Bracelet anode installation technology

An installation process and anode technology, which is applied in the field of offshore oil engineering, can solve problems such as coating damage, and achieve the effects of avoiding shedding failure, quick and convenient repair, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

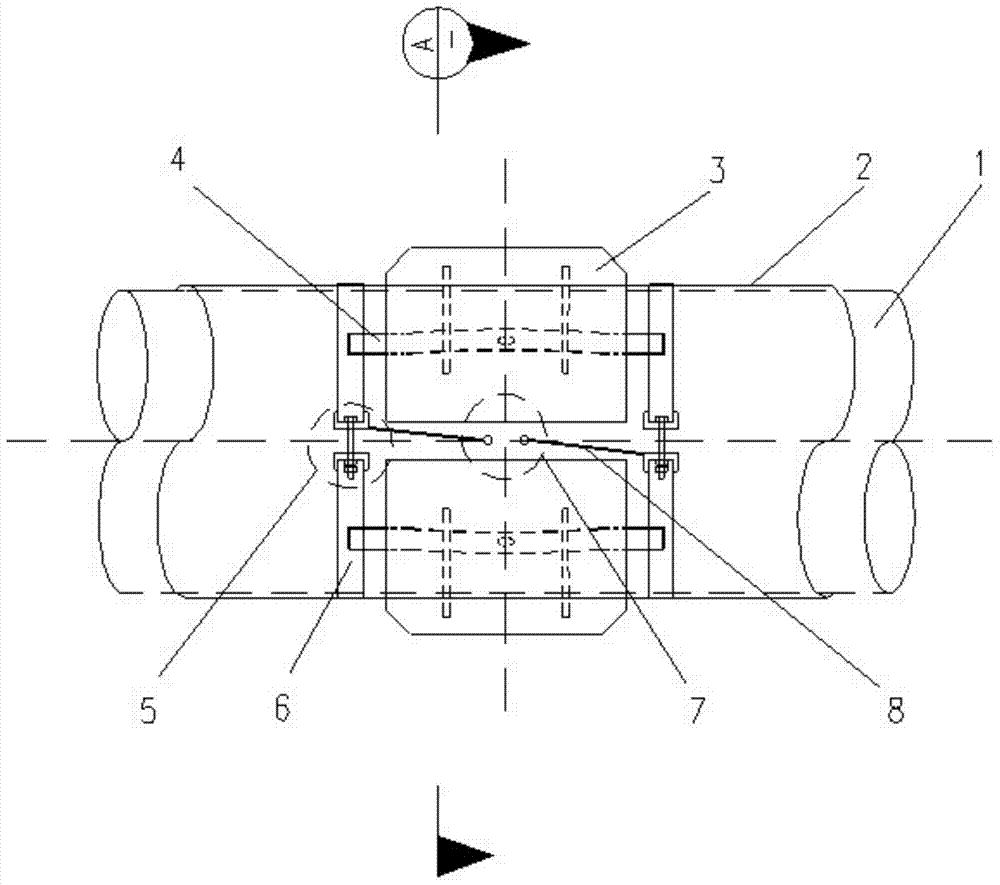

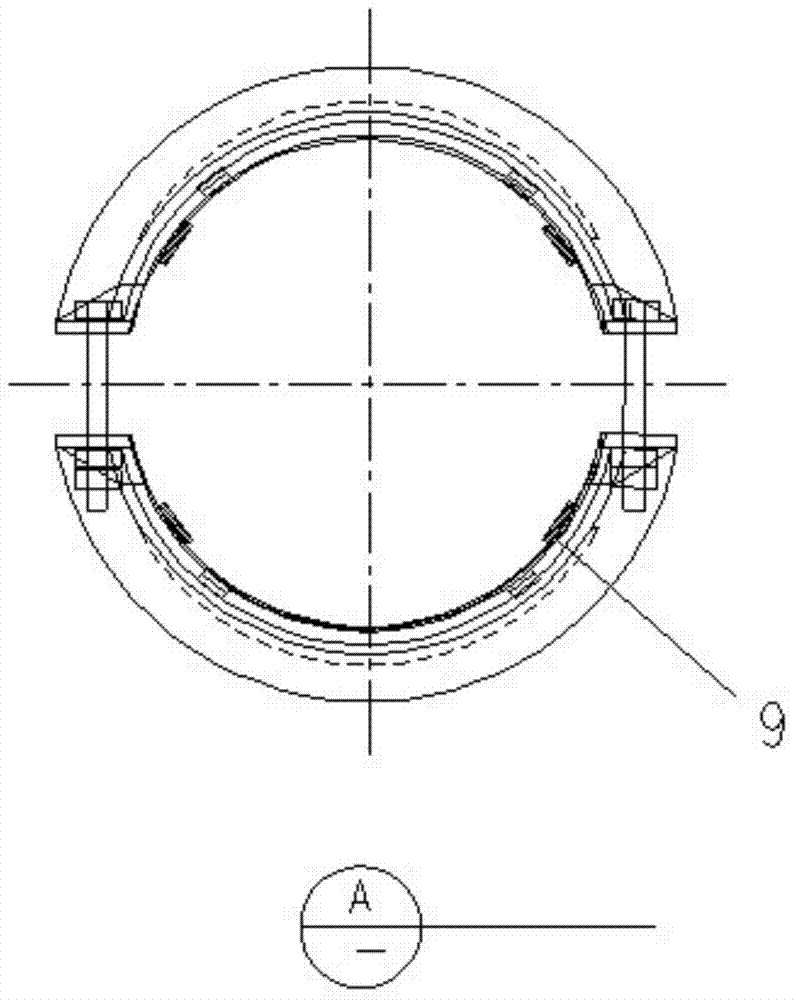

[0035] The present invention adopts the following installation steps to the bracelet type anode 3:

[0036] first step, such as figure 1 As shown, determine the installation position of the bracelet anode 3:

[0037] According to the design requirements, determine the installation position of the bracelet type anode 3 on the submarine pipeline body 1, and make a mark;

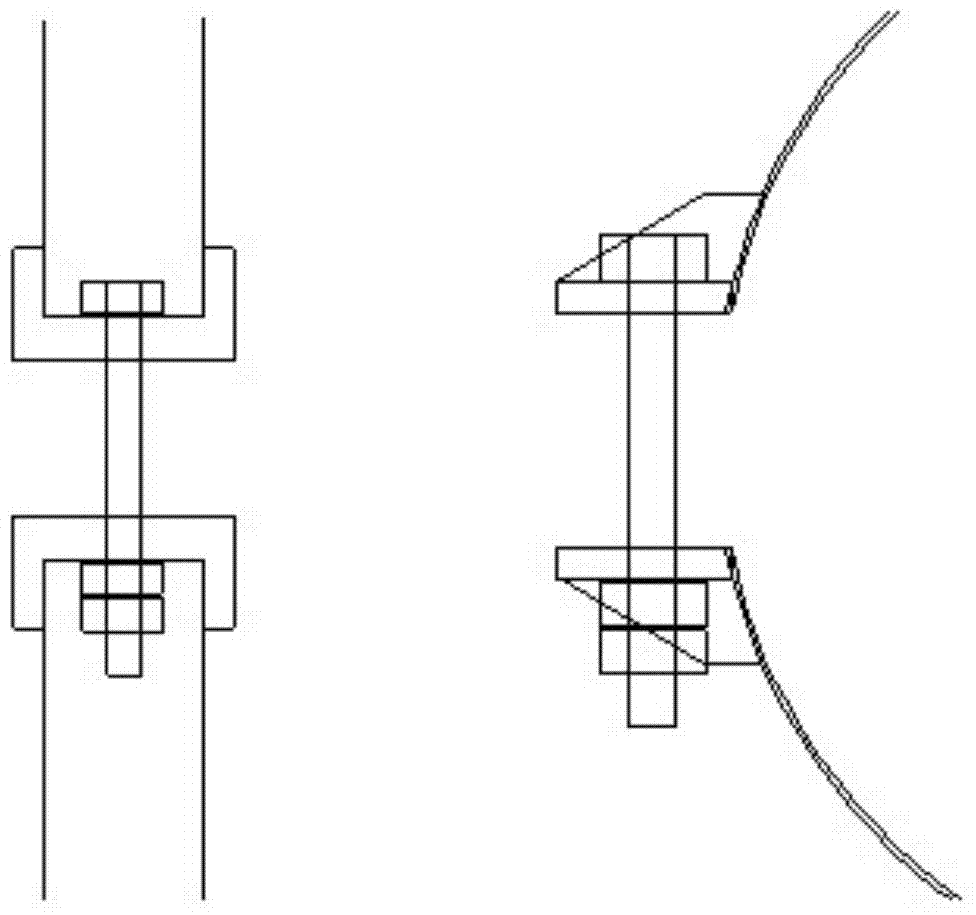

[0038] In the second step, the outer coating 2 on the brazing window portion on the pipe body 1 is stripped:

[0039] After the installation position of the bracelet-type anode 3 is determined, the outer coating 2 of the pipe body 1 at the 7 positions of the copper studs to be brazed is stripped off, that is, the outer coating 2 of the brazing window of the pipe body 1, generally not exceeding 40mm× 80mm, and use needle gun, paper grinding wheel and other tools to polish the brazing window; when stripping the outer coating 2 of the brazing window, a sample should be used to ensure the position where the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com