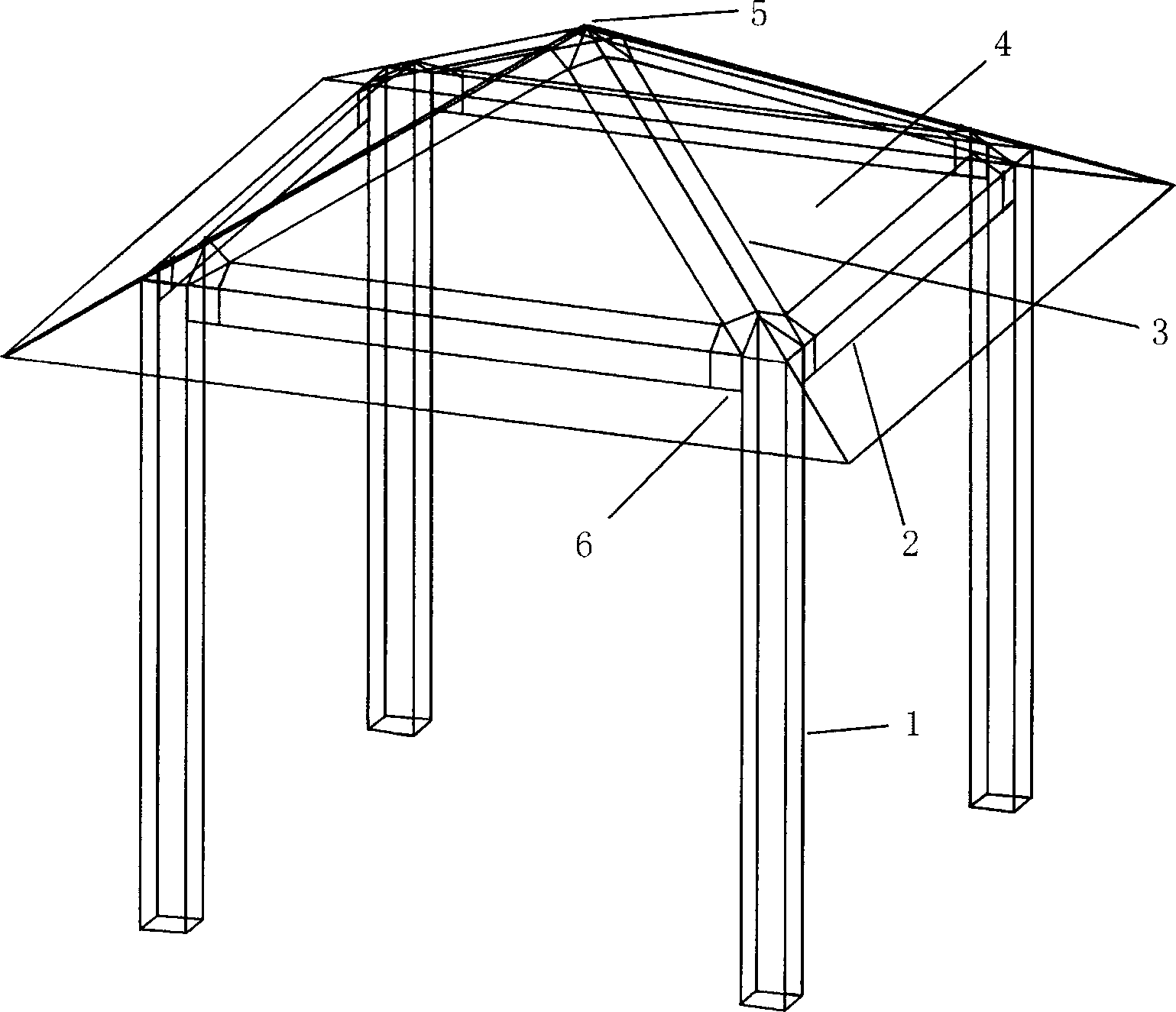

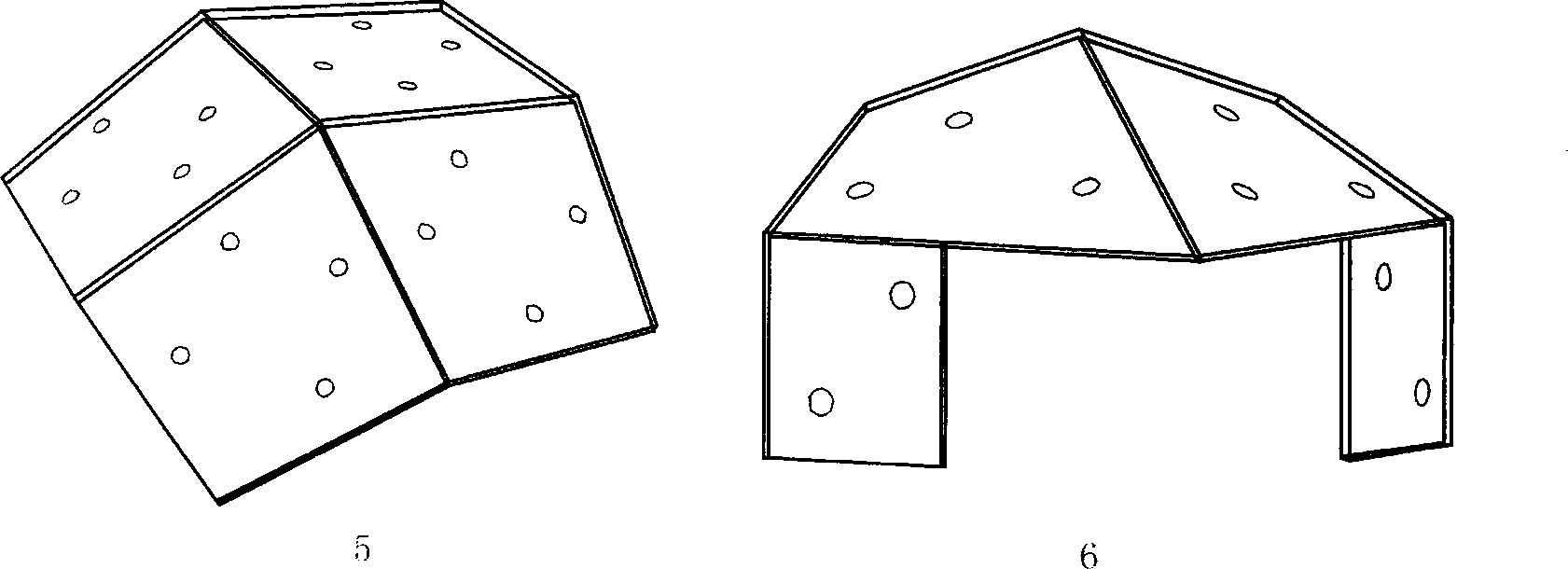

[0015] figure 1 It is an embodiment of the present invention, its structure adopts steel structure, and the enclosure of four slopes adopts colored glaze tempered laminated glass (4). The steel structure is mainly composed of columns (1), flat beams (2) and inclined beams (3). The column is 3m high and made of 200mm x 200mm square steel pipe. Steel folded plate members (6) are welded on the tops of the four columns, and round holes are arranged on the steel members. The four flat beams and the four inclined beams are all made of 300mm wide steel folded plates. The length of the flat beam is 2.4m, and the bending angle is about 120°; The end is cut into a certain shape and round holes are arranged to facilitate the connection with the column with bolts. Four oblique beams intersect at the top of the pavilion and are connected by bolts through steel fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com