Spunlaced non-woven material with one-way water guide function and preparing method and application thereof

A non-woven material, spunlace technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of environmental pollution, different processing technology, complex processing of unidirectional water-conducting non-woven materials, etc., to achieve fast production speed and simple process. , the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

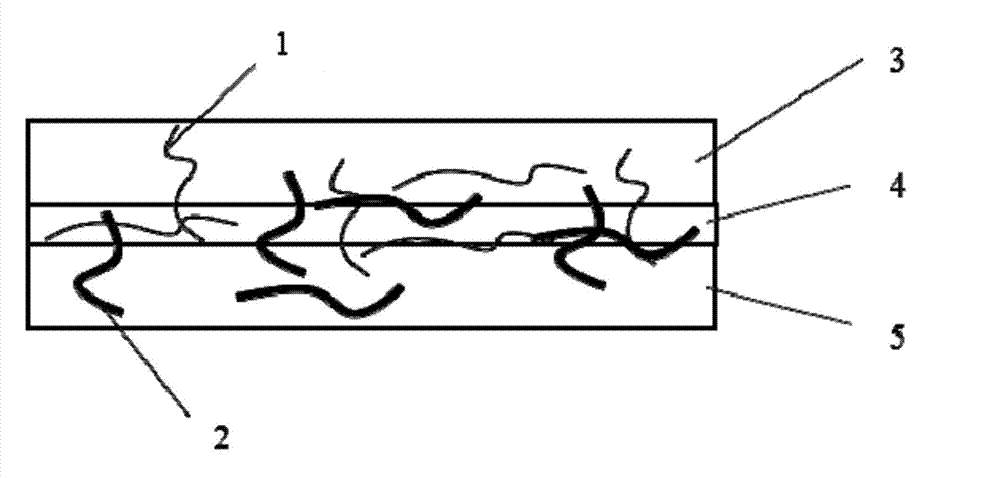

[0042] Hydrophilic viscose fiber is selected, and the surface density of the fiber web is 50g / m 2 ; Hydrophobic chitosan fiber is selected, and the surface density of the fiber net is 40g / m 2 . The two carded fiber webs are composited and then fed to the spunlace machine for one pre-spunlace and two main spunlaces.

[0043] (1) Preparation of fibers used

[0044] Prepare appropriate amount of viscose and chitosan fibers, weigh the fibers of corresponding quality according to the required fiber web surface density, in order to improve the carding quality, loosen the fibers by hand pulling, and spray water on the chitosan fibers for humidification.

[0045] (2) Carding of fiber web

[0046] The fiber prepared in step (1) is fed into a carding machine for carding, and the fiber web is output after carding.

[0047] The surface density of the viscose fiber web is 50g / m 2 , the surface density of chitosan fiber net is 40g / m 2 .

[0048] The fiber webs of the two fibers are h...

Embodiment 2

[0054] Hydrophilic viscose fiber is selected, and the surface density of the fiber web is 50g / m 2 ; Hydrophobic chitosan fiber is selected, and the surface density of the fiber net is 40g / m 2 . The chitosan fiber net is subjected to one pre-spunlace and two main spunlaces, and after drying, it is compounded with the viscose fiber net, and then one pre-spunlace and two main spunlaces are performed after compounding.

[0055] (1) Preparation of fibers used

[0056] Prepare appropriate amount of viscose and chitosan fibers, weigh the fibers of corresponding quality according to the required fiber web surface density, in order to improve the carding quality, loosen the fibers by hand pulling, and spray water on the chitosan fibers for humidification.

[0057] (2) Carding of fiber web

[0058] The fiber prepared in step (1) is fed into a carding machine for carding, and the fiber web is output after carding.

[0059] The surface density of the viscose fiber web is 50g / m 2 , th...

Embodiment 3

[0068] Hydrophilic viscose fiber is selected, and the surface density of the fiber web is 50g / m 2 ; Hydrophobic chitosan fiber is selected, and the surface density of the fiber net is 40g / m 2 . The viscose fiber web is subjected to one pre-spunlace and two main spunlaces, and after drying, it is compounded with the chitosan fiber web, and then one pre-spunlace and two main spunlaces are performed after the compounding.

[0069] (1) Preparation of fibers used

[0070] Prepare appropriate amount of viscose and chitosan fibers, weigh the fibers of corresponding quality according to the required fiber web surface density, in order to improve the carding quality, loosen the fibers by hand pulling, and spray water on the chitosan fibers for humidification.

[0071] (2) Carding of fiber web

[0072] The fiber prepared in step (1) is fed into a carding machine for carding, and the fiber web is output after carding.

[0073] The surface density of the viscose fiber web is 50g / m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com